Heat-resistant enamel: types and nuances of choice

There are times when you have to work with non-standard surfaces. They can be hot or quickly heat up. For such work, you cannot use ordinary paint. The optimal solution is heat-resistant enamel.

What it is?

Heat resistant enamel is very different from other types of paints and their constituents. The composition of heat-resistant paints includes organosilicon varnish, and it already contains pigment compositions. Thanks to this, they can be not only black and white, but also in other shades that can suit any metal. Special fillers expand the range with different shades for non-ferrous metals, for example, for painting steel and cast iron.

Enamel gives the surface strength and durability, which is important for covering lids or fasteners. With constant sharp changes in temperature, the base should not change its shape.

Also, one of the main functions of heat-resistant enamels is heat protection of surfaces that have already been painted. All this happens thanks to the aluminum powder that is included in the paint. It works as a kind of reflector, which prevents the penetration of thermal radiation. Liquefied gas tanks, metal-type covers, gas pipelines and similar structures and parts are treated with similar compositions. Such a simple black heat-resistant enamel can withstand temperatures of six hundred degrees Celsius.

Peculiarities

Heat-resistant enamel has its own unique features:

- additional type of insulation;

- anti-corrosion properties;

- good chemical resistance;

- good plasticity.

The main feature of heat-resistant paint is exposure to different temperatures, while it does not change color and can "work" with any type of surface, this is its main technical characteristic.

Additional insulation is very important, especially when it comes to metal surfaces. Thanks to the enamel, there is no connection of static electricity, and no friction between surfaces. That is, the paint will not lose its plasticity under any physical, chemical and electrical influences.

Enamel, which is used for high temperatures, has excellent rust protection properties.

Heat-resistant enamel is also good for rooms where work with various components will be carried out. After complete drying, the paint will no longer be subject to any changes. The enamel perfectly tolerates various temperatures, does not change its shape due to its plasticity, and does not burst.

Advantages and disadvantages

pros

- The main advantages of heat-resistant enamels are comfortable and convenient processes for painting any surfaces and a high percentage of protection from various external and internal indicators.

- Fast surface preparation for possible further work. Sometimes there are cases when it is necessary to remove the old coating on the surface, and loose rust is found under it, which must be removed. This is done with a mechanical tool, and because of which traces remain, and as a result, irregularities. And then it is necessary to turn to these types of work in order to remove the areas of corrosion that were previously.

With the help of enamel, there will be no need for this. She will be able to smooth out all the corners and at the same time paint evenly.

- Excellent protective properties when applied.It is the enamel that is the component that includes high-quality, quick-drying alkyd-urethane varnishes that can dry quickly. Because of them, the coating becomes much stronger, more resistant to rapid abrasion, external and internal factors.

- There are other positives that make heat resistant enamel the best choice for heavy-duty work. The service life of this product is 5 years.

Minuses

Among the shortcomings, a feature such as a pricing policy is sometimes singled out. Among all brands, enamel is sometimes found at a high price, but nevertheless, thanks to the rather large assortment, you can choose a good brand at the best price.

Views

All paints that are used today for painting surfaces that can withstand high temperatures, are divided into three groups.

- by packing methods;

- shelf life;

- and application methods.

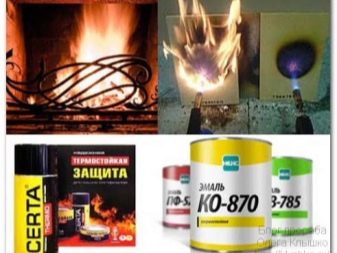

The choice of heat-resistant enamel depends on the purpose for which you are purchasing it., and what surface you will cover. Today there are even spray paint samples. The capacity of these cans is 0.5 liters. If you need to purchase a larger volume, it is best to take samples that are sold in cans, buckets or 40 kg barrels. To paint one square meter, you need about 230-260 grams of paint.

For seven months (the shortest shelf life) from the date of production, the paint retains all its properties. According to the standard, manufacturers must indicate the final date of sale on the product packaging. For the easiest application, aerosol-type paints are suitable, in such a situation it will not be necessary to purchase any additional tools, but this option is not suitable for painting a large area.

For painting large areas, it will be more economical to purchase cans and apply enamel with a brush or roller, only choose a roller with an average length.

If the paint has a good flowing consistency, then it is possible to paint with a pneumatic spray gun working in conjunction with a compressor. This type of painting is suitable for slabs, you can also use spray painting with a spray can.

Regardless of the method of application, stability and quality are completely preserved. Also, you need to understand that when using an aerosol or spray gun, the consumption per square meter will be slightly higher than when working with a roller.

Views

- Stainless steel aerosol - This is a paint of anti-corrosion type, sold in cans for painting metal surfaces. Such alkyd enamel consists of high-quality components that dry quickly, therefore they are excellent for construction and various decorative work, for household use.

You can also use it to paint scratches, chips and metal tiles. A similar paint is used to paint hard-to-reach places. On the surface, the paint looks glossy with a slight metallic sheen. Well suited for all types of work, even for a gas stove.

- Enamel KO - 8104 - used for painting asbestos-cement surfaces, which consist of metal and concrete. It can be used both for interior work and for an open area (outdoors). This type of paint is excellent for corrosion protection of tanks, pipelines, chimneys and other equipment. An analogue of such paint is grade 8101. In addition, analogs such as thermal 811,814,8111 can also be used.

- Anti-corrosion enamel is needed to protect against corrosion and painting decorative parts, they can be clean, and already painted, and even covered with rust. This type of enamel is perfect for any surface: steel, cast iron and various non-ferrous metals. These can be fences, gates, construction-type structures, rural equipment, metal cabinets, windows, doors, wood. You can use celsite.

Homemade tank sprayers can also be used for spraying.

Packing and colors

Packing can be different, everything will depend, what type of paint will you choose:

- spray can - 0.5 liters;

- can - from 5 liters;

- bucket - from 10 -15 to 40 liters.

The composition of the paint will depend on the temperature at which it can be used. The main component that is in any paint composition is organosilicon varnish.

Other types are also distinguished:

- epoxy group;

- alkyd group;

- ethyl silicate and epoxy ester;

- silicone;

- paint using composites.

The colors are mainly black and white, there are collections where a large selection of different shades is presented.

How to choose?

First you need to understand what kind of enamel is needed.

According to the temperature regime, they are divided into three groups:

- heat resistant;

- heat resistant;

- fireproof.

Fire retardant and fire retardant paints are two completely different compositions. The main goal of permanent paints is to make a fixed type film that can block air access.

Paints that can withstand high temperatures include those that retain their appearance at 600 degrees Celsius. Similar products can be used to paint stoves, baths or machine parts. If the temperature heats up to 800 degrees Celsius, then it is necessary to choose a paint from the heat-resistant group. It is also a good choice for rusty surfaces.

Refractory paint is required for surfaces that are close to fire. They will be able to perfectly protect the surface from external factors. But it is necessary to understand that such paint costs a lot of money, and it is often purchased by large companies for their work.

To save some money, you can purchase high temperature paints. They are perfect for any work conditions where the temperature does not exceed two hundred degrees Celsius. Similar paint is also used to cover brick seams on ovens.

Famous manufacturers and reviews

- VIXEN Is an alkyd enamel that dries quickly. The enamel contains special lightfast pigments that do not fade during staining under the influence of various light sources. On the surface, the enamel forms a good glossy finish with excellent gloss.

VIXEN is a versatile paint that has a large palette of different colors, so choosing exactly the shade that you need is not difficult. This brand has a double covering layer.

The paint has excellent weather-resistant qualities and adhesion properties to the painted surface. It adapts well to weather conditions on the territory of the Russian Federation.

On average, one square meter goes from 170 to 310 ml, the lighter the paint, the more consumption will be. This is due to the fact that you need to produce several balls of paint. In total, it is recommended to apply three coats of balls, regardless of the color of the paint. The enamel is dried for ten to fifteen minutes.

- DALI - an enamel created to work with metal technology, which is constantly working on the basis of high temperature. The enamel can withstand 600 degrees Celsius.

Can be applied to steel and cast iron surfaces, chimneys, ovens, machine systems, barbecue brushes or sprayers. The recommended number of layers is three. Large palette of colors.

It is forbidden to use enamel to dilute gasoline or kerosene. One liter of paint is used for seven square meters.

- Novbytkhim - paint, which is used to cover various surfaces: glass, concrete, brick. The enamel will be able to withstand from - 50 degrees to 600 degrees Celsius.

Just two colors:

- Gray;

- black.

It is recommended to apply in two to three layers. One square meter takes no more than 250 ml.

For homemade heat-resistant paint, see the next video.

The comment was sent successfully.