Dowels for thermal insulation: types of fasteners and features of choice

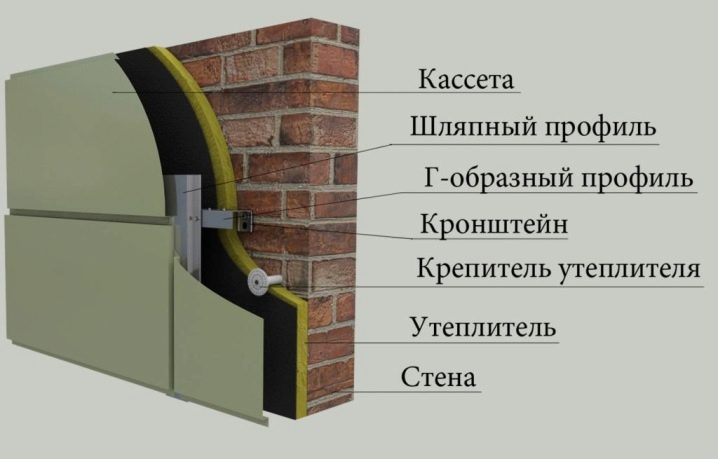

The performance of work on the insulation of the facade of the building involves the solution of the main task - the installation of thermal materials. For installation, you can use an adhesive solution, but when performing a large amount of work and to increase the reliability of the structure, it is better to use a special dowel-nail or disc dowel.

Peculiarities

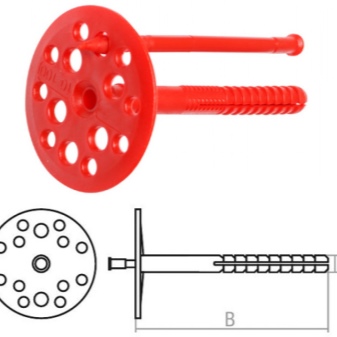

The disc dowel can be visually divided into three conventional parts - the head, the ordinary rod probe and the spacer zone. A distinctive feature of the plate dowel head is a width with a diameter of 45 to 100 mm. This constructive solution allows you to reliably fix the insulation to the facade of the building. The hat has a rough surface and is equipped with tapered technological holes to increase the adhesion to the insulation. Under the head there is an ordinary zone of the rod, ending with a spacer zone, which is responsible for fastening the entire thermal insulation system to the facade and consists of several sections. The length of the section depends on the dimensions of the disc dowel itself and averages 60 mm. The disc dowel also includes a spacer nail or screw that fixes the dowel by expanding the spacer zone.

Views

Disc dowels can be divided into the following types according to materials of manufacture, characteristics and field of application:

- with a plastic nail - used for fastening light structures, entirely made of nylon, low pressure polyethylene or polypropylene;

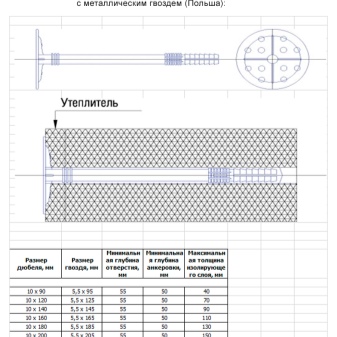

- with a metal rod - it contains a metal expansion nail, which significantly increases its reliability;

- with a metal rod and a thermal cover - in addition to the metal expansion nail, there is a thermal cover to reduce heat transfer;

- facade dowel with fiberglass rod - construction model, expansion nail made of high-strength fiberglass.

Based on the type of attachment, the following types can be additionally distinguished:

- dowels with a strong core - can be hammered in with a hammer, which significantly speeds up the installation process;

- dowels with raised heads - designed for installation only with a screwdriver or screwdriver.

Specifications

Each product unit from the list above has its own unique properties and each has its own positive and negative qualities. Before purchasing a sufficient amount of fastening material, you must familiarize yourself with the characteristics of each type of disc dowels:

- Dowel-shaped dowel with a plastic nail. It is made from nylon, low pressure polyethylene or polypropylene. In terms of their properties, these materials are virtually identical, so they should not affect the adoption of a positive decision when choosing fasteners. Since this fastening material is entirely made of plastic, it is very lightweight, which allows it to be used in any structure without worrying about the load on the load-bearing wall. But there is a downside to this - they should not be used to fasten heavy insulation, they simply will not withstand it.

The absence of metal in the composition of the spacer nail gives it additional advantages - resistance to moisture and poor thermal conductivity. The first advantage makes it immune to corrosion and extends its service life up to 50 years, and the second makes it possible to minimize heat loss.At the same time, during installation, extreme care must be taken when working with a plastic spacer nail. Possessing low stiffness, it has the unpleasant tendency to bend and break at the most inopportune moment.

- Disc dowel with metal nail. It differs from the previous model in that it uses a 6 mm thick galvanized steel metal nail as a fastening element. This significantly increases the strength and allows you to withstand the weight of any structure and use it when working with any kind of insulation. And unlike a plastic nail, a metal spacer nail won't break or bend. But this type of disc dowels also has disadvantages. A metal spacer nail conducts heat better than a plastic one and can create areas where the wall can freeze through, which will not happen with a dowel made entirely of plastic. The second drawback is corrosion. If the wall remains wet for most of the year, then the entire spacer nail will go through the unprotected head of rust, which will lead to the failure of the entire thermal insulation system.

- Dowel-shaped dowel with metal rod and thermal cover. This is an improved version of the previous fastener, designed to work in wet conditions. The main difference lies in the plastic plug, which is attached to the dowel head. It prevents moisture penetration and reduces heat outflow, so such fasteners can be considered more airtight. There are two versions - with a removable plug that you need to install yourself, and a plug installed at the factory. The second option is more convenient to use, because the plugs are rather small and are stored separately. It is quite easy to lose them during work.

- Facade dowel with fiberglass rod... This species has appeared on the market relatively recently. It is assembled from the following elements - a clamping part, a fiberglass rod, an anchor element with a spacer zone and an expansion washer, which is put on the clamping part to create an additional area for fixing the insulation. Thanks to the fiberglass rod, the dowel has high strength and low thermal conductivity. All these elements can be selected separately, guided only by the required dimensions.

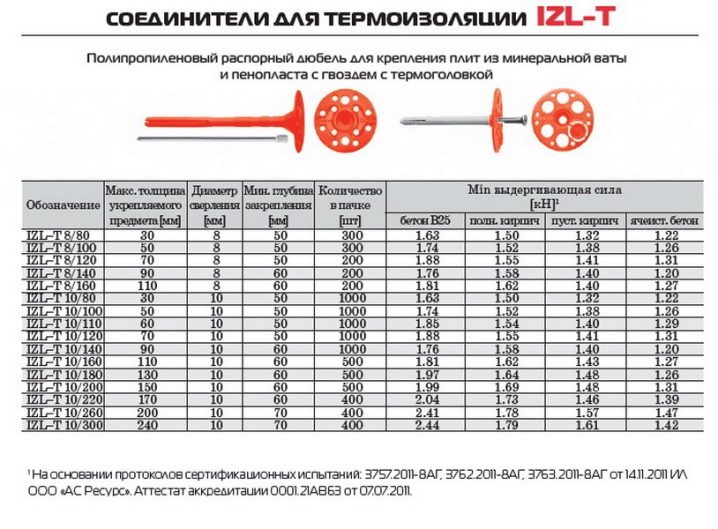

A certificate of quality for thermal insulation panels must be present. Today, species such as fungi and umbrella are often used. The mushroom can be screw, IZL-T and IZM.

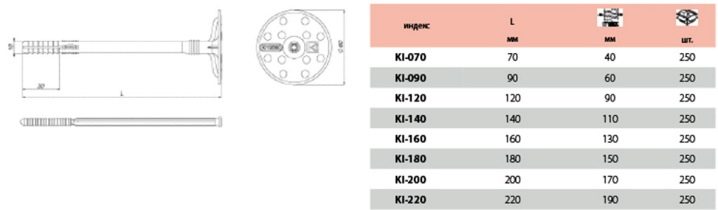

Dimensions (edit)

The dimensions of the elements of the disc dowels vary depending on the type, purpose and manufacturer. In GOSTs, the definition of a dowel-nail and a dish-shaped dowel is absent, therefore it is impossible to be tied to state standards. Therefore, below are the average dimensions broken down by type of fastener.

The disc dowel with a plastic nail has the following dimensions:

- the length of the plastic fasteners is from 70 to 395 mm;

- the diameter of the expansion nail is from 8 to 10 mm;

- diameter of the disc element - 60 mm;

- the thickness of the insulation for installation should vary from 30 to 170 mm;

The plate dowel with a metal nail has the following dimensions:

- the length of the plastic fasteners is from 90 to 300 mm, which are standard parameters;

- diameter of the disc element - 60 mm;

- the diameter of the metal expander rod (nail) - from 8 to 10 mm;

- the thickness of the insulation can be from 30 to 210 mm.

Manufacturers overview

Today, the leading manufacturers of disc dowels are enterprises in Russia, Poland and Germany. Taking into account the order of the President of the Russian Federation Vladimir Vladimirovich Putin "On the implementation of the import substitution program", it is worth paying attention to three domestic leading companies that produce disc dowels:

- Termoklip Is a trading and manufacturing company that represents in the markets of Russia and the CIS countries several series of disc dowels made of block polymer based on high molecular weight polyethylene. The metal elements are made of carbon steel with a resistant anti-corrosion coating. Some models are protected by an insulating cover.

- Isomax - this company produces 10 mm diameter disc dowels with a galvanized nail and the possibility of installing a thermal head. The metal nail is made of carbon steel with an electro-galvanized coating.

- Tech-Krep Is a Russian company that manufactures plastic disc dowels with several versions: with a plastic and metal nail, with and without a heat-insulating cover. Dowels are made from primary raw materials using a complex chemical composition. The metal nails are made of hot-dip galvanized steel.

How to calculate?

For reliable fastening of the insulation, first of all, it is necessary to correctly calculate the size of the dowel rod. For calculations, you must use the following formula:

L (bar length) = E + H + R + V, where:

- E - the length of the spacer segment of the dowel rod;

- H is the thickness of the insulation;

- R is the thickness of the adhesive solution (if necessary, gluing);

- V - deviation of the facade from the vertical plane.

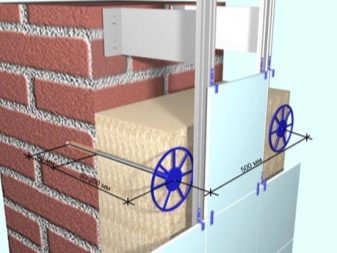

The number of dowels used for the installation of insulation directly depends on its weight. For example, penoplex can be reinforced with 4 dowels per 1 m², and for basalt wool you need from 6 pieces. The exact amount is calculated in the process of calculating the surface area of the thermal insulation to be insulated.

The formula for calculating the total consumption of fasteners is as follows:

W = S * Q, where:

- S is the total surface area;

- Q is the number of dowels per 1 m² of insulation.

An additional 6-8 pieces must be added to the final calculation in case of unforeseen expenses (loss or breakdown). When calculating the consumption, it should be additionally taken into account that, unlike walls, more fasteners go to the corners. Therefore, in addition, it is necessary to add another 10-15 pieces. The main costs of fasteners per square meter may be different. You can spend as much as 90 dowels, and 140, 160, 180 and even 200.

Application Tips

When choosing disc dowels, you should pay attention to some of the nuances:

- if the installation of penoplex takes place, then the choice should be stopped on varieties with a rough hat;

- it is worth paying increased attention to the quality of anti-corrosion treatment if there is a risk of precipitation entering the insulating structure;

- when insulating high-rise buildings, you should purchase the most expensive models of disc dowels with a metal spacer nail and a plastic thermal head, which protects the structure from moisture ingress;

- to the preferred performance characteristics, in addition to maintaining the total mass of the structure, its own weight and dimensions, and also the temperature range of operation should be added;

- in northern latitudes, under extreme weather conditions, it is undesirable to use a plastic disc dowel with a plastic spacer rod in the installation of an external insulation. The fact is that at extremely low temperatures and changes in humidity, there is a serious risk of cracking and further destruction of the entire thermal insulation system. In such a situation, preference should be given to a disc dowel with a metal rod and a thermal cover or a facade disc dowel with a fiberglass rod.

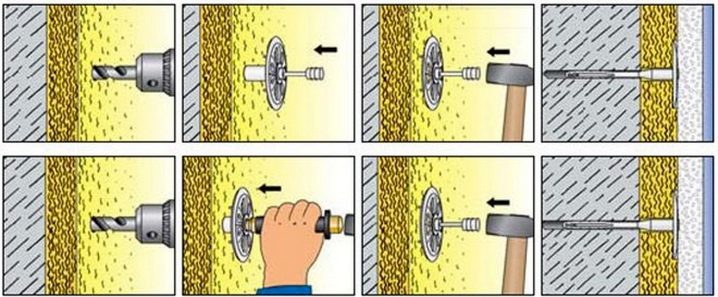

Disc dowels are used for the installation of insulation on the facades of industrial, commercial and residential premises. The installation process itself can be divided into the following stages:

- marking of the insulation installation area;

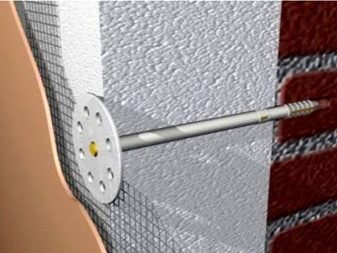

- drilling holes through the insulation;

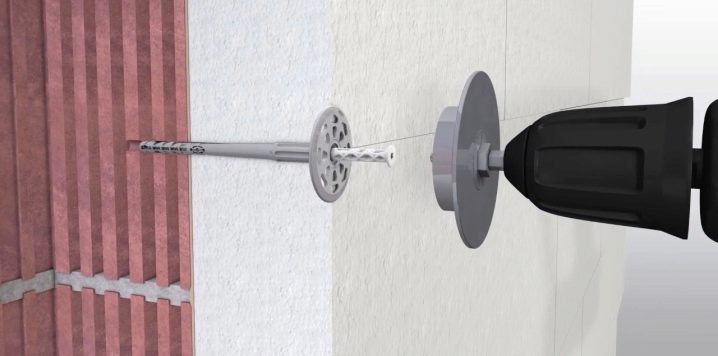

- installation of the dowel into the bore hole until the cap is completely drowned in the insulation;

- installation of a nail for spacer and hammer it to the required level.

It is worth dwelling in more detail on the technical aspects of the insulation procedure.

- Before starting work, you must prepare the original surface. For this, all depressions and bulges are removed until a flat surface is obtained. Then, the insulation is attached to the work surface using a special adhesive mixture. If the surface is fairly flat, a notched trowel can be used for shaping.

- So that the first row of insulation does not fall under the mass of the subsequent ones, a starting bar is attached to the lower part. Sheets will rest on it. Then, after the adhesive mixture has completely dried (about 2–3 days), the sheets are finally fastened with disc dowels. First, holes are made in the previously marked places using a perforator.

- It is imperative that the support points at which the fasteners will be made are at the joints of the sheets - this way it will be possible to prevent the appearance of additional holes for unwanted heat transfer, at the same time, at the end of the installation, the edges of the slabs will not be bent.

- Then, the heat-insulating material is stitched with a disc dowel to the base of the cap. The expansion nail is driven in such a way that the cap fits as tightly as possible to the thermal insulation material. It is important that the dowel goes into the base by at least 1.5 centimeters.

- Then, all joints must be carefully preserved with the help of thermo-reflective metallized tape. If there are gaps of more than 0.5 centimeters, then they can be blown out with construction foam. However, this procedure should be performed with extreme caution, as some types of foam can dissolve the polymer heat insulator.

- The disc dowels are attached only once. If you make a mistake in the calculations and pull the dowel out of the wall, it will collapse. To avoid this, it is necessary to take the preparation of the seat very seriously. Inside there should be no cracks, chips, sand, dust and other debris. The hole is drilled to the diameter of the selected fastener. The depth should be 0.5–1 cm more than the length of the selected element.

- After fixing the heat-insulating material, rather deep holes remain in it, which must be repaired with a paint spatula.

If you adhere to all these tips and the order of work, then the insulation of the facade will take a minimum amount of time, and the production process itself will be as productive as possible.

For information on how to properly attach thermal insulation to the walls using a dowel, see the next video.

The comment was sent successfully.