Description of I-beams 40B1 and their application

I-beam 40B1, along with I-beams of other sizes, for example, 20B1, is T-profile with a total width of 40 cm. This is sufficient height to create a highly durable and highly stable base.

Advantages and disadvantages

Due to the use of low-carbon steels, the 40B1 I-beam is an element that can withstand a significant level of load. This means that the I-joint created with its help has a triple (or more) margin to withstand not only its own weight as a destabilizing load, but also the weight from building materials used as flooring, for example, boards, siding with water vapor barrier , reinforcement and poured concrete, etc.

Low-carbon medium-alloy steels slowly accumulate mechanical fatigue stresses, but, like any steel, they dampen vibrations and shocks well. Steel - alloys with so-called impact toughness, which, for example, aluminum and duralumin do not have. I-beam 40B1, like other T-elements, withstands millions of shock and vibration cycles before microcracking appears, ultimately leading to breakage of the brand.

An I-beam, like a single tee, channel and corners, weld well, drilled and cut on a milling or plasma laser machine... As welding, automatic and manual electric arc welding is used, as well as gas welding in an inert environment. Steel 3, as well as high-alloy steel alloys such as 09G2S, are subject to almost any mechanical treatment. If you follow the technology of this processing, for example, before welding, to clean the products to a shine, then the resulting joints will hold reliably for decades until a new developer or installer disassembles them in order to make significant changes.

There are also drawbacks to T-elements. Regardless of the size and weight of the element, whether it turns out to be 40B1 or any other, T-joints are more difficult to transport than, for example, channels and a square professional pipe. The presence of a special cross-section of the profile does not allow laying this type of rolled metal as compactly as possible: the shelves must be pushed into the voids formed by the distance (internal gap) between them.

This will require a lot of effort on the part of the movers during loading at the warehouse and unloading at the destination.

Specifications

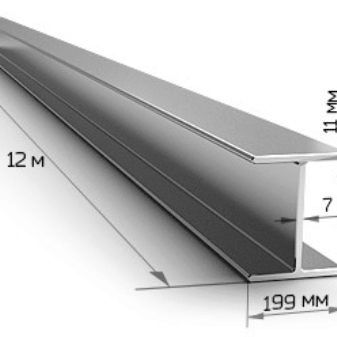

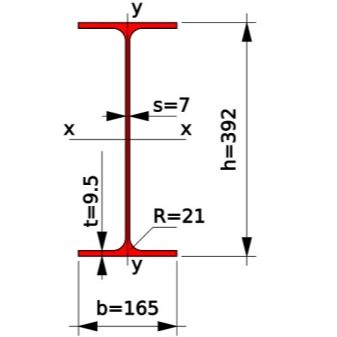

Before deciding on the field of application of the 40B1 I-beam, we will give the main characteristics of this rolled product, which are of paramount importance for the laying technicians, as well as the distributor of these products. The product is manufactured according to the standards of GOST 57837-2017 (updated Russian standards):

- real total width of rolled products - 396 mm;

- sidewall width - 199 mm;

- main wall thickness - 7 mm;

- sidewall thickness - 11 mm;

- radius of curvature of the wall and sidewalls from the inside - 16 mm;

- weight of 1 m of I-beam 40B1 - 61.96 kg;

- section length - 4, 6, 12, 18 or 24 m;

- step for taking into account the length of the element - 10 cm

- steel alloy - St3sp, St3gsp, 09G2S (S345);

- the height of the main wall without taking into account the rounding and thickness of the shelves - 372 mm;

- weight of a 12-meter I-beam 40B1 - 743 kg;

- density of steels - 7.85 g / cm3.

Steel St3 or S255 is replaced by the S245 grade. This alloy has characteristics similar to C255, which makes it easy to machine. The range is determined only by the grades of steel, the standard size for 40B1 is the only one.

Application

The scope of the 40B1 beam is construction. It is an important element in the floors and foundations of single and multi-storey buildings. The higher the number of storeys of the building being erected, regardless of its purpose (residential or work), the more requirements for the rigidity and vibration resistance of structures... Steel St3sp and its analogs are easily welded, drilled, sawn and turned: there are no special difficulties in the process of joining the 40B1 beams into a single whole. Beams 40B1 mean standard use of products without increasing accuracy classes. Bearing structures based on 40B1 are easily assembled, which ultimately allows them to be used immediately when installing flooring and insulation, for example, when building a shopping center or a supermarket.

Before installing the flooring elements on both sides of the beam, it is recommended to paint: St3 steel and compositions similar to it in terms of characteristics rust at any humidity... In addition to construction, the 40B1 beam is an indispensable element for the construction of frame-hull structures of wagon-trailer equipment, thanks to which the delivery of goods by land method is simplified and accelerated to the limit.

Welding and bolting make it easy, using mechanized equipment and tools, to mount a chassis (support) base for any type of transport, be it a car or a truck crane.

The comment was sent successfully.