Varieties and sizes of furniture screws

The most functional and demanded fasteners on the furniture market today are screws. They are used in household needs, in construction, in repair and other works. For any product in the assembly, a specific furniture screw of its size, a certain material, a suitable type of slots is useful. And if the screw is chosen correctly, nothing threatens the fastening of the structure.

Peculiarities

Furniture fasteners are designed to connect furniture elements... The use of this product helps to reduce production costs, because more complicated types of clamps (thorn-groove or the so-called dovetail) will cost more. Furniture screws will also allow you to forget about gluing furniture parts. This means that the closet or bed can be disassembled, for example, for moving, but when fixed with glue, this is virtually impossible.

But screw fastening, if it suddenly remains unclaimed for its first purpose, can be useful in solving other problems. And it's not even about homemade shelves on the wall, where such fasteners are logical. In construction, in the country, in the garage, furniture screws can also be useful.

Applications

Countertops and sectional walls, cabinet and sofa parts, tables, dressers and children's complexes - this is the main area of demand for furniture screws. They are made primarily for assembling furniture, for holding hinges and fittings, for attaching handles and the like.

Such fasteners allow:

- connect chipboard sheets;

- collect furniture frames;

- fix bulky wood elements.

There are fasteners that cannot do more than one task. So, it is unlikely that shelf holders can be used somewhere else (well, except that the creative of the master will find another area of application for them).

Since today the uniqueization of the interior design of housing, the simplicity of solutions, the introduction of vintage elements, Soviet samples and homemade furniture into the interior are actively developed and supported, screws will help bring these ideas to a reasonable embodiment.

Today, indeed, they do a lot with their own hands: they assemble pretty furniture from pallets, restore old ones, and rebuild them. And furniture fasteners will be an inexpensive and solid help in this creative work.

Species overview

The purpose of the furniture screw and its design form the basis of this classification.

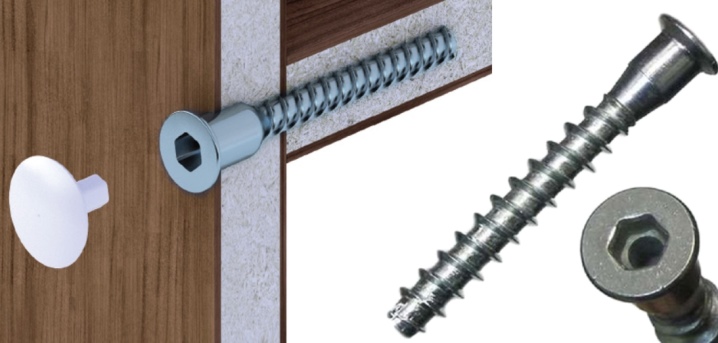

Confirmation

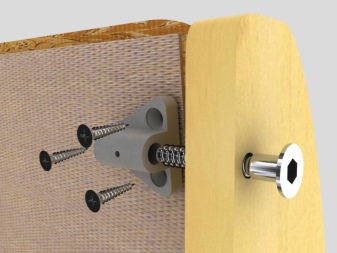

Otherwise, it is called the Euro screw. It is a cylindrical element with a countersunk head. It has slots with which the usual hexagon or cross-screwdriver will interact. This fragment of the part is followed by a smooth zone that quietly enters the pressed one. Its parameters are different, and they depend on the functionality of the object.

The usual chipboard thickness is 16 mm. That is, to fix it, you will need a fastener with a smooth part, commensurate with the length of the thickness of the plate. Therefore, for such work, screws with a 7 mm diameter and a length of 50 or 60 mm are usually used.

The application itself is based on the need to drill a workpiece. Without drilling, tightening the confirmat into the same chipboard will not work. The most demanded size of the confirmation, as already noted, is 7 mm. The size of 50 mm determines the configuration of the hexagon splines. Hexagonal screws are tightened with the same bit or with an L-shaped / Z-shaped wrench. Cross wrenches are also used, but they cannot guarantee a screed of sufficient density.

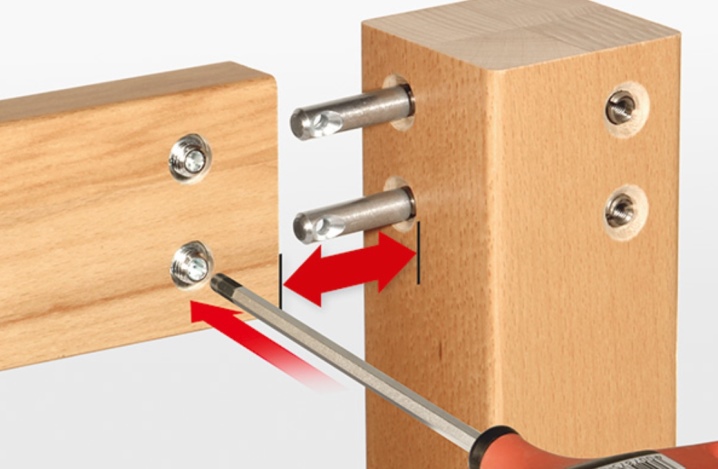

Screw tie

Such fastening includes the following: a screw with an external thread, and a barrel-nut with a different, internal thread. When the connection takes place, the parts are fastened perpendicular to each other. One workpiece with a flat base begins to press against the end of its "partner".

A through hole must be drilled in the clamping part, diametrically it will be slightly larger than the threaded screw part. And in the workpiece that the predecessor will press against, 2 holes are already drilled. The first is drilled from the end side with the same diameter as in the pressed element. Another hole is made from the flat side - it already goes under the keg. And this is difficult, because you need to precisely combine the end and barrel holes in an engineering way.

Like the Euro screw, the screw tie is mainly used in furniture assembly. It helps to increase structural rigidity that cannot be achieved with any other non-metric fastener. That is, the same confirmations and self-tapping screws of any kind as fastening are not an alternative here.

True, there were some weaknesses. Installation is quite difficult, requires skills from the master. Finally, the screw head will be visible from the outside. But this conditional minus can be masked with decorative plugs.

Intersectional coupler

It should connect furniture modules. By and large, this is an ordinary nut and an ordinary bolt, but their aesthetics are higher than standard ones. The part of the screed that performs the function of the nut looks like a hollow bolt with an internal thread, and a movable screed element is inserted into it. During assembly, the twisting refers specifically to the screw, and not to the bushing (that is, to an object with an internal thread), because the bushing has slots that will prevent it from spinning in the chipboard.

This screw is considered simple and reliable, it is made of durable metal. It tightly ties the sectional furniture pieces together. Often, with its help, kitchen sets are assembled, the same wall cabinets.

Thanks to the inter-section screed, individual parts of the kitchen set become a monolithic wall, ensuring that there are no inter-unit differences in the kitchen during the entire operation.

Shelf support with fixation

These fasteners securely hold the shelves in the furniture. It is not only a support for them, but also serves as a guarantor of strengthening the rigidity of the furniture. The object is represented by two parts: a stem and a support mechanism. The first one must be screwed into the wall of the cabinet, and the second one must be installed specifically in the shelf. The rod enters the engaging part of the eccentric system. And so the shelf is attracted to the walls of the cabinet by means of a screw rotation in the shelf holder.

This type of screw in installation can be considered not quite simple. It also requires special skills and special equipment available. Not only marking and drilling are needed for installation, milling is also required, and this is already done in the workshop on a machine.

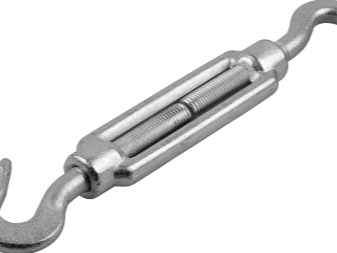

Conical coupler

These screws are also called minifixes. There is no need to drill through the details. This design resembles a turnbuckle. But the difference lies in the fastening of the stem. It will not fix in the through hole, but in the flat part of the workpiece for clamping. The parts will be articulated by pressing the stem down with the tie screw. This is how the countertop is usually attached to the base. A conical coupler is also used in fastening frame facades.

Ease of installation is definitely not about such a screed. Again, accurate marking, drilling is required, that is, the assembler must rely on his high qualifications. Silumin is used in the production of the tightening screw. Its service life is small, and therefore the number of assembly / disassembly cycles of furniture parts, alas, is reduced. In principle, experts talk about the disposability of this fastening object. For a new assembly (if required), furniture makers recommend changing the silumin tightening screw.

With decorative heads

These set screws have a standard thread connection. But they differ precisely in the shape of the head.... There is a semicircular fastener, there is a decorative one. And the choice of the latter has now become varied and interesting. Even by color, you can find good options, not just shades of metal. So, today metal fittings (steel) are being forced out of interiors. They try to replace the handles in the same kitchen section with black or bronze ones. The usual metallic goes away, which means that all noticeable fasteners also need to be changed.

Therefore, many are trying to buy fasteners that are immediately decoratively decorated impeccably. These are adjusting fixtures that look perfect in furniture designs and match the aesthetic needs of the consumer.

Materials (edit)

Furniture fastener designs must meet the requirements of solidity and be visually convincing.

What manufacturers use for:

- fasteners, made of carbon steel;

- aluminum and alloys (the same silumin) - usually it is used to create screws of complex configuration;

- brass, which is both practical and attractive - these screws are usually used in the visible areas of furniture structures or in those areas where the furniture is poorly protected from high humidity;

- plastic - usually found in shelf support housings.

Fasteners are available with a special coating, they can be galvanized, but any furniture screws must comply with the GOST parameters. Galvanized coating makes fasteners more functional, decorative qualities are also improved. Electroplated brass is even more attractive in appearance.

Dimensions (edit)

It is easier in this sense, when choosing screws, focus on the table. There are such columns as M4, M5, M6, M8, M6x30, various parameters like 8x35 and others. M is an indicator of the thread, then in the table there are the minimum and maximum values for this indicator, as well as the nominal dimensions.

If you don't feel like looking at the table, here are a couple of examples:

- the conical coupler is universal in its dimensions - 44 mm length and 6 mm diameter;

- the thickness of the confirmation is 5, 6.3 and 7 mm, and the length is from 40 to 70 mm;

- the length of the screw tie is 34 mm, the barrel diameter is 10 mm, the diameter of the screw part is 8 mm;

- furniture fixtures with a square-shaped headrest reach a maximum length of 150 mm, a diameter of 6 or 8 mm.

In building markets, furniture fasteners are sold in a separate block, where all options and sizes are divided into sections. A consultant will help you navigate the range.

Usage

Due to the fact that the most common version of furniture screws is precisely the confirmat, on its example you can see how to tighten the screw correctly.

Let's consider the algorithm of work.

- To pull together 2 parts, you will have to drill two holes, respectively. One is in the first part, and it will be commensurate with the diameter of the screw head, the second is in the end part of the second part, and its diameter is commensurate with the threaded part.

- Usually drills of 5 and 6 mm are taken for this action. But you can also find a combination drill that can drill holes at once. This is more comfortable for the assembler, since there is no need to rearrange the drills.

- You need to wrap the confirmat delicately... It's great if you can do it by hand or, if you still use a screwdriver, put it at low speed. Otherwise, the screw thread will turn into a drill that breaks the hole.

Text and video instructions help make the process of fixing furniture parts more predictable, competent and controlled.

The following video talks about furniture joining.

The comment was sent successfully.