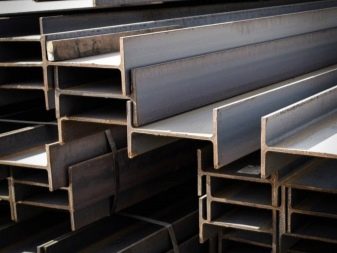

Range of I-beams

The I-beam provides a high level of reliability, along with a channel and a square or rectangular spigot. I-beams are the basis of floor slabs and column support structures, for example, in the subway.

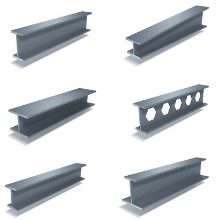

Views depending on the shape of the section

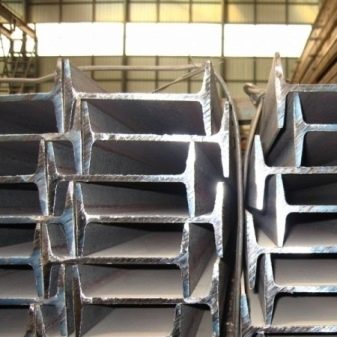

The assortment of I-beams differs depending on their design. These can be column elements, whose ends are made in the form of located at right angles to the main part of the beam, which is the basis of its length and cross-section. Conventional I-beams have an H-shaped profile with some truncation on each side, in which the side faces are directed from the T-flanges.

In contrast to the full-fledged H-shaped profile, which does not have lateral truncation, the width of the flanges of the I-beam is considered significantly reduced.

The I-beam itself resembles two T-shaped (T-shaped) elements, which are connected by sides where there are no shelf edges. The opposite type of I-beam - "cross" - resembles a "plus-shaped" or cross-shaped bearing element, from one of the T-bars of which the shelves are cut off, and the remaining strip is welded along the mid-shelf line longitudinally. The "cross" has less rigidity and bending strength than the H-shaped I-beam, since it cannot be placed on an even base without a 45-degree tilt. Rolled I-beams are subdivided into hot-rolled and cold-rolled. The first is widely used in the construction of buildings and structures - from a low-rise apartment building to a bridge.

The second is more used in decorative construction. For example, when erecting a symbolic monument to the fallen heroes or the culture of any of the peoples, erecting a memorial sign of a district or city, you can use both hot and cold rolled steel. Due to its almost mirror-like, ideally smooth surface, cold-rolled I-beams are used as an element of capital and decorative construction, arrangement of all kinds of objects. It does not require additional grinding, unlike a hot-rolled I-beam. Smaller I-beams, for example, with a main lintel width of less than a few centimeters, are used as frame elements for sofas, double beds and wardrobes. One or another kind of furniture item, reinforced with professional steel, has greater durability in terms of all kinds of deformation and overload effects.

Varieties according to the materials used

According to the materials used, the I-beam is supplied in the form of steel and aluminum elements. Steel and aluminum are characterized by extremely high cheapness, which allows these components to be mass-produced. Copper bronze or brass I-beams are very rare; these elements are used only as components of a custom interior or as non-load-bearing furniture inserts that play a decorative role. Compared to steel I-beams, non-ferrous metal I-beams have several times less strength. Aluminum, for example, breaks easily when bent. Both copper and aluminum bend easily, although copper I-beams can handle significantly more bends. Steel I-beams are most often made from steel St3sp - a quiet variety of steel 3."Calm" steels, in comparison with semi-calm and boiling ("restless"), differ in less porosity, which does not allow them to rust quickly: the rate of rusting in water is noticeably less than 1 mm per year for the thickness of the product.

Frost-resistant I-beams, which are less cold brittle in frosts of up to tens of degrees in terrestrial conditions, are capable of operating up to -150 degrees, since they are made of steel alloy 09G2S, which allows them to be used without compromising their properties even at the Pole of Relative Inaccessibility in Antarctica. This steel could also be used in full-scale rovers operating in Martian conditions at –110 Celsius - again, without loss of properties. A wooden I-beam, in contrast to a steel one, is used as a substitute for timber when arranging attic and ceiling ceilings.

Composite and metal-composite, plastic I-beams are more likely components of equipment and furniture, and even then auxiliary - they are not assigned a load-bearing role.

Assortment by parameters

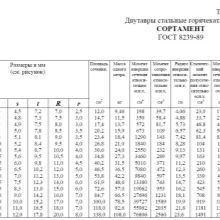

The dimensions of the beams take on their values in accordance with the following parameters.

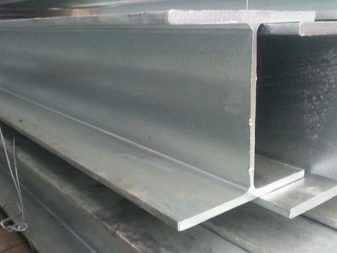

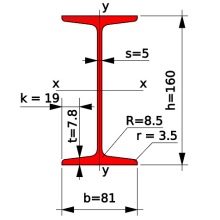

- Radius of rounding. Its value can vary in the range of 1-14 mm. The larger the beam, the higher its value. Rounding is a characteristic that informs about the smoothness of the transition between the main wall (lintel) and shelves (sidewalls).

- The width of the side shelves. An effective value is used, equal to the sum of the values of the width of the shelves on each of both sides of the longitudinal (shelf) end, on which the I-beam can be placed. As a result, he takes his position as if "standing". The thickness of the jumper is added to the obtained value. In practice, both the width of each shelves are used separately, and the total - outer - value of their width.

- Wall width, or height of the I-beam, Is a parameter describing the width of the lintel itself inside the element, excluding its shelves. But in practice, the value outside the element is often used - the total height, taking into account the thickness of the flanges of the I-beam, set "standing".

- Lintel thickness. With this value, the consumer does not have any additional questions to the manufacturer and sellers.

- Shelf thickness - the parameter is ambiguous: variable thickness, for example, at the edge and at the middle of the shelf, may differ by a millimeter or more.

- Slope angle of faces - I do not mean the physical bending of the shelves outward, but the location of the inner side due to the variable thickness. In this case, the outer sides of the shelf components remain parallel to each other.

- Type of black or non-ferrous metal alloy or non-ferrous metal. This parameter determines the flexibility, strength and elasticity, the hardness of the material from which the I-beam is made. The steel alloy requires a smaller wall thickness, since, in addition to hardness, it has a pronounced elasticity and toughness in comparison with non-ferrous metals.

- Segment length and cross-sectional area.

The last two parameters are used to calculate the volume of steel used for the production of elements and their weight. The weight characteristic is important when calculating the cost of delivery of a batch of I-beams from the nearest warehouse of the seller to the consumer.

Popular brands

The production of I-beams takes into account more than a hundred items, including Sh1, 35B1, 30B2, 25K1, 45M, 35SH1, 35B2, 30SH2, 30K1, 30K2, 25B2, 10B1, 16B1, 40SH2, 30M, 40B2, 45B1, 35K1, 14B1, 25K2 , 40K1, 12B1, 20K2, 18B1, 50SH1, 23B1, which are in the greatest demand. The number in the designation on the left is responsible for the width of the main wall in centimeters: for example, the 35B1 beam has a lintel height, respectively, 35 cm. The general rules for marking I-beams are determined by the standards GOST 26020-83 - according to it, the height of the steel I-beam is 10-100 cm.The width of the shelves, according to the same requirement, does not exceed 40 cm, but not less than 5.5 cm.

Marker "B" in the designation means an I-beam of the usual construction. Wide flange I-beams, respectively, are marked with the letter "Ш". Columns, in turn, are characterized by the letter "K" in the name cipher.The number "1" on the right, at the end of the designation, characterizes the nominal format for indicating the width of the wall, while "2" is responsible for the not entirely reliable indication of the width of the wall. For example, for 14B1 products, the real wall width is 137.5 mm, for 14B2 elements, the real correspondence of the indicator with its width of 140 mm.

The use of I-beams is differentiated by their standard sizes. For example, beams 14B-20B are used for ancillary single-storey construction, beam elements 21B-35B are used for interfloor floors in low-rise buildings. Beams 36B-50B are suitable for multi-storey buildings with more than three storeys, as well as one-storey high-ceilinged shopping and entertainment centers and supermarkets. Beams 51B-80B are suitable for the construction of interfloor and floor-basement ceilings in buildings up to several tens of floors. Beams 80B-100B are used in the construction of bridges for highways and railways, flyovers and other more grandiose structures, including multi-storey towers and spiers up to hundreds of meters high, which are unique structures of their kind.

The wider and thicker the beam, the more construction opportunities it provides. But I-beams are not only the prerogative of construction: some "carriage" I-beams, along with channel ones, are used in heavy machinery, for example, in the construction of tower cranes, as well as in the construction of cars and locomotives. I-beams are also used in machine-tool production: machine-tool building, especially conveyor, uses 20B-50B beams all the time.

Reinforced concrete-beam bridges serve as an excellent and very fixed support for the rail-and-sleep lattice of the railway - on sections of bridges, where, unlike completely overland stretches, a pebble embankment and other engineering solutions are not used that make already overloaded bridges heavier.

The comment was sent successfully.