All About Calcium Silicate

Calcium silicate is a popular material that is in demand in various fields. Although in its pure form it is a powdery substance, all kinds of products can be made from it, for example, refractory boards, which are used for facing fireplaces and stoves. And also the material is used in food production and the pharmaceutical industry.

Properties

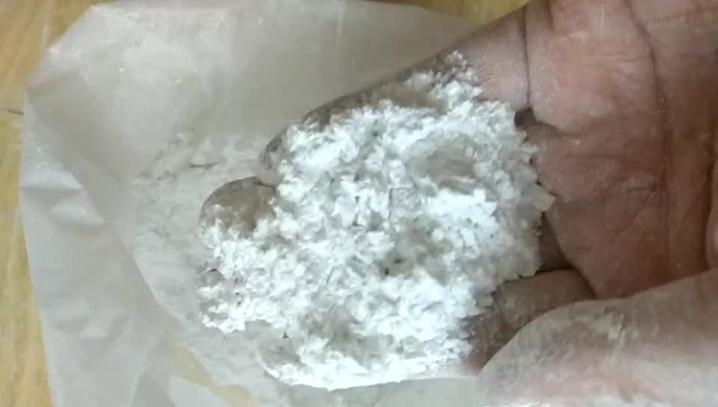

Calcium silicate belongs to the group of inorganic substances. Outwardly, it looks like a white or colorless powder. It has no taste and smell, and also the substance does not dissolve in water, and is a good adsorbent - it can absorb liquid. At the same time, he is afraid of the effects of strong acids.

There are various modifications of calcium silicate:

-

orthosilicates;

-

hydrosilicates;

-

pyrosilicates;

-

metasilicates.

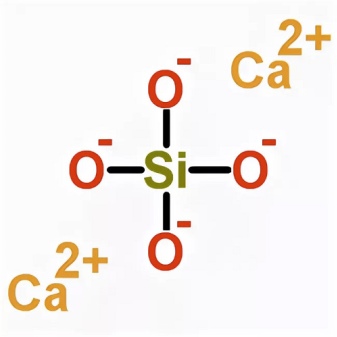

They have certain differences in the chemical formula, although three main components invariably remain among the main components of the compound: Ca, Si, O.

Some of the important characteristics of the material are heat capacity, incombustibility and the ability to withstand direct exposure to flame. The refractory insulation board made of calcium silicate has the following properties:

-

can resist temperatures up to 1100 degrees, the time depends on the thickness of the plate, on average, such products can hold back the flame from 30 minutes to 2 hours;

-

does not emit toxic smoke, making it possible to evacuate in case of fire;

-

fire-resistant materials are quite light, which is convenient for installation and work with them, also the low weight does not make the walls heavier and eliminates the need to install additional lathing;

-

mold and other types of fungi do not form on the sheets, rodents, insects and other pests will not be interested in them.

Thermal insulation boards are used for finishing fireplace and stove areas in those places where there is a potential hazard associated with accidental fire. The material avoids the spread of fire. Products are available in different sizes and thicknesses, so you can choose the best option. The most popular parameters: 1080x950x30 mm, 1500x1250x60 mm, 1000x625x40 mm.

Dimensions may be different, it all depends on the plant that produces sheets.

How is it produced?

The substance is obtained by synthesis in a laboratory, and is also obtained naturally. There is the mineral wollastonite, which is almost pure calcium silicate, with the exception of small amounts of titanium oxide, manganese and iron oxide. In production, the material is synthesized from other natural components: feldspar, mica, clay.

This is how refractory sheets are made.

-

Silica and lime are used as ingredients for obtaining the substance. A chemical reaction takes place between them, resulting in the formation of calcium silicate.

-

The basis for the board is a fiber material with high strength. This is a reinforcing frame.

-

Calcium silicate is applied to the substrate and left for some time to crystallize. In the course of this process, a high-quality seamless board with high fire resistance rates is obtained.

Sheets made of this material have a smooth surface, which makes them suitable for any decorative work. You can fasten the products together with self-tapping screws, and the joints are easily covered with mastic. Plates can be cut without great effort if necessary for installation.

The most active substance is produced in Denmark and Germany, the leaders are Skamol and Calsitherm. In Russia and in other countries there are also plants producing calcium silicate.

Chinese products are no less popular due to their affordable cost, but in this case there is a risk of stumbling upon substandard goods.

Applications

Depending on the shape of the material, there are different ways to use it.

-

Silicate boards are used for facing fireplaces and stoves, for decorating boiler rooms, as an additional insulation for better thermal insulation. They are suitable for residential and public buildings as well as technical facilities.

-

The powdered form of silicate is in demand in the food industry. This additive is labeled E552. It is used to prevent sticking and clumping of various bulk products.

-

Crystals can be a part of medicines and dietary supplements, as well as ointments and cosmetics.

-

A synthetically obtained substance is added to cement, paints and varnishes, primer and plaster.

-

Silicate is also one of the components in the manufacture of porcelain.

-

In agriculture, the substance is used as a fertilizer, as a source of silicon, which is necessary for some plants.

Naturally occurring calcium silicate is used where it will come into contact with food, cosmetics or medicine.

The synthesized substance with additional additives that improve the performance characteristics is used in other fields.

Restrictions on use

In many countries, calcium silicate is recognized as conditionally safe. Its use in the food industry is allowed, but in limited quantities and in accordance with sanitary and epidemiological standards. In Russia, this substance cannot be used for food production. This is due to the insufficient amount of research needed to gather the evidence base and determine a safe daily value. As for the use of calcium silicate for the manufacture of building materials and other products that are not related to the food or medical field, there are no restrictions.

The comment was sent successfully.