All about crushed stone fractions

This article describes in detail everything you need to know about crushed stone fractions, including 5-20 and 40-70 mm. It is characterized what other factions are. The weight of crushed stone of fine and other fractions in 1 m3 is described, crushed stone of a large size is presented, and the nuances of the choice of this material are considered.

What it is?

Fractional crushed stone is usually understood as a material that is produced by crushing solid rocks. Such a product is used in a wide variety of areas of human activity. As for the fraction, this is just the most typical size of the mineral grain. It is traditionally measured in millimeters. Bulk materials are characterized by a fairly high strength and resistance to negative air temperatures.

The size of the fraction primarily affects the area of application of crushed stone. The service life of the structure is determined from its correct choice.

And also the fractional composition of the material affects the strength of the products. The assortment of any supplier includes crushed stone of various sizes. When choosing, it is recommended to consult with specialists.

What are the fractions of different rubble?

Different types of crushed stone also have different dimensions of stone fragments. Their application also depends on it.

Granite

The smallest type of crushed stone obtained from granite is a product of 0-5 mm. It is often used to:

-

fill up the sites being prepared for construction;

-

produce a solution;

-

lay paving slabs and similar materials.

Strangely enough, no one produces crushed stone of this size. It is just a by-product of the main production. In the process of industrial sorting, special machines are used - the so-called screens. The main obtained material goes to the conveyor, but the screening passes through the cells and forms heaps of various sizes.

Although it does not look very impressive in comparison with other types, this does not particularly affect the strength.

Fraction from 0 to 10 mm is the so-called crushed stone-sand mixture. Its excellent drainage performance and comfortable cost testify in favor of it. Crushed stone of a larger fraction - from 5 to 10 mm - also has quite good parameters. Its price suits the vast majority of people. Such material can be in demand not only for the production of concrete mixtures, but also in the arrangement of industrial complexes, in the formation of massive parts of structures.

Granite crushed stone 5-20 mm in size is the optimal solution for the arrangement of foundations. In fact, it turns out to be a combination of a couple of different factions. The material is mechanically strong and perfectly resists cold weather. Crushed stone 5-20 mm allows you to fill the pavement. Its strength also guarantees excellent properties for the formation of aerodrome pavements.

Crushed stone from 20 to 40 mm is in demand for:

-

casting foundations for multi-storey buildings;

-

asphalting areas for parking cars;

-

formation of tram lines;

-

decorating artificial reservoirs (ponds);

-

landscape design of adjoining territories.

With dimensions from 4 to 7 cm, there is no doubt that the strength of the stones will be quite acceptable. Such products are suitable when a large volume of concrete is required. Suppliers are focusing on the applicability of such crushed stone in road construction and in the formation of large structures.

Consumers often choose a similar stone as well. The experience of application is quite positive.

Products from 7 to 12 cm are not just large blocks, they are fragments of stone, always characterized by an irregular geometric shape. Manufacturers point to increased resistance to moisture and severe hypothermia. Particularly large crushed stone must necessarily comply with GOST standards. It can be used in the creation of hydraulic structures - dams, dams. A serious stone is used to form a concrete foundation.

Rubble blocks are very strong. They are able to withstand even the load from a two-story stone or brick house. They are also bought to pave roads and trim plinths. It can also be used for facing fences. In some cases, large crushed granite is an excellent decorative solution.

Gravel

This type of crushed stone just slightly falls short of the "bar" set by granite. The main way to obtain it is by sieving the rock extracted from the quarries. It should be noted that gravel is much more accessible than granite mass. Relatively low costs allow you to purchase a large mass of nonmetallic materials in order to cast foundation structures or make concrete products. Fractions of gravel crushed stone from 3 to 10 mm are considered small stones with an average bulk density of 1480 kg per 1 m3.

Mechanical strength and resistance to cold are highly regarded by builders and landscape specialists. It is pleasant to touch such a stone. It is often used to cover garden paths that are pleasant to the touch. A similar property is appreciated when creating private beaches. You can fill up the territory with such gravel almost anywhere.

Crushed gravel from 5 to 20 mm is even more in demand in the construction industry. The comparatively low flakiness testifies in favor of such a product. It is approximately 7%. The indicator of bulk density according to the standard for products of this brand is 1370 kg per 1 m3.

The main areas of application are the production of reinforced concrete products and the formation of concrete mortar directly on construction sites.

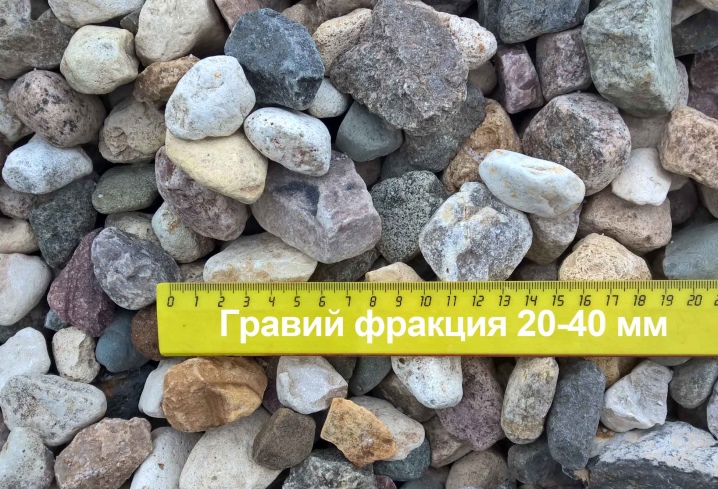

Crushed gravel from 20 to 40 mm weighs 1390 kg per 1 m3. The flakiness level is strictly 7%. The area of use is very wide. Even the formation of a "cushion" of public highways is allowed. Pouring a foundation or preparing a substrate for railway tracks will also not be difficult.

The gravel mass of fractional composition from 4 to 7 cm guarantees maximum strength and reliability of any foundations. You can no doubt prepare concrete floors, form embankments and create drainage systems. Weight in 1 m3, as in the previous case, is 1370 kg. Tamping the stone does not cause any problems. And this is a perfectly good solution for the vast majority of cases.

Limestone

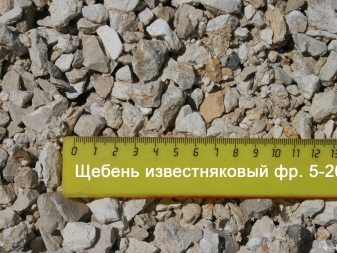

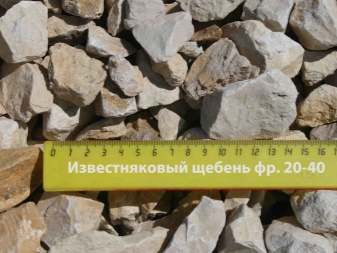

Such crushed stone is produced due to the fragmentation of calcite (or rather, rocks, the basis of which it is included). Such products do not achieve special strength. But limestone perfectly resists temperature fluctuations and is completely environmentally friendly. Thus, it is much less likely than granite to be a source of increased radioactivity. Like other stones, the limestone mass is carefully sorted at the main enterprises.

Large calcite crushed stone is in demand in road construction. Smaller fragments are most often purchased to obtain slabs and other reinforced concrete products. The limestone product is also readily bought for the decoration of landscape sites. Such products are used even in the most elite cottages.

Any experienced designer and even an ordinary master builder can offer many interesting ideas.

The number of cubes in a ton of granite material has long been calculated:

-

for fraction 5-20 mm - 0.68;

-

from 20 to 40 mm - 0.7194;

-

40-70 mm - 0.694.

In the case of crushed limestone, these indicators will be:

-

0,76923;

-

0,72992;

-

0.70921 m3.

Crushed stone 70-120 mm in size is very rare. This material is very expensive. Products with a size of 70-150 mm are even less common. Manufacturers often classify such goods as rubble stone. With their help:

-

build massive foundations;

-

retaining walls are prepared;

-

build capital walls and fences;

-

form decorative compositions.

In some cases, crushed limestone of 80-120 mm fraction is used. Like other types of this material, it meets all the requirements of GOST 8267-93.

The main areas of use are to increase the strength of the coastline and fill in gabions. Occasionally, such material is taken to be used in certain chemical reactions.

In large quantities, crushed stone is shipped by bulk or container methods; small quantities of this product are often supplied in bags of 30 kg, 60 kg.

Important characteristics of bag delivery:

-

meticulously prescribed parameters of the shipped products;

-

suitability for relatively small construction projects or repair work (excess material is not formed, or it is extremely small);

-

due to the accurately measured mass and volume, the carriage will be more streamlined;

-

inside a dense package, crushed stone can be transported by any type of transport, stored in almost any warehouse;

-

special marking makes it much easier to find the necessary products;

-

relatively high cost (which, however, is fully justified by other characteristics).

How to determine?

The crushed stone is supplied by the quarry. It is sorted by sifting through special sieves. A large enterprise can invite technologists or engineers to purchase. Analysis in the laboratory is carried out using a set of sieves. The larger the declared linear parameters of the samples, the greater the size of the sample.

So, for the study of gravel 0-5 and 5-10 mm, it is useful to take a sample of 5 kg. Anything larger than 40 mm is tested in 40 kg sets. Next, the material is dried to a constant moisture level.

A standardized, aligned set of sieves is then used. Wire gauge rings are used to measure crushed stone grains larger than 7 cm.

Nuances of choice

The choice of crushed stone of various fractions has a number of features. Granite or any other crushed stone can be used in a variety of cases, depending primarily on the dimensions.

5-20

A large house is built by adding granite with a size of 5 to 20 mm to the concrete. But for smaller structures, you can get by with a gravel mass. It will still be quite durable and will withstand the usual daily stress. Importantly, crushed limestone should be considered only as a last resort, since it is the least strong.

The material of such a fraction is indeed universal. You can safely choose it for a pillow under the paving slabs. It can even be used for decorating swimming pools. Decorating flower beds and slides is recommended. Two more possibilities: arrangement of sports grounds and visual separation of different zones.

20-40

Rough crushed stone of this size adheres very well to other materials in the composition of the concrete mixture. And also if you pour this mass with concrete, you will get a very strong mass that will not have weak zones and voids inside.

The wear resistance is higher than that of other dimensional positions.

It is possible to provide 300 freezing cycles and subsequent warming up to positive temperatures. Flakiness can vary from 5 to 23%.

40-70

It is practically a versatile building material. It is useful for the construction of a wide range of structures. Often 40-70 mm crushed stone is chosen for the foundation of the house. The same material is used for the decorative and practical arrangement of home gardens. Finally, it can be taken for the road, for example, for an inter-block passage or access roads to a dacha, to a suburban area.

70-150

This material has a highly specialized application.It may well be taken to prepare for the construction of road and even railways, it is so strong and stable. The construction costs of such serious objects are noticeably reduced in comparison with the use of universal mass categories, which are better left for household construction or for garden paths in the country. If 70-150 mm crushed stone is chosen for the construction of buildings, then we are talking exclusively about industrial and service facilities. Only in some cases can they purchase it for the construction of apartment buildings and foundations for them (if this is directly provided for by the project).

For drainage, a stone with a size of at least 2 cm is used. Fraction 0-5 mm will be instantly washed out with water. The product of the 5-20 mm category is more stable, but it is very expensive, and is mainly used in other areas of construction, therefore it is impractical to create drainage systems based on it. Most often, crushed stone 2-4 cm in size is used. For the blind area of houses and other buildings, crushed stone of a combined composition (fraction 20-40 mm, mixed with other options) is usually used - it copes well with the main range of tasks.

The comment was sent successfully.