Heat-resistant enamel Certa: features and specifications

If we often use ordinary paints, then this cannot be said about heat-resistant enamels. Heat-resistant paint is intended for painting non-ferrous and ferrous metals, the material can have a combined composition. This type of dye protects metal surfaces and other types of coatings from high temperatures and aggressive environments.

What it is?

Ordinary paints cannot boast of heat resistance, so there is an increased demand for enamels from the Finnish companies Tikkurila, High Heat Black Paint, English manufacturers Rustins or Russian products Certa, which have high technical characteristics.

Heat-resistant Certa enamels are intended for painting metal surfaces, equipment, heating mains, oil and gas pipelines, furnaces and other surfaces.

The products have the necessary technical characteristics, confirmed by quality certificates.

Comparing with the composition of ordinary paint, which is used during repair work, it will be more complicated for heat-resistant analogs due to the larger number of components. The basis of heat-resistant paints contains a special suspension consisting of silicone varnish in a solvent with the addition of a filler and pigment. Heat-resistant paints are resistant to high humidity. This type of enamel can withstand temperatures from -50 degrees to +650 degrees Celsius.

Range

Popular paints from Russian manufacturers have found their application in many industries. Most often they are used in the chemical industry and mechanical engineering, they cover parts of furnaces and heating devices with them.

This type of paint has a certain specificity:

- contains a toxic solvent;

- before starting work, the surface is prepared;

- dry the Certa enamel at high temperatures.

It should be borne in mind that under industrial conditions Certa dries for 45-50 minutes., in home use without toxic accelerators, this time will not be enough. After painting, installation or transportation of equipment should be carried out only after three days. When painting metal parts, apply 2-3 cross layers.

Such a surface dries for at least two days, the temperature should be 18-22 degrees.

The most popular is heat-resistant paint for metal. Certa up to 900 degrees... Pigment is responsible for the color saturation of paintwork materials, more often you can find white or black enamel, but you can find other shades if you need to maintain a certain color range.

The most commonly used paint is black, semi-gloss black, silvery gray and graphite. Other colors are also chosen, among them yellow, copper, red, brown, blue, blue and green. In addition, unique novelties have appeared - gold and copper colors.

This paint will protect the material from corrosion, fire and moisture. Anti-corrosion paint is easy to apply, it is applied to metal, concrete and cement surfaces, after painting it dries within half an hour. After drying, the enamel forms a uniform film without wrinkles and irregularities. If the paint is applied to a weld or other hard-to-reach places, they are painted with a brush, passing several times over this area.

Paintwork materials are produced in different modifications, nickel, chromium or aluminum in powder can be added there. The company "Spectrum" produces Certa enamel in packages of 400 and 800 gramsand 520 ml aerosols for coating rough cast iron, forged and cast steel surfaces. After testing with paint, the coating has been confirmed to have a shelf life of up to 25 years.

You should pay attention to the novelty - this is enamel Certa patina, which is used to decorate metal products. Patina allows you to give products an aged effect.

It is used to decorate a fireplace, decorative grates and fences, barbecues, barbecues and other surfaces.

When applying patina to a metal surface, you should:

- stir the paint;

- dip the brush;

- grind excess paint;

- lightly touching with a brush, you should go over the selected areas without overlapping the previous layer.

How to use it correctly?

To prepare the surface for painting, it should be cleaned of dirt, rust, old paint, oil or grease. Mechanical or manual cleaning can be carried out. Surface treatment is carried out to grades St 3 or SA2-SA2.5. The letters St indicate that it is cleaned manually or mechanically, using a brush. Before cleaning, all rust should be scrubbed from the surfaces, the residues of oil products and dirt should be removed. After all contaminants have been removed, dedusting is carried out.

Blast cleaning is indicated by the letters SA. The SA2-SA2.5 grade assumes a very thorough cleaning of the surface. During the inspection, there should be no residues of oils, rust, paint or other contaminants.

After the surface is completely cleaned, it should be degreased with a solvent; for this, "Solvent" or "Xylene" may be suitable. Degrease the surface before work. You should not keep the product after processing without degreasing for more than six hours outdoors and more than a day indoors.

Before starting work with paint, check the surface, it should not be dirty or wet.

Preparatory stage

After opening the jar, stir the enamel thoroughly until the sediment disappears and wait ten minutes until the bubbles disappear. You can measure the viscosity of enamel with a special device VZ-246 viscometer, it is designed to determine the conditional indicator, that is, the expiration time of paintwork materials. Using "Xylene" or "Solvent", you can dilute the paint to the desired consistency, but not more than 30%. At the end of the work, the jar is tightly closed and left for storage.

When working with solvents, it is important to know that they are quite toxic, therefore it is not recommended to apply Certa enamel inside the living area.

Coloration

The paint is applied to the surface with a roller or brush. It should be applied in a thin layer, it depends on how well the organosilicon film and metal adhere.

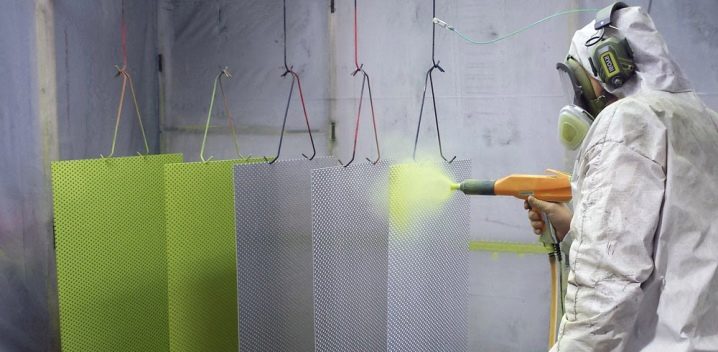

A more even coating can be achieved with a spray bottle or aerosol can.

When using Certa spray paint in a can, a very even coating is obtained, but many toxic substances get into the air. It is better to use this option for painting small items such as a brazier, barbecue or a muffler. It is important to carry out work in the open air, using protective equipment against toxic substances.

Many heat-resistant materials do not require pretreatment. The consumption of paintwork materials will depend on the conditions in which it is used. When painting the walls of the chimney, two layers of enamel should be applied; when painting braziers or barbecues, one is enough. On a brick or plaster surface, 2-3 thick layers are applied.

Safety requirements

When working with Certa enamel, it should be borne in mind that it contains aromatic solvents ("Xylene" and "Solvent"), which, if used incorrectly, can be harmful to human health.

When working with paintwork materials, you should adhere to safety rules.

- Apply the enamel outdoors or in well-ventilated areas.

- When painting, workers must have rubber gloves and a protective paste, it is imperative to wear a gas and dust respirator.

- Enamel is classified as a flammable liquid, so it is important to adhere to fire safety rules. There must be fire extinguishers at the work site, smoking is prohibited on the site.

- In case of fire, you need to be able to use means for extinguishing the fire, there must be water, sand, etc. on the object.

Storage

The shelf life of Certa paints at temperatures from -60 to +40 degrees Celsius is 18 months. These types of paints are stored in a tightly closed jar in places where there is no direct sun exposure.

You can learn how to paint the oven with Certa heat-resistant enamel from the video below.

The comment was sent successfully.