Foil insulation: varieties, properties and possibilities of use

Foil insulation belongs to the category of thermal insulation materials with a wide range of applications. Before buying, it is recommended to study the varieties, properties and possibilities of using each type of product.

Application

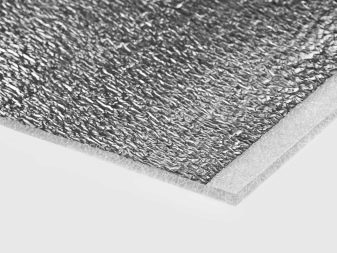

This material for thermal insulation belongs to the category of combined products. It is a layer with polyethylene foam and polished foil. By combining the two materials, high quality thermal insulation is provided for the building envelope.

Products with foil mineral wool can be used in different rooms. Depending on the purpose of the object, it is necessary to select the appropriate type. Insulation is suitable for almost any surface, but most often it is purchased for the following objects:

- Pipe sheathing. Operation for pipes of hot and cold water supply is allowed.

- Insulation of ventilation shafts and air ducts.

- Insulation of the canvas, arrangement inside the roof.

- Thermal insulation for walls from inside the house or outside.

- Laying a layer under linoleum.

Views

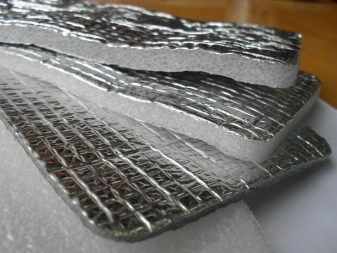

Depending on the purpose of the products, several types of insulation are produced. They differ in terms of the density of the used foil and the type of heat-insulating material.

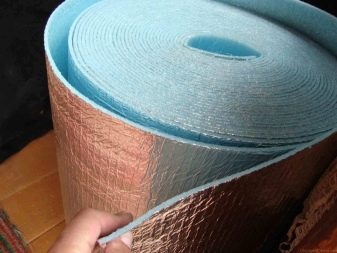

Penofol

Foil penofol (second name: polyethylene foam, izolon, folgoizol). These are roll products, which have a low price tag. In the role of insulation, polyethylene foam of a cross-linked or non-cross-linked type is used. The layer thickness is 3-8 mm, 10 mm. The foil layer is located on one or both sides. Self-adhesive base is allowed.

Some types of products have a reinforcing layer in which fiberglass is present. Moisture absorption rates are 0.35-0.7%. Water vapor permeability is about 0.001 mg / m * k.

The material is used to work with the underfloor heating system, for arranging a heat-insulating layer in the room, as well as for split systems. Also, the canvas can be used as a pipe insulation.

Minvata

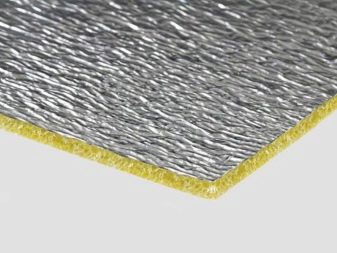

This material can be produced in rolls or in the form of slabs. Products with an aluminum coating help to increase thermal protection, as well as protect hygroscopic material from moisture.

Basalt is often used as a mineral insulation. It has increased moisture resistance and is characterized by a long service life. Such insulation can be used in various fields. It can often be found as insulation for chimney pipes, for arranging walls, ceilings, and roofs.

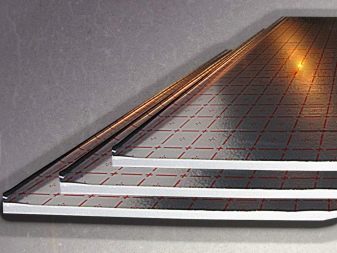

Styrofoam

This material is used for the underfloor heating system. On the inside of the product there is a marking, which is intended for laying the cable system. The density of the material is 30-50 kg / cubic meter. The thickness of the product reaches 3-5 mm. Insulation is produced in a roll 50 cm wide. Foil-clad foam is not intended for other applications.

Basalt heat insulator

The heat insulator is able to cope with aggressive conditions of use. The material does not lose its qualities in a temperature range from -200 to +700 degrees.It is used during the construction work of various structures.

Specifications

All types of material differ in a general list of technical characteristics:

- Resistant to temperature changes.

- Moisture resistance.

- High level of vapor permeability (value is 0.001 mg / m.h. Pa).

- High performance in terms of reflection of thermal radiation. The thermal conductivity is 0.037 W / m ° C.

- Foil insulation is a heat-resistant material.

- Adequate level of sound insulation (sound absorption reaches 68%).

- The foil provides reliable protection against the effects of solar and radon radiation. Also, aluminum insulation does not require additional treatment with chemical agents, which indicates the environmental safety of the material.

- According to the manufacturers, the products have a long service life, which reaches 95 years.

Advantages and disadvantages

Foil insulation has the following advantages:

- Thanks to the metal layer, the material does not corrode.

- The product is able to provide an auxiliary soundproofing layer in the room.

- Insulation helps to reduce heat loss.

- The productivity of the heating system is increased. This is achieved by reflecting thermal energy.

- The canvas allows you to save heating costs.

- Insulation with heat insulation prevents drafts.

- Wide area of use.

- A wide range of assortments, which differ in the type of insulation material and the thickness of the sheets.

- Resistant to moisture.

- Low weight and good elasticity.

- Ease of installation.

- There are no toxic compounds in the ingredient list. For this reason, the material is considered environmentally friendly.

- Affordable price range.

Also, the insulation has disadvantages:

- Due to the soft structure, it is impossible to use insulation under the finishing mixtures for construction work.

- If you use a product without an adhesive base, you will need to purchase special adhesives. This indicates additional costs.

- A small thickness of the interlayer is not able to provide a sufficient level of thermal protection. For this reason, the product is often supplemented with other insulation materials.

Installation features

During installation, you should familiarize yourself with some of the features of the process:

- The thickness of the insulation used to insulate the wall, ceiling or floor should not be less than 50 mm. Experts recommend using the same material for complex work. However, if the ceiling is insulated with a thicker canvas, this will not be considered a mistake, since the bulk of the thermal energy leaves through the ceiling. For this reason, special attention should be paid to the canvas.

- The properties of mineral wool are that it absorbs moisture. After getting wet, the material loses its insulating properties. At the same time, the insulation gives off moisture poorly, and in cold weather, wet particles can turn into pieces of ice.

- To prevent moisture crystallization, foil-clad insulation will need protection. The thin aluminum layer may have small holes or micro cracks that cannot be seen. At the same time, if there are even two barriers for vapor and moisture, vapor particles can still penetrate the thermal insulation. For this reason, experts recommend creating insulation layers in such a way that moisture can leave the cotton wool.

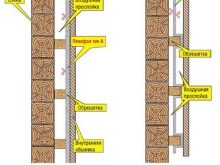

The order of the levels of the insulation cake:

- Finishes made from natural materials. Most users use wooden lining for these purposes.

- Vapor barrier film. It is a membrane that contributes to protection against moisture and vapors. Laying should be done end-to-end with the finishing material.

- Ventilated gap.It is an air gap that is formed by creating a crate.

- Insulation with foil for wall surfaces. Laying should be done in such a way that the reflected rays can return to the room to the main wall.

- Waterproofing layer. This is a membrane that will not allow moisture to pass through, but allows steam to pass through. Laying is done close to mineral wool.

- There must be an air gap between the foil and other surfaces. If you neglect this rule, the insulation material will not be able to reflect infrared rays.

The thermal insulation material should be located between the battens guides. For these purposes, you can use wooden blocks with a thickness that exceeds the thickness of the insulation. This quality allows you to provide a ventilation gap between the foil and the finishing material.

There should be a distance between the guides, which is 3 cm less than the width of the heat-insulating sheet. The waterproofing layer is fixed against the wall and fastened with staples. Since there is a difference between the width of the cotton wool and the cells in the crate, the insulation material shrinks tightly, without requiring auxiliary fixation. A vapor barrier is mounted on the crate. Finishing material should be laid on top of it.

Thermal insulation of the balcony

Insulation of a balcony or loggia is carried out using foil insulation with a base in the form of polyethylene. The polyethylene is foamed, after which aluminum foil is glued to it. The thickness of the foamed polyethylene can be up to 10 mm. The canvas acts not only as a reinforcement and a damper, but also is able to prevent heat losses.

Most users know this material as penofol. There is one-sided and two-sided material, the foil of which can have a smooth or corrugated surface. Products with auxiliary protection in the form of a polyethylene film are also produced. The layer is applied using lamination.

Thermal insulation of a balcony without auxiliary insulation is not effective and does not allow achieving the desired result. For this reason, penofol should be used in tandem with foam or cotton wool.

The easiest way to work with foam is using self-adhesive foam glue. Outwardly, it is similar to simple polyurethane foam and you can use a polyurethane gun to apply it.

Insulation is carried out according to the following scheme:

- The foam must be glued to the prepared base from the inside.

- Penofol is laid on a foam layer.

- On top, you should fix the wooden blocks that will be used for decoration.

- Then you need to sew up the resulting "pie" with any finishing material. You can use plaster, siding or block house.

- Laying of foam foam with an overlap is not allowed. The joints are glued with a special aluminum tape.

To insulate the floor, you will need to arrange the guides according to the level, and then place the foam between them. Penofol must be placed on the guides. Further, there are two ways of styling:

- the floor is installed directly on the foam foam layer;

- the second level of the lathing should be mounted, and then the floors should be laid.

Experts recommend using the second method, since when using the first method, the ventilation gap required to reflect the insulation cannot be obtained. If you exclude the arrangement of the ventilation gap, penofol is not needed either, since there will be no benefit from it.

Thermal insulation of pipes

Foil insulation for the pipeline is used during the arrangement of communications underground or by air.To reduce heat losses of pipes, foil insulation is used even in unheated rooms, which are located on the basement floors in suburban buildings.

No special guidance is required for installation, as the installation of foil insulation is easy. It is enough to put the shell on the desired area and in some places remove the protective coating from the adhesive layer, which is located at the ends of the longitudinal cuts

Due to the reflective surface, communications are provided with protection from solar radiation if the reflective shell is located only outside. If a reflective coating is present on the inside, it promotes heat transfer back to the pipe.

Foil insulation is used for interior decoration, and can also be used to isolate communications that are located on the street. Mineral wool, expanded polystyrene or foamed polyethylene are used as the basis for the heat-insulating material. Wool and foam insulation is used as a key insulation layer, and a reflective shell is used as an auxiliary barrier.

Bath protection

If you plan to insulate the bath, it is recommended to purchase roll materials. This is due to the fact that it is easier for an untrained person to work with rolls. For these purposes, you can use polyethylene foam or medium thickness mineral wool.

Most often, wooden buildings are insulated. Installation is started from the ceiling, going to the walls. The thermal insulation material with the floor foil is installed last. For work, you will also need parchment, which is glued to the ceiling, paired with mineral wool.

Fastening of foil insulation to the wall is carried out according to the following scheme:

- First of all, you need to create a wooden crate. Rolls fit into it. For fixing it is necessary to use glue.

- If the foil insulation is torn, the damaged area can be repaired with metal tape. Craftsmen advise using basalt wool with foil, which rarely breaks.

- Then you should attach the planks to the crate. They are further joined by a ceiling covering. The foil film is fixed with strips.

- If foil-clad basalt wool is not available, it can be replaced with another thermal insulation material with foil. The installation of products is carried out in the same way as the installation of cotton wool.

- The easiest way is to lay polyethylene foam. To install it, you just need to cut the roll into the necessary parts and carry out the headlining. Heat-resistant adhesive tape is applied to the seams.

- Installation of insulation on the surface of the walls occurs in a similar way. The difference is that you need to provide an overlap of five centimeters, which must be superimposed on the floor and ceiling. Thus, steam will not be able to leave the room. There should be a small gap between the inner wall and the foil layer.

- Hot air vapors rise upward, so the ceiling should be given special attention. Many users are laying basalt wool in two layers.

Outside the building

Insulation of wooden houses is best done from the inside, since such an event allows you to keep warm. However, if internal insulation is not possible, external cladding is allowed. For these purposes, it is necessary to purchase foil mineral wool with an average layer thickness.

To ensure quality work, you will need:

- adhesive agent;

- a gun for carrying out construction work;

- set of dowels;

- wind protection film;

- grinding brush.

Laying of foil insulation for exterior wall decoration is done as follows:

- Work begins with the equipment of a metal cornice, which is fixed with dowels.The cornice is required so that the mineral wool slabs are level.

- On the back of the basalt wool, you need to apply glue and press the slab to the wall surface. Plastic dowels can be used as an auxiliary fastening.

- Level the surface with a sanding brush.

- A windproof film is laid on top of the insulation.

- The process ends with priming and external finishing of the structure.

Also, exterior wall decoration can be done with penofol. It is distinguished by its easy installation and affordable price category. For these works, it is better to purchase perforated penofol. The product is able to protect the surface from getting wet.

When insulating a wooden house, you should use antiseptics for treating the walls. The corners of the structure need to be processed more carefully.

Warming with penofol consists of several steps:

- It is necessary to build a structure from rails. Sheets of penofol are further fixed on it.

- The joints should be masked with metal tape.

- If external cladding is being made, it is recommended to use an additional frame.

- Laying foil insulation outside is allowed only at positive temperatures and in dry weather

Internal wall insulation

With the help of penofol, walls can be insulated outside and inside. Installation of products is accessible even to a beginner. The layer thickness is 5 mm. If the building is located in a region with harsh winters, an additional insulation layer will be required for insulation. Experts recommend using foil-clad mineral wool in rolls.

Insulation laying consists of the following steps:

- cutting the material should be carried out in such a way that the length of the product coincides with the dimensions of the walls;

- penofol is attached to the wall with a stapler;

- after the installation of penofol is completed, the joints should be sealed with tape;

- GKL is laid on top of the insulation layer.

You can replace penofol with foil-clad basalt insulation. However, its installation is accompanied by additional conveniences due to the need to equip an auxiliary frame.

For roofing

For work with the roof, basalt slabs with foil are used.

Step-by-step guide to roof insulation:

- All cracks on the roof must be repaired. For this, you can use polyurethane foam or tow.

- Then a vapor barrier should be created. Glassine, fastened with a stapler, is suitable for him.

- The next layer is waterproofing. Since basalt wool with wood construction can start to rot, it is necessary to use polyethylene.

- Foil insulation is laid last. It will require a special formwork. The installation of the material is carried out by a spur with subsequent fixation with a cord.

See the next video for more details.

The comment was sent successfully.