Epoxy enamel: properties and applications

The range of varieties of paints and varnishes is very extensive today. Each type of such mixture has its own purpose and unique characteristics. So, epoxy enamel, the property and application of which will be discussed below, is in the greatest demand among other varieties of enamel paints.

Peculiarities

The main features and distinctive features of epoxy enamel are:

- Identity in technical characteristics with epoxy resins, because it is on their basis that this paint and varnish is made.

- High waterproofing qualities. Using this type of enamel, you can forever forget about such a problem as poor-quality waterproofing of any surfaces.

- They are suitable for painting almost any surface, such as wood, metal, concrete and even plastic.

The presence of such unique features influenced the widespread popularization of this paint and varnish product.

Advantages and disadvantages

High demand for enamel made on the basis of epoxy resin, her merits also had a great influence:

- Epoxy paintwork provides reliable protection against various acids, gases and alkaline solutions, remaining in the form of a film on the painted surface.

- The high level of adhesion provides a reliable, uniform coating of working surfaces made of any materials and tight adhesion to them.

- Epoxy enamel is not adversely affected by any kind of solvents and other petroleum products. Therefore, it is widely used in the automotive industry.

- After painting with epoxy enamel, any surface becomes protected from rust, pathogenic fungi and bacteria, as well as the negative effects of water.

- In most cases, epoxy enamel can be applied even in one layer. This will be enough for all-round protection of the product.

- Painting any surfaces with epoxy enamel can significantly extend their service life.

This paint and varnish composition has its own disadvantages:

- There is a poor level of protection against the negative effects of ultraviolet rays.

- When painting surfaces that are very hot, the paint quickly turns yellow.

- The average drying time is 24 hours.

- Thorough cleaning of the work surface is required before using epoxy enamel.

- It is imperative to observe the temperature regime during operation.

- Epoxy enamel should only be used in well ventilated areas.

There are still more advantages to such a coating than disadvantages, and the advantages are more significant. Therefore, the popularity of such enamel is increasing every year.

Composition and properties

Today there are several varieties of epoxy enamel, each of which has unique properties:

- VDEP R-270 Is a two-component white enamel protected from the effects of water compounds. Can be used indoors and outdoors, suitable for painting metal, concrete, plaster, wood and plasterboard surfaces. Reliably protects against mold, water and corrosion. Has a high level of safety, is considered one of the most fireproof, resistant to fading. The coating dries in two hours, requires two coats.Enamel is available not only in white, but also in black, beige, gray, brown and blue.

- EP-1236 specially designed for surface treatment of fiberglass, aluminum and metal. Belongs to the category of fire hazardous agents, is widely used in shipbuilding. It is characterized by fast drying, minimal consumption, rather pronounced aroma. Can be applied in three ways: roller or brush, conventional spray or airless spray.

- EP-773 - This is an enamel specially designed for painting metal surfaces that will subsequently come into contact with various alkalis at high temperatures. The average drying time is from two hours to a day, the surface of the coating is matte and smooth, the thickness of one layer is no more than 25 microns, the consumption of enamel is minimal.

- EP-5116 - black protective enamel designed for painting metal structures. It is widely used in the painting of oil tanks and pipelines. It has a high level of anti-corrosion protection, therefore, it is used to paint those metal structures that are most often in contact with water. After drying, it turns into a dense, glossy black film, characterized by a high drying rate.

- EP-140 Is a wear-resistant epoxy enamel that can only be used on previously primed surfaces. Suitable for painting concrete and metal structures, has a high level of fire safety. They are characterized by low consumption, high drying speed. Comes on sale in various colors. Forms a dense film on the painted surface that protects against rust, moisture, acids and high temperatures.

Each of the varieties of this paintwork can be used not only in industrial but also in domestic conditions. It is very important for its selection and operation to strictly follow the instructions and recommendations of the manufacturer.

Application

Having made the decision to use epoxy enamel, it is necessary to choose its type depending on the material of the work surface. You should choose either a universal paint and varnish product, or a specialized one, for example, for concrete or metal.

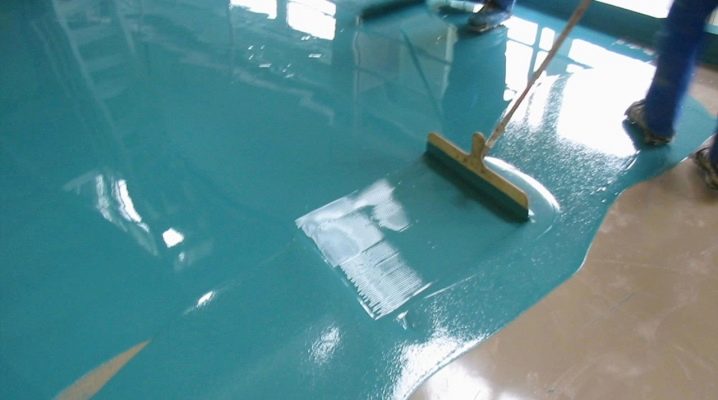

You can apply this product of various types as with a brush or roller., and using a special spray gun. The specific application method must be selected based on the area of the working surface, its location and the tools available at hand.

Preparation

The use of any kind of epoxy enamel begins with the preparation of the work surface. First, you need to remove all debris and dirt from it, the remnants of the past paint and varnish coating. If the surface is too greasy, then it must be degreased.

The next stage of work is priming. A particularly careful approach to the matter requires the priming of concrete coatings. By itself, concrete is quite porous, so the greatest attention should be paid to leveling its surface. The primer must be allowed to dry completely before applying the enamel to it.

Preparatory work also includes the preparation of the paint and varnish material itself. It must be mixed thoroughly to make sure it is uniform in consistency.

If the manufacturer's instructions for the product indicate the need for additional use of a solvent or hardener, then you must choose these products of the same brand. This is the only way to get really high-quality epoxy enamel suitable for further use. In advance, you need to make sure that all the tools necessary for the work are at hand.

Application methods

After completing all the preparatory work, you can proceed to the direct painting of the surfaces with epoxy paint based on the resins of the same name.

The procedure can take place in different ways:

- Painting with a brush or roller is the easiest and most affordable application method. But it is worth remembering that when choosing them, the paint consumption will inevitably be large. From a store container, pour a small amount of thoroughly mixed enamel into a smaller container or into a special roller tray.

The brush should be dipped into the product no more than halfway, shaking off excess enamel into the container.

The roller must be evenly impregnated with paint from all sides, but so that its excess does not run down to the floor. Movements should be gentle and slow, each new portion of the enamel must be applied end-to-end and in the same direction as the previous one. This staining technique requires at least two coats of enamel.

- Epoxy enamel can be applied with a special spray gun or airless spray gun. In this case, the liquid must be poured into the tank and further use the device in accordance with its instructions.

It is very important when applying multi-layer enamel to give the previous layer enough time to dry. The second and all subsequent layers are allowed to be applied 23 hours after the application of the first, but no later than 24 hours.

Safety regulations

Epoxy enamel belongs to the category of toxic agents. It has a rather strong chemical odor, and if it comes into contact with the skin, it can cause burns and an allergic reaction.

It is very important during work to strictly observe all safety requirements:

- The room must be well ventilated.

- It is better to use a respirator or mask as additional protection.

- It is necessary to choose the right clothes - it should completely cover all parts of the body, special gloves should be put on your hands.

- Use only wooden spatulas to stir the enamel.

- It is necessary to store and use the paint only under the conditions indicated by the manufacturer on the container.

Compliance with these simple, but very important rules will allow you to paint any surfaces with high quality and protect them for a long time from various negative influences.

See the video below for how to cover the bathtub with enamel.

The comment was sent successfully.