All about furniture confirmations

The reliability, practicality and durability of cabinet furniture largely depend on the quality of the fittings and fasteners used in its manufacture. For screed, it is most often used furniture confirmation (euro screw)... It is preferable to screws, screws or nails. Euro screws are often used by both home craftsmen and professional furniture assemblers. These fasteners come in many different types and sizes.

What it is?

Confirmates - a variety of screws with countersunk, less often conventional heads with different types of slots. A smooth rod adjoins the base of their cap, then there is a working part with a widely protruding thread. All Euro screws have a blunt tip.

The function of the lower threads is to thread a pre-prepared hole. To facilitate this task, they are tapered and serrated.

Advantages of confirms:

- the ability to use when working with natural wood, MDF, chipboard, chipboard or plywood board;

- creating a tight screed for various pieces of furniture (even when using materials with a porous structure);

- ensuring a high speed of furniture assembly;

- obtaining a stable structure;

- ease of assembly using an available tool;

- cheapness.

Euro screws have some limitations... These include the need to hide the heads with decorative plugs and the impossibility of assembling / disassembling the product more than 3 times. Despite the fact that confirmations provide a reliable screed, they are not recommended for use on furniture, which in the future is planned to be often disassembled and reassembled.

Views

Manufacturers offer a wide range of Euro screws. They are:

- with a semicircular head;

- with a secret hat;

- with slots with 4 or 6 edges.

In the production of furniture, Euroscrew with a countersunk head is most often used. Its installation is carried out from the front of the cabinet furniture.

For masking hats, a huge selection of plastic caps and stickers in different color variations is offered. They allow you to give furniture a complete look and perform only an aesthetic function.

For the production of all types of Euro screws, high-quality carbon steel... Due to the high density of the material, the fasteners are able to withstand serious loads and not break. To protect products from corrosion, their surface is coated with brass, nickel or zinc. Galvanized fasteners are more common on the market.

Dimensions (edit)

Important parameters of hardware are their width along the edge of the thread and the length of the rod. They are designated by the corresponding numbers. The most popular sizes among furniture makers:

- 5X40;

- 5X50;

- 6X50;

- 6.3X40;

- 7X40;

- 7X70.

This is not a complete list. Manufacturers also produce confirmations with rare sizes, for example, 5X30, 6.3X13 and others.

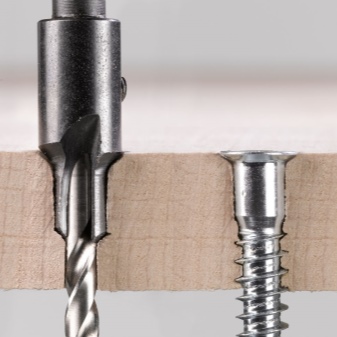

How to make a hole?

To assemble furniture using Euro screws, you need to have certain skills. For the confirmation, you need to prepare 2 holes in advance: for the threaded and smooth part of the rod. The use of several drills is advisable only for small amounts of work. Otherwise, it is recommended to use a special stepped thread drill - with its help, it is possible to perform several tasks at the same time.

Before making a hole, it is important to select the correct size of the drill. Even minor deviations can cause the hole to come out.

For example, for a 7 mm Euro screw, you will need to make the threaded part with a 5 mm drill, and the non-threaded part with a 7 mm tool.

To make holes, you cannot do without a screwdriver or drill. It is recommended to screw the drill into the material at high speeds. The high rotation speed will prevent chips from clogging the hole. Remove the drill from the resulting recess with extreme caution - this will help to avoid the formation of unwanted chips.

When drilling parts, the drill should be placed in a strictly perpendicular position. Thanks to this approach, the risks of damage to the part are significantly reduced.

To make the connection reliable, also it is recommended to pre-mark... To facilitate the work, you can use special conductors. This is the name of templates or blanks with finished holes. They must be applied to the surface of the furniture and marked with markings. Conductors can be made independently from a metal or wooden blank, or you can buy a finished product at a hardware store.

How to use?

Before fastening furniture parts using confirmations, it is important to align the corresponding elements evenly. Their displacement is unacceptable. Due to incorrectly aligned parts, the functions of movable structures can be impaired, as well as the aesthetics of the furniture. To avoid these problems, a number of recommendations should be followed:

- you should not try to screw the hardware into the prepared hole from 1 run - it is best to stop at the level of the hat entry into the part, make the necessary corrections and only then tighten the tie;

- when working with excessively porous or loose building materials, it is advisable to apply an adhesive composition to the thread;

- if the furniture has drawers, it is not recommended to screw the sidewalls all the way to the end - first you need to check the functionality of the moving elements.

To install the Euro screw into the prepared hole, you need to use a hexagon. With the careless operation of cabinet furniture from chipboard, the owners often face the tearing of the hinges.

In this case, it is impossible to re-install the confirmat into the broken socket - first you need to restore the hole. To do this, you need a wood insert.

You can make it yourself from a wooden lath. Procedure:

- measuring the thickness of the chipboard;

- making a hole with an optimal depth (for example, if the material is 10 mm thick, you need to make a recess no more than 8 mm);

- the thickness of the drill must be selected based on the diameter of the Euro screw and the nature of the damage;

- preparation of a wooden insert according to the diameter and length of the hole;

- processing the edges of the groove with glue (PVA is suitable);

- driving a wooden insert into the prepared recess.

After the glue has dried, it is necessary to drill a hole for the Euro screw, and then install the fasteners with the appropriate size. In this way, you can restore a broken nest not only in chipboard, but also in any other lumber.

For minor damage, some craftsmen advise to fill the formed cavity with epoxy resin.

In this case, it is necessary to top up the composition several times. After its final drying, you can make a hole again for the subsequent installation of the euroscrew.

The comment was sent successfully.