All about brands of expanded clay concrete

A type of lightweight concrete made using different fractions of fired clay with a particle size of 5 to 40 mm as a filler is called expanded clay concrete. It has good thermal insulation properties, increased reliability and safety.

Strength marking

The quality and weight proportions of the constituents included in the concrete determine the main characteristics of expanded clay concrete: strength, thermal conductivity and water absorption, resistance to freezing and reaction to the effects of biological and aggressive environments... Specifications and requirements for concrete blocks for masonry are set out in GOST 6133, for concrete mixtures - in GOST 25820.

The main indicators for assessing the quality of blocks or concrete are strength indicators, denoted by the letter M, and density, denoted by the letter D. Their values depend on the ratio of the materials included in the mixture. But they are not always the same. When using expanded clay of different density, strength indicators also differ. For the manufacture of full-bodied expanded clay blocks, fillers are taken with a particle size not exceeding 10 mm. In the production of hollow products, fillers up to 20 mm in size are used. To obtain more durable concrete, fine fractions are used as a filler - river and quartz sand.

Strength index is the ability of a material to resist destruction under a load applied to a given material. The highest load at which the material breaks down is called the tensile strength. The number next to the strength designation will show at what maximum pressure the block will fail. The higher the number, the stronger the blocks. Depending on the withstand compressive load, such grades of expanded clay concrete are distinguished:

-

M25, M35, M50 - lightweight expanded clay concrete, used for the construction of internal walls and filling voids in frame construction, the construction of small structures such as sheds, toilets, one-story residential buildings;

-

M75, M100 - are used for pouring loaded screeds, building garages, removing the basement of a high building, erecting cottages up to 2.5 floors high;

-

M150 - suitable for the manufacture of blocks for masonry, including load-bearing structures;

-

M200 - suitable for the formation of blocks for masonry, the use of which is possible for horizontal slabs with a low load;

-

M250 - it is used when pouring strip foundations, building stairs, pouring sites;

-

M300 - used in the construction of bridge ceilings and highways.

The strength of expanded clay concrete blocks depends on the quality of all the components included in the blocks: cement, water, sand, expanded clay. Even the use of low-quality water, including unknown impurities, can lead to a change in the specified properties of expanded clay concrete. If the characteristics of the finished product do not meet the requirements of GOST for expanded clay concrete or blocks, such products will be considered falsified.

Other brands

There are several more ways to classify expanded clay concrete. One of them is based on the characteristic of the size of the granules used for filling. Let's consider all the options.

Dense concrete has quartz or river sand in the form of a filler and an increased content of a binder component. The sizes of grains of sand do not exceed 5 mm, the bulk density of such concrete is 2000 kg / m3. and higher.It is mainly used for foundations and load-bearing structures.

Large-porous expanded clay concrete (sandless) contains clay granules, the size of which is 20 mm, and such concrete is designated IN 20... The bulk density of concrete is reduced to 1800 kg / m3. It is used for forming wall blocks and creating monolithic structures.

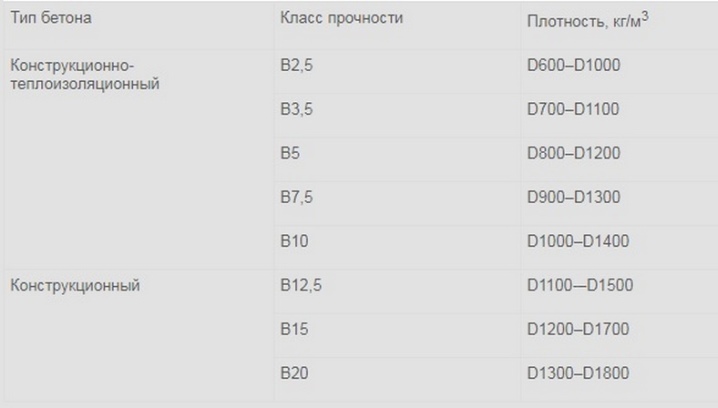

Porous expanded clay concrete contains fractions of clay granules, the size of which ranges from 5 to 20 mm. It is divided into three types.

-

Structural. The size of the granules is about 15 mm, designated as B15. Bulk density ranges from 1500 to 1800 kg / m3. It is used in the construction of load-bearing structures.

-

Structural and heat-insulating... For the mixture, take a granule size of about 10 mm, denoted B10. Bulk density ranges from 800 to 1200 kg / m3. Used for block forming.

- Heat insulating... Contains granules from 5 mm in size; bulk density decreases and ranges from 600 to 800 kg / m3.

By frost resistance

An essential indicator for characterizing the quality of expanded clay concrete. This is the ability of concrete, after it is filled with moisture, to freeze (lower the ambient temperature below zero degrees Celsius) and subsequent thawing when the temperature rises without changing the strength index. Frost resistance is indicated by the letter F, and the number next to the letter indicates the number of possible freezing and defrosting cycles. This characteristic is very important for countries with cold climates. Russia is geographically located in risk zones, and the frost resistance indicator will be one of the most important in its assessment.

By density

This indicator characterizes the amount of foamed clay, which was introduced into the composition of concrete, weight in 1 m3, and is denoted by the letter D. Indicators range from 350 to 2000 kilograms:

-

expanded clay low density concretes from 350 to 600 kg / m3 (D500, D600) are used for thermal insulation;

-

average density - from 700 to 1200 kg / m3 (D800, D1000) - for thermal insulation, foundations, wall masonry, block molding;

-

high density - from 1200 to 1800 kg / m3 (D1400, D1600) - for the construction of load-bearing structures, walls and floors.

By water resistance

An important indicator indicating the degree of moisture absorption without the risk of structural failure. According to GOST, expanded clay concrete must have an indicator of at least 0.8.

Selection Tips

In order for the future structure to serve for a long time, to be warm, not to accumulate dampness and not to collapse under the influence of adverse natural influences, it is imperative to obtain a full description of the grade of concrete or blocks that will be used in construction.

.

For pouring the foundation, concrete of increased strength is needed - the M250 brand is suitable. For the floor, it is better to use brands that have thermal insulation properties. In this case, the M75 or M100 brand is suitable. For overlapping in a one-story building, it is worth using the M200 brand.

If you do not know the full characteristics of concrete, be sure to consult with a specialist.

The comment was sent successfully.