Description of 36M I-beams and their application

I-beams - in fact, these are "Tavras" installed opposite to each other, and not "backs", as is the case when making a cruciform pattern. It's like an I-shaped profile with crossbars, which can be placed on any of them - or put on one side.

Advantages and disadvantages

The I-beam partly resembles a rail, only not with a shortened upper longitudinal strip, as a rule, rounded from the sides, but with equal upper and lower crossbars. It is easy to put (and fix) it, it allows you to organize a monorail transport line. The advantages of an I-beam of any size are listed below.

- Service life is not less long - in comparison with other types of rolled products: simple tee, rail, round, square, plate (plate), etc.

- With the help of an I-beam, they can be covered very long spans in width.

- An I-beam, like a rail, is a common tee, an angle, round and square bars, easy to install and maintain, and reliable. With proper care, the I-beam structure will last for a long time - decades.

The disadvantage of the I-beam is that the weight of the product is almost twice as large as compared to the usual T-shaped profile. To reduce it, one has to be content with I-beams that are smaller in cross-sectional dimensions. However, then the margin of safety and reliability will suffer, although the I-beam does not bend, but, like a channel, holds the calculated weight of the overlying components and structures quite reliably.

Features of production

Any steel used for the production of I-beams can be taken - even the compositions of grades St3, St4 or St5... Too low-carbon, as well as almost chromium-free compositions are not recommended - too soft and quickly rusting steel can soon demonstrate all its shortcomings. If, for example, I-beams were used between floors in a high-rise building, then inadequate quality is fraught with a lot of dangers, up to deflection and collapse. In the worst case, low-quality steel containing sulfur and phosphorus in the amount of more than 0.08% will simply crack. And although before finishing work, the beams are covered with several layers of primer and enamel in order to exclude the formation of rust, you should use steel of a grade that is not worse in terms of parameters than St3Sp.

Before the installation of I-beams, they recognize the payload and the own weight of the elements, calculate the length of the beams (with allowances inserted beyond the perimeter of the premises or floor), as well as the flight distance. The total load takes into account all building materials from which the floor is made. I-beams, including 36s, are released and normalized after casting. This is necessary to exclude possible loading stresses, and also helps to find out whether the casting technology of the steel required for making the beam elements is not violated. Tempering embrittlement testing is in progress.

If a manufacturing defect is revealed immediately, then the rejected steel is sent back to remelting - until it is brought to the desired condition.

Main characteristics

The weight of 1 meter of I-beam 36M, according to the assortment data, is 57.9 kg. Other characteristics correspond to the following values:

- cross-sectional area - 73.8 cm2;

- moment of inertia along the X axis - 15340;

- moment of resistance along the X axis - 852;

- radius of gyration along the X axis - 14.4 cm;

- static half-section moment - 493;

- moment of inertia along the Y axis - 518;

- moment of resistance along the Y axis - 79.7;

- radius of gyration along the Y axis - 2.65 cm.

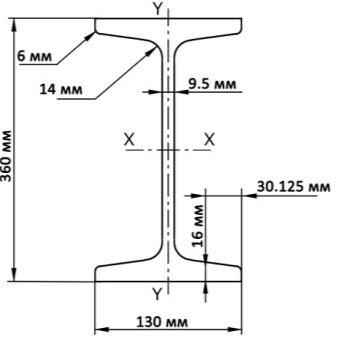

The height of the beam is 360 mm, the thickness of the central wall is 9.5 mm, the width of the lower and upper planks is 130 mm, the thickness of the same planks is variable: it starts from the edges from the 6 mm mark, and ends at the transition to the main (central) wall at an mark of 14 mm from the plane (edge) of the upper or lower end. Regardless of the "caliber", the I-beam is characterized by the following features. Elements with parallel edges can have medium, narrow, or wide side margins.

An inclined I-beam may not have a marking - in this case, it is considered as ordinary. A special purpose I-beam is marked with a marker "M", "C", while the side faces will be narrowed. Category "A" provides for increased accuracy of parameter values, "B" - an ordinary level of accuracy.

Ordinary elements are not used for outdoor installation, otherwise an additional requirement is imposed on them - resistance to corrosion.

In the simplest case, an I-beam is painted or varnished with waterproof and heat-resistant compounds.... For the construction of columns, a special I-beam of the "K" brand is used. It is used in places where the construction of simple reinforced concrete column stops is impossible or undesirable. The bearing capacity of such a subspecies of the I-beam component has an extensive margin of safety, capable of withstanding, for example, an overlap with a roof in an area where both of them hang over the entrance. This approach is used when simple reinforced concrete columns are not provided for in the project.

Finally, the I-beam "Ш" has extended lateral indents. Its purpose is a separate bearing support of a horizontal or vertical arrangement, which does not need external support against other elements and assemblies.

Application

First of all, I-beams are used for floors... They can withstand heavy loads of horizontal and vertical vectors of action. They are capable of covering spans of the order of 5 m. Steel does not burn - even in a fire, it may not significantly deform. Using an I-beam for slabs is much more practical than using other types of profiles, such as corner elements.

Choosing an I-beam, you can build a crane, erect a building or bridge crossing (or crossing). Due to the special H-shaped structure, it is possible to use this structural element as a load-bearing base for hydraulic structures.

The comment was sent successfully.