Modern exterior decoration of aerated concrete houses

The widespread use of aerated concrete blocks is due to their affordable price, lightness and durability. But the problems may be due to the fact that this material does not look very good. A high-quality exterior decoration of a house or other building helps to improve the situation.

Peculiarities

The construction of urban and suburban buildings from finished parts of industrial production is becoming more popular from year to year. But do not think that the exterior wall decoration of aerated concrete houses will negatively affect the overall price of the structure or worsen its practical qualities. As practice shows, it is not at all necessary to make a finishing layer or mount hinged screens that completely mask the unattractive masonry. Of course, all types of finishing materials and elements are selected taking into account the increased permeability of aerated concrete to water vapor and its tendency to absorb water.

Finishing blocks from the outside, according to experts, does not always require the creation of an insulated layer.

If the elements used are thicker than 40 cm, then in the usual climatic conditions of the Russian Federation (except for the northernmost regions), the material itself provides a decent level of thermal protection. Considering that aerated concrete is purchased most often in order to save on construction, any additional materials and structures should be cheap. Mechanized application of plaster mixes (if it is decided to use them) is quite possible. For this purpose, both industrial and home-made devices are used.

Advantages and disadvantages

Anyone who wants to save money as much as possible and simplify their work, a natural question arises - is it worth finishing aerated concrete or not? In many information materials, one can find the statement that the decorative layer has a purely aesthetic purpose and is not practically necessary. But in fact, there is at least one plus - it is necessary to trim aerated concrete because it allows a lot of water vapor to pass through. In this case, the finishing material should be selected with exactly the same level of vapor permeability, which limits the choice. If you violate these rules (do not finish aerated concrete from the outside or do the coating incorrectly), you can face a sharp reduction in its shelf life.

Brick

It is impossible to cover an aerated concrete wall with bricks without preparing a mobile sheet, the thickness of which is 4 cm. This sheet will provide a technical gap from the wall to the masonry. In the resulting gap, air will begin to circulate, therefore the problem of the different abilities of the two materials to pass steam is automatically solved. Before overlapping the outside of a private aerated concrete house with brickwork, you need to make sure that the foundation can withstand the increased load. Ideally, such a decorative element should be incorporated into a working project.

It should be borne in mind that brick finish:

- increases resistance to water;

- makes the structure stronger;

- very difficult to execute;

- costs a lot of money.

Siding

Sheathing a house with siding can be much faster and cheaper than finishing with bricks. A wide range of color and texture options will undoubtedly delight home owners. Aerated concrete blocks can be completely covered from water penetration, moreover, such a finish is very durable and does not burn.Siding does not create a significant load on the foundation and is resistant to ultraviolet radiation. It is not difficult to take care of it, to maintain the surface in good condition.

You can often hear that siding does not tolerate mechanical destruction. But this is not too important, because you can easily and quickly replace the damaged blocks with completely new ones. Given the relatively low strength, it is worth taking the coating with a margin. And even if the entire installation went well, there is no need to rush to send this stock to the trash. It may turn out that after a few months or years it will not be possible to find siding sheets with the same color.

Ventilated facades

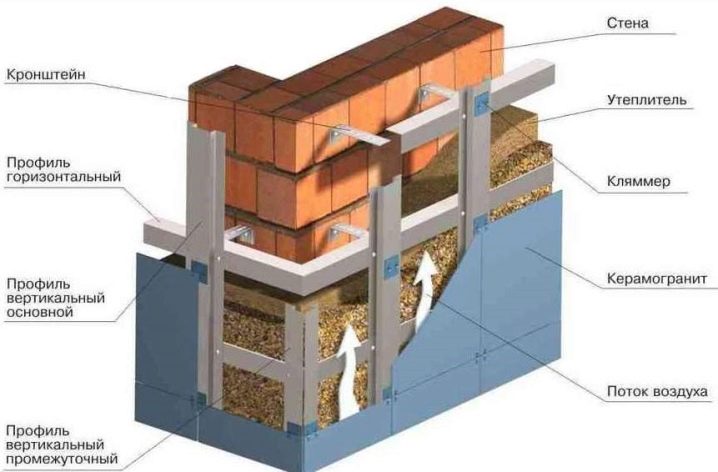

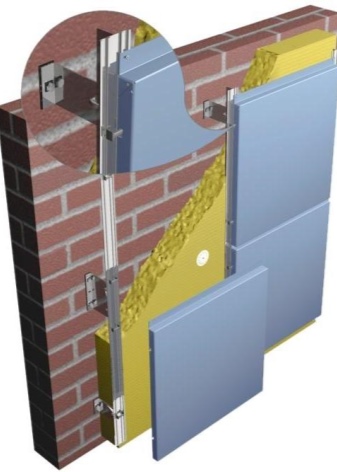

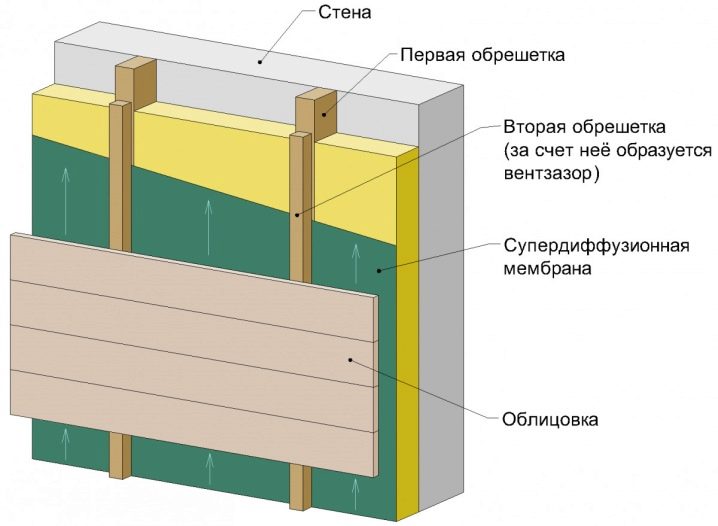

Facades with an internal ventilation gap are perfect for decorating aerated concrete houses. If they are made in strict accordance with technical rules, it will be possible to provide both a beautiful appearance and reliable protection of the base material from bad weather. The heating rate of the interior will increase, and the heat energy will spread more evenly through them. Accordingly, the cost of heating resources will be lower. Ventilated facades on aerated concrete can only be insulated with materials permeable to steam.

In addition to mineral wool, it is necessary to place a membrane that protects against moisture, which must also allow steam to pass through. This solution will ensure the timely drainage of condensate to the outside. It is impossible to use expanded polystyrene for insulation, because it will interfere with the release of water vapor, and very soon the wall will begin to deteriorate. The use of ventilated facade technology, along with improved thermal protection, will damp street noise. But this method is unacceptable near water bodies or in areas where there is a lot of precipitation.

The ventilated surface immediately changes the appearance of the building. It can be modified in accordance with any chosen design approach. The facade will be able to serve up to 70 years, and the absence of "wet" works allows installation regardless of the weather situation. You should start work only after the completion of all internal work that contributes to an increase in the concentration of moisture.

To fasten the ventilated facade to aerated concrete, use:

- spring-type expanding dowels;

- dowel-nails nylon for universal use;

- chemical anchors;

- mechanical anchors.

Tile

Facing aerated blocks with clinker tiles is no worse than other finishing options. It gradually pushes brickwork into the background. It is important to take into account that simple clinker application (gluing to the wall) will do nothing. Aerated concrete will dry out the glue mixture in a matter of weeks, whatever it is, and after that the tile will begin to crumble to the ground. This should not be allowed.

The initial layer is applied with metal or fiberglass mesh reinforcement. Then you need to put an additional final layer of plaster and level it. Only after all the plaster has completely dried can the tiles be installed. To do this, use glue varieties that are resistant to cold and moisture, create a large seam between the tiles. The minimum gap dimension is ¼ of the area of the cladding element.

Intermediate reinforcement with steel or plastic dowels will help to improve the bond between aerated concrete and ceramic plates. They can be replaced by ordinary nails or stainless screws. In all four cases, it is required to drive the fasteners into the masonry and mask it in the seams between the parts of the clinker array. Experts believe that you need to do 4 or 5 attachment points per 1 sq. m. Then the cladding will hold securely and will not collapse prematurely.

Plaster

The plaster layer can be created not only as a basis for a ventilated facade or clinker tiles. With the proper selection of the mixture and the correct execution of the work, it in itself will become an attractive design solution.It is recommended to use only specialized facade plasters. When working with acrylic compounds, you can count on the long-term preservation of useful qualities, but you should beware of open fire (the material can easily ignite).

The silicone plaster, which absorbs little water and is relatively inexpensive, demonstrates a wide variety of textures, but a meager color range. It should not be used where a significant amount of dust and dirt will get on the walls. The gypsum composition dries quickly and is not subject to shrinkage, and only one layer is enough for decoration. But one has to reckon with a low level of vapor permeability and with accelerated wetting under the influence of precipitation. In addition, the surface of the gypsum is often covered with spots, they will have to be painted over right away - there are simply no other ways to fight.

Painting

But since in this version, you will still have to paint the aerated concrete wall - it is logical to look at the use of paint. Paints and varnishes of this kind are divided into two groups: some contain reinforcing fibers and give texture, while others form an attractive relief. Both types of paint mixtures can be applied to aerated concrete blocks with a simple roller without additional manipulation. The created layer has a matte sheen, the tonality of which can be easily adjusted by adding color. Paints and varnishes for aerated concrete are guaranteed to work for at least 7 years and will absorb a little water.

This solution eliminates cracking, and the developers' refusal to use a water-based organic solvent helps prevent bad odors. Before applying paintwork, it is required to remove all dust and smooth out minor defects with a float. Painting is carried out either immediately or on the front filler (depending on the complexity of the situation).

Criterias of choice

As it is already clear, the external decoration of aerated concrete walls can be performed using a variety of technologies. But the manufacturers of each coating are trying to attract the attention of consumers, telling that they have all the best and most reliable, that it is their solution that is ideal for gas blocks.

It is categorically unacceptable to use in decoration:

- sand and concrete plaster;

- Styrofoam;

- expanded polystyrene;

- covering paint that forms a film.

Simple black self-tapping screws for attaching the battens under a ventilated facade should not be used. Dowel-nails proved to be much better in practice. They do not form cold bridges and are not subject to the harmful effects of condensing moisture. The assembly pitch is reduced to 0.4 m - this allows for the most even distribution of the wind shock load. If it is decided to finish the aerated concrete wall with bricks, you will have to provide for air vents in the lower part of the masonry, and also take care of closing them with gratings.

For your information: brick is worse than other options, because its use creates an increased load on the foundation.

Even if the masonry is ½ brick, a significant mass is still created. You will also have to take care of flexible connections between the main and external walls. Summing up, we can confidently conclude that the best results are obtained by using a ventilated facade. Only this technology guarantees both external beauty and resistance to weathering.

Successful examples and options

This is how the "cake" of aerated concrete wall decorated with bricks looks like. The work is still underway, but it is thanks to this that you can see the structure "in a cut", how it works.

The appearance of silicate plaster is no worse - and at the same time it does not take up precious space.

This photo shows how elegant and attractive clinker tiles can be, if they are picked up properly.

This diagram will help you get an idea of the internal structure of a ventilated facade on aerated concrete.

The cladding of gas-block walls with facade panels without crate with self-made fittings is shown in the following video.

The comment was sent successfully.