All about minerite

The modern construction market is gradually replenished with a variety of competitive new generation materials. Undoubtedly, attention should be paid to the multifunctional fiber cement slab - minerite, which is fireproof, moisture resistant and environmentally friendly in its composition and properties. Namely, increased requirements are now being put forward for safety as a paramount factor of well-being, especially during construction or interior decoration of premises.

What it is?

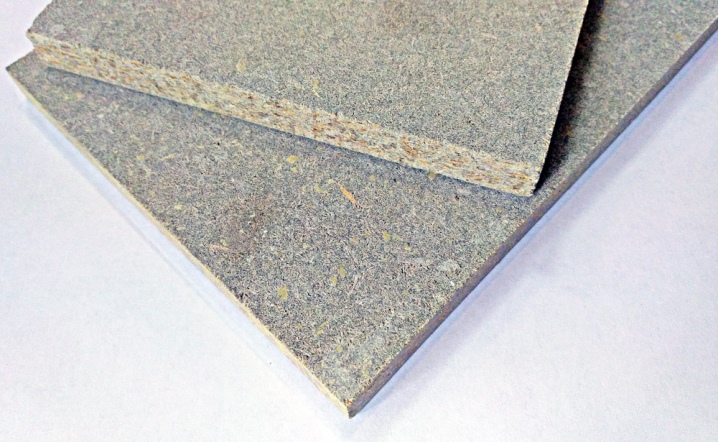

Minerit was first presented by a Finnish manufacturer who has developed an improved technology for the production of cement slabs. The world owes the appearance of fiber cement to the Austrian Ludwig Hatchek, who developed this material at the end of the 19th century. The inventor experimented for 7 years, combining cellulose with cement and reinforcing fibers to create a tough yet lightweight and practical heat-resistant material. Now, instead of mineral fibers, artificial ones are used. With the help of dyes, the material is given a more attractive appearance, and the strength is increased by adding hardeners to the mixture. But the very idea of fiber cement remains unchanged.

Composition:

- 70% is cement;

- 10% - cellulose;

- 20% - minerals.

The material under discussion has excellent performance, allowing it to be operated in rooms where humidity indicators are above normal and critical temperature drops.

Withstands temperature conditions in the range from -80 to +150 C. At higher temperatures, the process of cellulose decomposition and damage to the board begins. The material demonstrates excellent performance in the following qualities.

- Durability and long life.

- Moisture resistance and frost resistance.

- Stable against alkalis and oxidation.

- Environmental friendliness and safety.

Applications

The multifunctionality of minerite justifies its demand for various types of work.

- Fiber cement boards are suitable for installing screens around hot stoves, hot fireplaces and heat dissipation equipment in saunas.

- Fire-resistant partitions are built from minerite slabs, dividing the area into fire zones, equipping a safe escape during evacuation. According to a certain technology, walls, ceilings, chimney systems, ventilation ducts are sewn up in fire hazardous zones.

- High moisture resistance allows the use of this material where there is excessive moisture and humidity (showers, swimming pools). In this case, additional treatment with waterproofing (aquablocks) is not required.

- Can be used as a base for tiles and other waterproof finishing materials.

- Thermal insulation and excellent adaptation of the material to temperature extremes presupposes its use for cladding interior and exterior walls of buildings, including loggias and balconies.

- Serve as a smooth, waterproof base under wood stoves, wall and floor tiles.

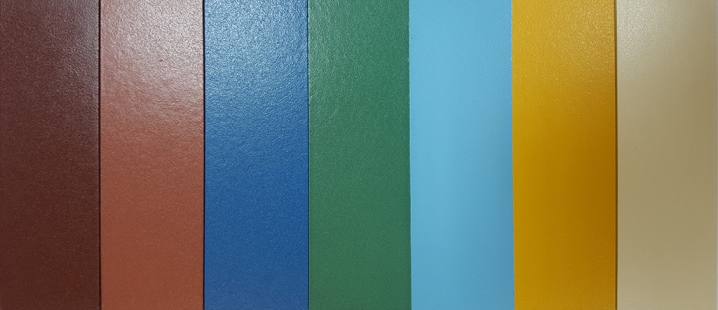

With a moderate weight, the slabs are characterized by increased strength, impact resistance and durability. It is also important that the components of the minerite contribute to the self-cleaning of the slab surface. And in addition to excellent structural properties, the material is endowed with aesthetic possibilities. Plates are produced in different color variations.Various decorative coloring of the front part of the coating allows sheathing facades with minerite during the reconstruction and construction of residential and administrative buildings.

Characteristics and properties

Minerite slabs are available in two sizes: 1.2 and 3.6 m long, 45 cm and 1.5 m wide, respectively. The plate weighs about 25 kg. The material is imported to Russia from Europe and its price is influenced by the euro exchange rate. The minerite slab is an expensive building resource, but the availability of domestic counterparts allows you to save a little. Fiber cement panels of Russian production not only do not lose to foreign ones in terms of technical characteristics, but also surpass them in a number of characteristics.

The products have the appropriate technical documentation and a certificate that allows their use in construction on the territory of the Russian Federation.

Minerite has the following properties.

- High strength and shock resistance. Under the influence of loads, surface deformation does not occur.

- Absolute fire resistance. The material remains virtually unchanged at temperatures reaching 150 degrees.

- The panels do not deteriorate in a humid environment. Thanks to water repellents, the plate does not absorb moisture, which quickly evaporates from the surface of the material.

- It tolerates temperature fluctuations perfectly.

- Mold resistant.

- Stable against alkali and acids.

- Good soundproofing.

- Clean material in an ecological sense.

- It guarantees a long service life.

These characteristics refer to the benefits of minerite. But, like all building materials, it has weaknesses. In this case, the disadvantage is fragility. Therefore, it is important to cut and cut it into fragments with the utmost accuracy. Another disadvantage is thermal conductivity, which can be completely solved by taking certain measures during the installation process.

Species overview

- Windproof. They are used for finishing facades, building using frame technology, when the slabs act as a structural material and have the functions of wind and water protection. Minerite sheets of modification ВЗ are produced in sheets in the following sizes: 900х2700 mm; 1200x2700 mm.

- Construction, HD modifications. A versatile material suitable for indoor and outdoor cladding of buildings. Such cladding does not deteriorate during critical changes in temperature and humidity. The panels are distinguished by their high strength. Sheet thickness 3.2-10 mm, determined by purpose. The most popular slabs are 8 mm thick.

- Flat PC panels for fastening to facades. This type is based on HD modification plates. The material is primed on both sides, and a durable acrylic layer is applied to the panel from the front. Colored panels are available in four different sizes.

Possible thickness 6 or 10 mm.

- "Pastel" facade slabs with a water-repellent coating and a smooth painted surface.

- Thermostable, refractory sheets. Designed for installation on wall and ceiling structures to protect them from the effects of heat, for decorative cladding of fireplaces, etc.

- Decorative. Manufacturers produce products with a textured surface that imitates various finishing materials. For example, “stone-like” minerite is a very good option for arranging living spaces and paired complexes, for creating fire safety conditions, soundproofing with insulation and visual aesthetics. Along with the declared durability, they look very decent. Many consumers prefer colored slabs for interior work, despite the fact that it costs a little more. The color of the slabs comes in different shades, depending on the type of cement used.

Comparison with other materials

Thinking about how best to choose a material, you need to proceed from specific tasks. For example, when building a bath, the issue of thermal insulation of the walls from a high-temperature oven is of paramount importance. It is completely unacceptable to use asbestos for this purpose, since it is unsafe, tin panels, bricks and steel sheets are outdated materials. Magnesite can be called a cheaper analogue of minerite.

This natural material, which has undergone technological processing, serves in a high temperature regime, which is critical for analogs. Magnesite slabs are easy to cut and fasten, they do not emit harmful substances when heated. All indicators are similar to minerite, but fiber cement boards are leading as a more modern material. For example, fire-resistant panels made using Finnish LTM Flamma 9 mm technology are an excellent choice for a sauna device, in terms of safety, durability and aesthetics.

Of course, you can replace them with heat-intensive and affordable bricks. For thermal protection, fireclay and building bricks are equally suitable. But its disadvantage lies in the fact that you have to make a solution, and the structures from it are very heavy. In addition, the roof and ceiling cannot be protected with bricks. The minerite production technology was borrowed from the Finns by Russian and Japanese producers. Many people produce material on Finnish equipment.

Analogues are not inferior to the original in quality, and some are much more attractive in cost.

"Nichikha" - fiber cement siding from a quality Japanese brand. Differs from Flamma in textured brick-like structure and higher cost. In the European part of Russia, it is found much less often than in the vastness of the Far East. Flamma-minerite, accordingly, is more in demand in the west of the Russian Federation. In the NICHIHA product line, there are about 700 options for panels of complex designs, a selection of textures and colors to embody any ideas. At the same time, the panels do not require regular maintenance, are capable of self-cleaning and maintain an ideal look for a long time.

"Faspan Antiflame" is distinguished by its "ceremonial" appearance and persistent white color interspersed with mica. This sets it apart from the bulk of unattractive sheets in the construction market. Thanks to the beautiful texture, the buyer can save on finishing.

DSP (cement-bonded particle board) is a more budget option. Loses to minerite in external qualities. Fiber cement siding is a worthy competitor to the wooden counterpart, since the minimum service life of minerite is 50 years. Plates can be selected in size and shape, and most importantly - this one will cost less than using wooden materials.

The difference between the minerite slab and other building materials lies in its safe composition. At the same time, minerite is endowed with the ability to self-purify. Thanks to innovative production technologies, it does not emit harmful components when heated. Such insulation can be safely used for thermal insulation of steam rooms. Thanks to this, it will be possible to create a completely harmless microclimate in the room.

How to work with stoves?

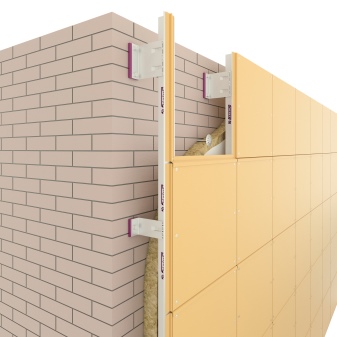

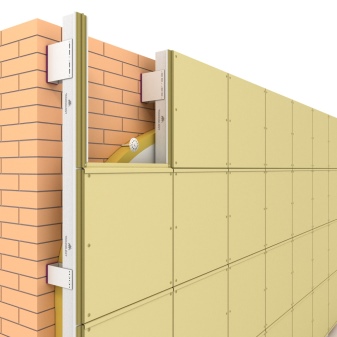

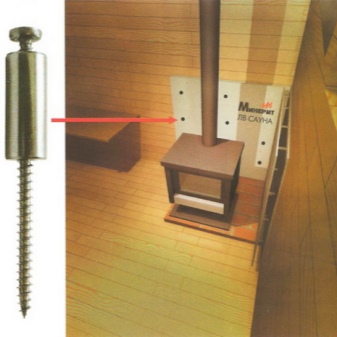

During construction, it is possible to install minerite panels in any season. Since the cement-based material is not an effective thermal insulator, when heated it transfers heat in sufficient quantity, which is risky for the timber structures located under it. Under fiber cement panels, it is necessary to lay basalt cardboard or mount it on ceramic sleeves, and sometimes put a second sheet through ceramic insulators.

Or mount the minerite on a metal profile frame filled with dense basalt wool.

When installing minerite slabs in a bath, the installation method depends on where the installation is being made. If the stove is located at a distance from the wall, it is allowed to fix the stove directly to the wall. If the stove is adjacent to the wall, you will have to mount two plates at once. Moreover, one should be screwed onto the wall itself, and the next should be fixed on the previous one, while maintaining a certain gap.

When installing minerite, to prevent breakage, it is necessary to make holes-grooves for fasteners. In addition, a small gap must be left between the floor and the bottom edge of the slab. This is important for the free circulation of air masses. To ensure the distance between the slabs, ceramic inserts or fragments of minerite slabs are laid. This is especially true when cladding of buildings that continue to shrink. In this case, over time, the inserts are removed, and the fasteners are tightened.

How to cut and drill?

Most men will be able to cut fiber cement siding on their own, but the task will not be an easy one. Despite the fact that the board is quite simple to handle, its structure is rather fragile, so you need to proceed with caution. Cutting the slab into fragments at home is done with an ordinary hacksaw. You will need a fine-toothed tool to ensure the cut is free from chipping or chipping.

The second method is to cut the siding with mechanical shears. This tool is powered by high air pressure. The principle of their work is similar to that of ordinary scissors. You can cut the slab with a knife, similar to how you would when working with drywall. The difference is that instead of a regular minerite knife, you need a carbide blade.

Carbide inserts are also suitable for cutting fiber cement boards. You will need dust protection for your mouth and eyes. Fiber cement boards are conveniently cut with a diamond-edged blade. The saw is considered the most efficient device for cutting slabs of this type. When working, it is important not to neglect the protection for the health safety of the installer. There will be too much dust.

For cutting the thickest minerite slabs, a circular saw equipped with a dust collector is suitable.

It is more convenient to cut the blade on the smooth side. With the help of a marker, a line is outlined, several times along its contour is drawn with a carbide knife. Then you have to lift the fiber cement slab and slightly press on the notch from the side opposite to the cut. When the plate bends in half, you need to make a series of cuts along the bend so that one of the pieces separates from the other. In such a simple way, you can cut such a plate yourself.

To summarize: for cutting sheets of minerite, an ordinary hacksaw will work, but if you have to cut a large volume, then you will need a power saw or hand scissors. Getting started, you need to understand that the scale of the cut is determined by the size of the blade, well, and you should not save money on working tools and your own protection.

Installation tips

Plates are usually mounted horizontally, preferring denser and thicker products with better thermal and acoustic insulation. Installation of facade panels does not present any particular difficulties. Primarily, the bearing profile is mounted on the walls in two directions - horizontally and vertically. In the process of fixing, it is necessary to provide for gaps based on thermal expansion. The value of such a gap should be in the range of 6 mm by 3 m of fiber cement sheet.

Specially designed self-tapping screws are used for fasteners. When they are screwed in, the hardware makes a hole with a larger diameter than its own section. Mounting the minerite directly on a wooden wall is unacceptable, since the material transmits the infrared radiation of the oven, heating up and risking a fire. Minerite must be fastened with a ventilation gap, or a heater should be laid under it, for example, basalt cardboard. As a base, you can build a parallel metal frame. Which installation method to choose is determined by the distance to the oven.

The comment was sent successfully.