All about corkscrews

The man has come up with many tools that help him cope with complex tasks. Wood drills are presented in a wide range. In the work, not only cutters are actively used, but also cork drills.

Description

The cork drill, or cork cutter, is used not only for the manufacture of wooden corks. Such a drill attachment is essential for those who have to work on wood.

The essence of the tool is simple. A hole is drilled through the material and the plug remains inside. If necessary (this is usually used in the furniture industry), then the cutter is not completely immersed in the wood, a piece of cork is picked out, and the necessary recess in diameter remains.

The only drawback of such a plug equipment is that it needs to be centered. Experts advise to work on the machine, you can stand, the main thing is that the material lies on a flat surface.

Plugs, which are obtained as a result of using the described tools, are used as decorative sealing of holes or bolts embedded in wood.

If we talk about the application in the professional field, then you can often see how the master easily and naturally drills out knots and other defects in the tree with the help of such a drill.

Despite their versatility, not everyone likes the drills described.... Many masters argue that it is not always safe to use them, it is much more convenient to use Forstner drills in work.

There are models that can be used in a hand router, they differ from the usual ones by the presence of a shank. It is also worth mentioning that such rigs are supplied for sale in two versions:

- conical;

- cylindrical.

If you do use a cork cutter, it is better not to use a hand drill for this. The reason is simple. In this particular case, centering cannot be done, which means that the drill can simply go to the side at any time. It will not work to achieve an even plug in this way.

Moreover, when using a hand drill, the user will have to apply additional force, but at the same time maintain a right angle between the tool and the material. It would be more convenient in this case to use a milling cutter, or a drilling machine.

Such problems do not arise if you replace the cork cutter with a Forstner drill, since the rig is self-centered, easily enters the tree and can be used with a simple drill.

Dimensions (edit)

One of the advantages of plug drills is that they come in a wide variety of diameters. In the manufacturer's table, you can find options for 15 mm, and 35 mm, and even 44 mm. In fact, this parameter can vary from 8 to 100 mm.

But it should be understood that the equipment, which has a diameter of more than 5 centimeters, is used exclusively for machine drilling. This primarily ensures the safety of the user.

On the market of modern devices, you can find sets of several drills, different in diameter, or you can purchase the product individually. Usually the direction of rotation is RH.

Diameters of 15 mm and less are considered to be among the most demanded ones. These are drills for 8, 10, 12 mm.

How to do it yourself?

If it is not possible to buy a cork cutter, then you can make it yourself. For this, an old chisel drill is used.

Tools will require a circular saw, a lathe, a clamp, and an electronic vernier caliper.

To make a cork cutter of the desired diameter, it is worth using a feather drill that has a similar parameter to the required one. In our case, the width of the scapula was taken as 4.1 cm.

First, we take a wooden block and make a hole in it with a screwdriver, suitable for the shank. We insert the equipment there, which we will change.

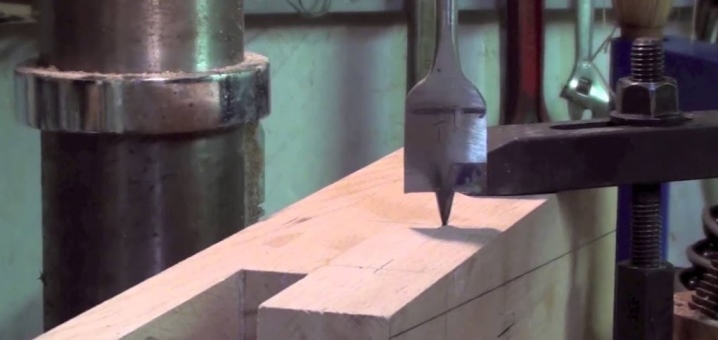

The distance between the incisors should be 3 cm, we measure it and make a notch. We insert a block with a feather drill into the clamp. It is very important to fix the part well, since the safety of the master depends on it.

On a grinding machine, we first cut off the point, due to which the centering is carried out. It doesn't need a corkscrew. Two cuts are made according to the markings drawn in advance. It is important to handle the drill upside down.

The central part is removed completely. This makes it look like a fork with two tines. During operation, such a rig easily drills a cork of a given diameter in a tree.

Sharpening

Such products can be sharpened without special equipment. This will require a special block, which must be moistened with soapy water in the process.

The material is cleaned with a solvent.

The bars are available in various grain sizes. Depending on the thickness of the plug cutter and the thickness to be removed, this parameter is independently selected by the user.

For information on how to make a corkscrew with your own hands, see the next video.

The comment was sent successfully.