All About Metal I-Beams

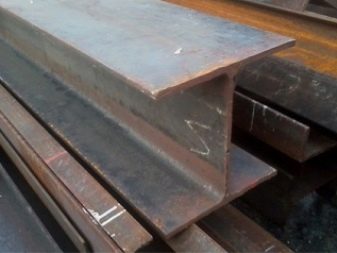

Metal I-beam - a special product of increased strength, the cross-section of which has the shape of the letter "H"... It is used in industrial and civil construction for the installation of floors and other structures.

Views

I-beam - a durable metal profile with the best performance characteristics... The rigidity of such a product is 30 times higher than that of square-section structures, and the strength is 7 times higher.

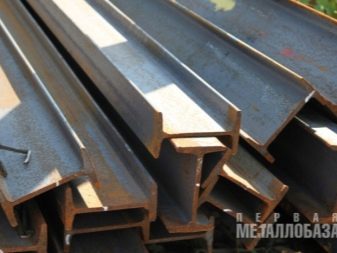

Today, I-beams are produced in different variations, expanding the functionality of the product and increasing its demand.

By the location of the edges of the shelves

In this category, I-beams are divided into:

- products with parallel flange edges, which include standard I-beams and column elements;

- rolled products with shelves, the edges of which are sloped.

The last group includes special beams that are in demand in the construction of unique buildings and structures. Such products are distinguished by improved performance characteristics, capable of withstanding high loads.

By production method

The second classification involves the division of beams according to the manufacturing method. Two types of I-beams are distinguished in this category.

- Welded... They are obtained by welding the wall and chords of the future structure.

- Hot rolled... For their production, special rolling machines are used.

The advantage of the first beams is that they allow you to experiment with dimensions due to the use of different types of rolled products: profile or sheet. The latter are made entirely of the same material and are considered unchanged along the entire length. In the construction of civil and industrial buildings, I-beams are used quite often. Therefore, the production of such products is one of the most demanded on the market. The most popular are beams made of low-alloy steel, which are additionally divided into normal and ordinary. Regulates the production and characteristics of I-beams GOST 380-2005, which indicates the required chemical composition of steel in the manufacture of beams.

If necessary, the parameters of the I-beam can be changed. This is possible with individual orders produced in small batches.

Dimensions and weight

Metal beams are characterized not only by improved properties, but also by their dimensions. The minimum number - the height - of the beams is 10 cm, the maximum reaches 100 cm. For example, beam 14B has a height of 140 mm, 30B - 300 mm, 20B - 200 mm. The minimum width of the shelves is 5.5 cm, the maximum reaches 40 cm. Products with shelves 16 and 30 mm wide are mainly common.

Manufacturers prefer to produce products with a length of 4 to 12 m, but if necessary, the indicator can be increased or decreased. For production, carbon or low-alloy steels with a high margin of safety are used. The advantage of this approach is the low cost of the material, which allows you to save on construction. The GOST prescribes the main parameters of I-beams, including the weight of 1 running meter. The characteristics are presented in the form of tables, and it will not be difficult to find the desired rolled products in the assortment.

Marking

The designation of I-beams is determined by their dimensions and is regulated by the requirements of GOST. It's worth starting with two numbers, which are at the very beginning of the marking. With their help, the height of the wall is indicated.Next are the alphabetic indices, through which it is possible to obtain information about the type of profile. Possible options:

- "B" - normal beams;

- "NS" - beams with wide flanges;

- "TO" - column elements.

If the letter "D" appears in the marking, then this product is from an additional series. And also in the I-beams there can be the designations "ДШ" and "ДБ". There are brands 20С1 and other options, the meaning of which can be found in the GOST.

Selection Tips

The choice of I-beams for the construction of a country house or industrial facility is equally complex and requires a number of factors to be taken into account.

- Dimensions (edit)... It is worthwhile to carry out calculations in advance of the cross-section of the I-beam in accordance with the loads that the structure will experience. Depending on the results obtained, it will also be possible to determine the number and total weight of the required profiles.

- Type of... In this case, it is recommended to pay attention to the type of shelves, dimensions and production method of the product. The listed parameters determine the strength characteristics of the finished rolled products, which can be found in GOST.

- Appointment... One of the important factors to consider. For example, when building a private house, you can give preference to simpler I-beams, since the loads will be small. Manufacturing buildings will require more complex configuration items.

- Price... There is no need to choose only expensive material. You can give preference to a manufacturer with favorable prices, and get a high quality beam.

To date, several companies are engaged in the manufacture of I-beams.

- NTMK... The enterprise is part of the international consortium Evraz Group and is a modern complex for the production of rolled metal, equipped with the equipment necessary for the manufacture of high-quality products.

- ZSMK... It is also a member of the consortium and has a high production capacity. The workshops are equipped with innovative installations, which made it possible to automate most of the processes and establish fast production of rolled products.

- LLC "LIZSK". A plant in Lipetsk, which is engaged in the production of welded I-beams. The high-tech line of the enterprise makes it possible to obtain up to 2 thousand tons of beams of various sizes in a short period of time.

- OOO TyazhMet. The company in Belarus produces welded I-beams and other types of rolled products with high performance characteristics. The enterprise is equipped with modern equipment.

And also distinguish the Tula plant for the production of high-quality rolled and welded products. The company is additionally engaged in painting and installing manufactured products.

Applications

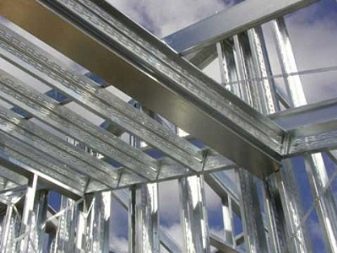

I-beams are in demand in the construction and industrial sectors. They are mainly used as:

- overlappings;

- columns;

- bridge metal structures;

- tracks for the crane in industrial buildings.

Steel beams are distinguished by the most advantageous shape, resistant to high loads and impacts. Products are found in almost all metal frame structures, as well as in public and industrial buildings. The assortment of produced beams is regulated by GOST and TU. High strength, reliability and ability not to deform under the influence of heavy loads makes rolled products in demand.

The comment was sent successfully.