Facade planken: types of material for finishing country houses

The cladding of external and internal walls always looks elegant and high-status. It is also important that it is completely environmentally friendly. Such obvious disadvantages of wood, such as the tendency to absorb moisture, rot, deform, today are leveled due to special processing. As a result, durable, moisture-resistant materials appear that tolerate temperature changes and the effects of negative environmental factors. Planken is one of them.

Peculiarities

Planken is a type of board, a wooden facade material, which, however, is also used for the interior decoration of a room. It features beveled or rounded corners, which is achieved by chamfering (beveling the corner edge) on all four sides of the material.

Outwardly, it resembles a ship's board, however, the planken is thinner (from 15 to 22 mm). The material reaches 70–140 mm in width.

Such types of wood as larch, oak, pine, ash, cedar often become the basis of the board. Planken from these tree species, like their WPC products, are characterized by durability and can be used for up to 25 years without requiring repair.

The material has a wide range of applications, in particular, it is used to perform the following types of work:

- organization of a ventilated facade of a house, outbuildings, a bath;

- floor and ceiling decoration, railings on verandas and terraces of a country house;

- construction of fences, fences of a private house;

- creation of benches and benches;

- production of elements for playgrounds for children;

- surface cladding as horizontal decking.

Unlike the lining, the plank does not have a “thorn-groove” system, therefore, when exposed to moisture or high and low temperatures, it does not warp or twist. And in case of damage, if the installation was made in an open way, it will not be difficult to replace the necessary element. With a hidden installation technology, it will be necessary to disassemble the part that is located above the board that requires replacement.

Advantages and disadvantages

The board is characterized by dimensional accuracy and impeccable geometry, which is achieved through an automated manufacturing process. Naturally, this facilitates installation and allows you to get the most flat surfaces.

Due to the sorting of the material, as well as careful control of all stages of production, the planken set contains almost no scrap.

In other words, buying it is economically profitable.

Among the advantages are the following:

- high resistance to temperature changes and humidity indicators;

- improved performance of sound and heat insulation;

- long operational period, due to the careful processing of wood, the absence of knots, resin pockets on the material;

- impressive vapor barrier performance, due to which the wood "draws" excess moisture from the room, and then from the surface of the walls;

- ease of installation, easy replacement of the damaged area;

- no warping and deformation;

- biostability;

- variety of colors and textures, exquisite and noble design;

- wide range of applications.

These advantages are achieved due to short-term heat treatment of the boards. Heat-treated material withstands various environmental influences without losing its aesthetic appeal.

The presence of a topcoat makes the planken resistant to UV rays. As you know, under the influence of such radiation, the tree dries out, cracks and loses its color. Heat-treated and then coated with a finishing layer, the boards retain their high technical characteristics and attractive appearance throughout their entire service life (20-30 years).

The disadvantage of planken is its high cost.

It is believed that even taking into account the use of high-quality materials, the price of the boards is overpriced. Some experts agree that it is due to the novelty of the material.

In addition to the purchase of planken, you will have to spend money on special fasteners, as well as a special light-resistant hydro-windproof membrane, a conventional waterproof film with an open type of installation will not work.

Varieties

Depending on the method of cutting the chamfers, there are 3 types:

- straight (mounted end-to-end while maintaining small gaps);

- beveled (parallelepiped-shaped, stacking is carried out end-to-end);

- straight line with pages (equipped with a special "crab" or "bridge" mount).

Depending on the type of material, there are:

- boards of the "Extra" class - are of the highest quality, do not have chips, damage and resin pockets on the surface;

- "Prima" products - small flaws and surface cracks are acceptable;

- board class "AB" - in addition to cracks, other flaws are found, for example, knots;

- "VS" boards - significant surface defects, the presence of knots, dark areas.

Planken can also vary depending on the material used. Larch products are widespread, which are characterized by the ability to tolerate high humidity well, while maintaining their parameters and geometry. Moreover, under the influence of moisture and high temperatures, they acquire additional strength and hardness.

This type of wood does not lend itself to attack by pests, which is why the finished board retains its integrity. The specified characteristics ensure durability, the service life of larch planken is 25 years.

Larch products are attractive and versatile.

They go well with other materials, be it parquet or artificial stone.

Canadian cedar and pine are also used for cladding. Strong, durable, with a characteristic pattern, the product becomes a worthy option for interior work and facade decoration.

The version made of wood-polymer composite (WPC) has high performance characteristics. Its basis is made of pine wood, ground to crumb, which is filled with polymers. Thanks to this composition, it is possible to obtain a material that is completely not subject to decay, characterized by weather resistance, moisture resistance, and a long period of operation. WPC planken tolerates both high (up to + 70C) and low (up to -50C) temperatures, as well as thermal "jumps".

Finally, heat-treated planken is also isolated, which, thanks to a special treatment, has a high biostability, is not subject to deformation and is characterized by lower weight.

main parameters

As already mentioned, the thickness of the boards is about 15–22 mm. However, if necessary, planken is produced with a greater thickness. The thickness of the material directly affects its insulating properties, as well as its service life.

The width of the boards is from 90 to 140 mm. Narrow products (70-120 mm) are usually used for interior decoration, wider (120-140 mm) - for outdoor. Length - from 2000 to 3000 mm. Some manufacturers offer options up to 4000 mm in length.

Installation methods

Usually boards are mounted horizontally. However, nothing prevents you from fixing the plank in the vertical or diagonal direction. It is easier to install the material horizontally, it requires special professional skills.

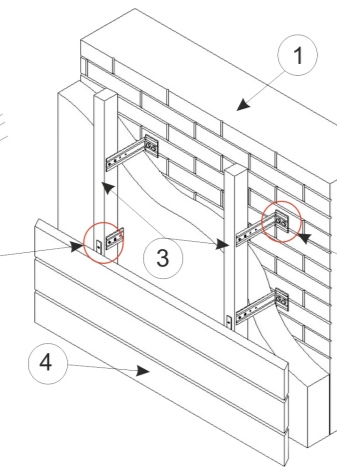

There are two mounting methods: open and closed. The first installation option is suitable for beveled boards. It is laborious and takes more time, however, the result will be the effect of a monolithic wall of wood, since the joints and fasteners are not visible. In the absence of skills in working with the material, it is better to entrust the closed fasteners to a professional.

Installing an open system is easier. It implies fastening the boards to the crate using self-tapping screws, therefore, with this method of fixing, the fasteners become noticeable.

Sheathing stages

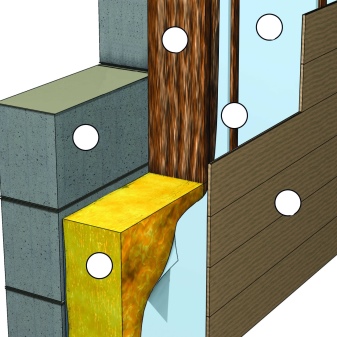

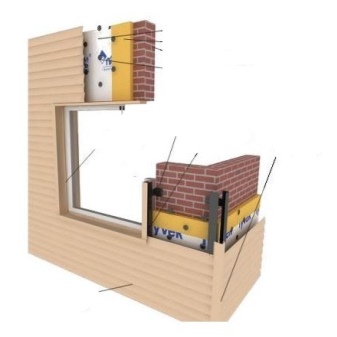

First of all, it is necessary to install a crate, which is made from larch bars that have undergone antiseptic treatment. Using screwdrivers, they are fixed to the wall over the heat-insulating material. The logs are located at a distance of 100 cm from each other, their direction corresponds to the direction of the boards.

If the previous coating is strong (brick cladding), it can be retained. It is better to knock down the plaster, dust the surface.

The step of the lathing is usually determined by the width of the insulation sheet.

Since the most common thermal insulation material is mineral wool with a layer width of 60 cm, the pitch of the lathing will be 56–58 cm. When choosing another material, be guided by the fact that the insulation should fit tightly between the elements of the subsystem.

Before use, planken is treated with an antiseptic that increases the moisture resistance of wood. When cutting material, it is important to process the cut points. If you plan to paint or apply another decorative coating, then it is better not to cover the front sides with an antiseptic. Further paintwork may be uneven.

Installation starts from the second row.

First, a laser level is used to mark and fix the bar. A board is placed on top of it to outline the location of the fasteners.

On the back side of the plank, the fastener should be mounted in such a way that the fastener element for the self-tapping screw remains in its upper part. Then it will be screwed to the lags (lathing beams), and the lower one will be fixed to the fasteners of the upper part of the previous board.

The subsequent rows are performed in a similar way. After completing the work, you should remove the bar under the second row and proceed with the installation of the first. To do this, a corner is fixed on the reverse side of the planken and fasteners are made. It "hides" behind the second row, and the corner from the bottom is fixed to the lags. The result is a flat surface, all gaps are hidden from prying eyes and the influence of the external environment, which increases the service life of the fastening system.

Installation of the beveled plank is carried out using a special fastening element - planfix. This is a metal plate in the shape of the letter "L", which allows you to fix boards up to 25 mm thick.

The mount has a special spike on which the boards are mounted. Installation also begins with the thermal insulation of the building and the installation of the subsystem. The first row is attached to the crate with bolts or self-tapping screws. Next, the planfix is connected to the sheathing bar and the board of the first row. After that, the "strip" of the next row is pushed onto the spike of the fastener. All plankens are fixed in the same way.

Recommendations

If you want to get a surface on which the gaps between the boards will not be visible, choose a beveled plank. with an angle of inclination from 45 to 70 degrees. It is also recommended for regions with high humidity levels. Beveled edges and a hidden installation method exclude the formation of joint gaps between the boards, which means that any possibility of moisture penetration through them is excluded.

It is recommended to use fasteners made of stainless steel or other materials for installation.with anti-corrosion coating. The outer surface of the planken after installation must also be protected - it can be coated with linseed oil, varnish or special paint.

Experts recommend leaving a small gap between the boards, since during operation they may slightly increase in size.In the absence of a gap, deformation of the coating cannot be avoided.

Original examples

Planken looks equally impressive both on large areas and when used on compact buildings. The style of the building is also not of paramount importance - the material, correctly selected in color, looks harmoniously in the exterior of any style.

Its use in interior decoration adds refinement, luxury, comfort and warmth to the interior. Planken can be painted and combined with other finishing materials.

For more information on cladding the facade with planken, see the video below.

Video commentary: Why install vapor protection from the street side? I believe that in this case, moisture will remain in the insulation ...

The windproof film does not act as a vapor barrier. And it is she who is put, and not the vapor barrier.

The comment was sent successfully.