House insulation from foam blocks

A private house should be cozy, warm and as comfortable as possible. In recent years, the construction of houses from foam blocks has become widespread. Insulation gives a comfortable temperature inside the house, regardless of external weather conditions, and also allows you to save heating costs.

Important features

Foam blocks have been developed specifically for the construction of buildings with single-layer walls. They are characterized by low thermal conductivity, which is several times better than the corresponding parameter of silicate bricks. This is why many homeowners question the need for additional insulation. And in fact - due to the increased thermal insulation properties of foam blocks, in warm countries, such structures do not need additional thermal protection.

However, in the conditions of Russian winters with low temperatures, it would be correct to think over a system of additional insulation of the building. In addition, do not forget that foam blocks are a rather fragile material. When exposed to unfavorable atmospheric factors, they quickly absorb moisture and freeze through, which leads to the destruction of the material from the inside and a reduction in the service life of the building. To prevent such troubles, facade insulation is used.

There are a number of cases when insulation of foam blocks should be mandatory:

- for walls less than 37.5 cm thick, in the case when the masonry provides for an impressive thickness of the seams - cold bridges are created through them;

- if high-density blocks of grades D500 and more are used in construction;

- when the width of the blocks is less than 30 cm;

- if the foam concrete fills the load-bearing frames;

- in case of builders' mistakes, when cement mortar was used instead of a special adhesive in the masonry.

In all other cases, thermal insulation is used at will. Even if you are building a country house that you do not plan to use in the winter, you will still need insulation.

In this case, the external wall decoration allows you to neutralize the adverse effects of water. In addition, the use of insulation allows you to significantly reduce heating costs.

Insulate inside or outside?

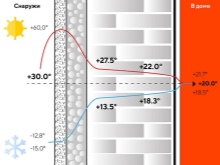

The best and best insulation option is outside. It is possible to insulate from the inside, but the following nuances must be taken into account:

- Foam blocks will freeze without external insulation. And the water that gets into the foam block will destroy it when it freezes. Also, each material is designed for a certain number of freeze-thaw cycles.

- Ceilings (floor, ceiling) will contact cold foam blocks and transfer heat through them to the street.

- When choosing an internal insulation, you need to make sure of its environmental safety, since it can emit harmful substances in a living room.

- When designing walls, there is a rule that the vapor permeability of the material that is outside should be greater than that of the material inside. This is necessary so that humidity from the room can escape through the walls to the outside. When the insulation is located indoors, this rule is violated. Because of this, the humidity in the house may be elevated, mold may appear in the space between the insulation and the wall.

All these troubles can be avoided by insulating the house from the outside.

Insulation methods outside

There are several types of thermal insulation materials that are suitable for effectively protecting foam block buildings from cold and adverse weather conditions.

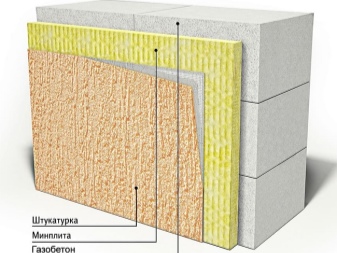

Mineral wool

There are two types of mineral wool: glass wool and basalt wool (or stone wool). The main component of glass wool is broken glass. Basalt wool has the main component of rocks, therefore it is also called stone wool. Both types of mineral wool have good vapor permeability - 0.3. Also, the advantages include incombustibility.

When choosing mineral wool, pay attention to its density. If the density is low, then over time, the insulation will lose its shape and this will affect its protective properties. It is advisable to use cotton wool with a density of 80 kg / m3. It is also necessary to follow the installation rules so that the cotton wool does not shrink and does not change its shape.

Mineral wool consists of the smallest fibers, which, when installed, can get on the hands, face and other parts of the body and cause irritation. Therefore, the installation of this type of insulation is allowed only with the use of personal protective equipment (respirator, heavy gloves, goggles, clothing that covers all parts of the body). Glass wool and stone wool should be carefully covered, since the smallest particles of insulation begin to spray under the influence of the wind.

Please note that the material has the ability to absorb and accumulate moisture. Therefore, it is not laid down during rain and snowfall. Basalt wool is the most widespread in the construction of private houses and summer cottages.

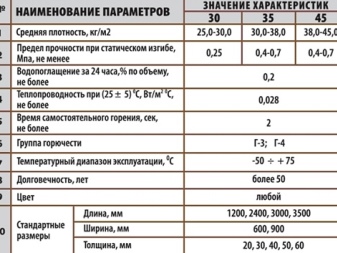

Expanded polystyrene and extruded polystyrene foam

Expanded polystyrene (PPS) is chosen for its affordable cost and frost resistance. The thermal conductivity of this material is lower than that of mineral wool. This means that it retains heat better. The vapor permeability of the material is low - 0.03, which means that excess moisture will not leave the living space and can lead to mold. Also, the disadvantages of expanded polystyrene include its flammability.

Extruded polystyrene foam (EPS), in comparison with other heaters, has unique uses. Due to the fact that EPS has a uniform cellular structure, it is able to withstand huge loads.

For example, it can be used to insulate walls in soil, foundations. EPPS has a low vapor permeability - 0.013. It is a durable and waterproof material that is resistant to mold and mildew. EPS is slightly more expensive than other types of insulation. The most widespread is the material of the PENOPLEX manufacturer.

General rules for installing insulation

Regardless of which material is chosen, you will need to protect it from ultraviolet radiation and moisture. The insulation process includes several steps:

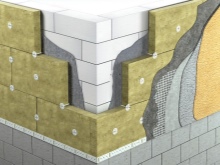

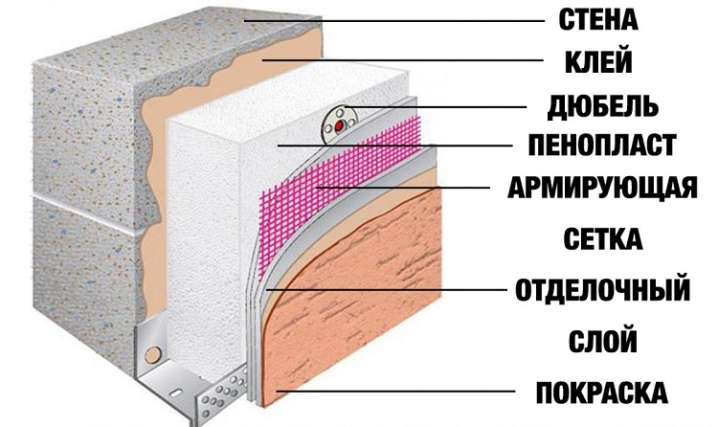

- First, the walls are thoroughly cleaned of dirt, dust, grease stains. If necessary, they are aligned.

- The prepared surface is covered with a layer of soil. This will prevent the glue from absorbing into the wall and thus create additional waterproofing for the foam blocks.

- Due to the fragility of foam blocks, it is undesirable to use metal fasteners. The optimal solution would be a special adhesive for facade work.

- Steel guides are fixed at the bottom of the wall. Moreover, their width should be equal to the thickness of the insulation.

- Next, you need to apply glue around the entire perimeter of the plate and slightly in the center, and then press it tightly against the wall and hold for a few seconds. Work is carried out in the direction from the bottom up.

- After installing the heat-insulating material, the reinforcing mesh should be placed on the glue.

- At the final stage, the facade is finished - the walls are sheathed with clapboard or covered with plaster.

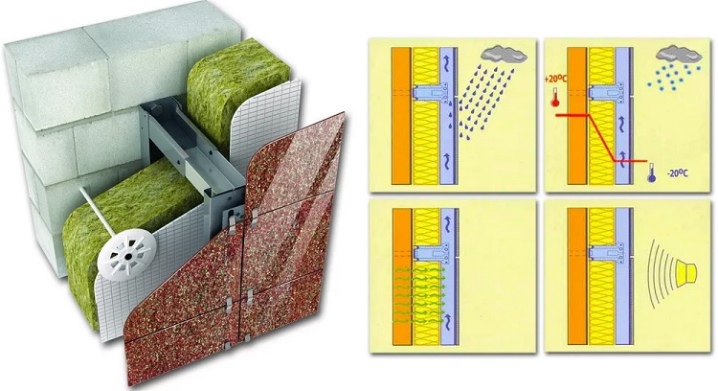

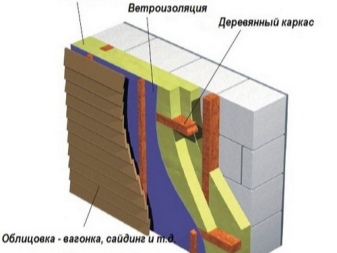

The technique is slightly different in the case when you plan to lay a heat-shielding layer under the siding. First, it is necessary to fix a waterproofing film on the wall, then fix the vertical guides and insert mineral wool between them. After that, it remains only to close the insulation layer with a vapor barrier film, make a crate for the ventilation gap and sheathe the walls.

When building houses from a foam block, thermal panels are very popular. They are a type of foam with a cement finish. Thermal panels are on sale in the widest range, with their color scheme and texture they imitate any facing materials.

Such plates are connected to each other through special fasteners. They are fixed to the walls with dowels, the fixation points are additionally fastened with cement mortar. Thermal panels can be installed at any time.

The most important thing is to keep the walls flat and dry.

How to insulate the inside?

If for some reason you still plan to make insulation inside the house, then for mineral wool you should definitely make the protection with a vapor barrier. If there is no vapor barrier on the border with foam concrete, the insulation will get wet and lose its properties. In this case, the moisture generated in the house will not be able to escape through the walls, so you will need to make good ventilation.

Foam plastic is not very suitable for internal insulation due to its low environmental friendliness. In addition, rats and mice often damage styrofoam. Expanded polystyrene can be used not only for wall insulation, but also for the ceiling. Quite often, polyurethane foam is used to insulate houses from foam blocks. To apply it, you need special equipment. The advantages of the material include high adhesion to all types of surfaces. When installing this heat-insulating material, there is no need to pre-level the walls, apply primer and install the frame.

The material is easy to transport. It has a low weight, therefore it does not create an additional weight load on the foundation and walls. Its use allows many times to increase the strength, heat-shielding and sound-insulating properties. Polyurethane foam is resistant to temperature shocks, is mounted using seamless technology and does not need additional fasteners.

The disadvantages include ultraviolet intolerance. Direct sunlight gradually destroys the material. And with prolonged exposure to high temperatures and fire, it can become fire hazardous.

Helpful hints

Experienced builders recommend insulating structures with foam concrete only from the outside. External insulation allows you to preserve the functional area of the house or bathhouse to the maximum, since any interior decoration significantly “eats up” the usable space. The strength of the bearing retaining walls increases, since the insulation from the outside takes on most of the weight load on the walls of the building.

It is better to think over the insulation of the house at the stage of construction planning. In this case, it will be possible to make external insulation with the most suitable material, as well as choose the external finishing of the building that will protect the insulation (for example, facing bricks, plaster or finishing panels). Also, for some types of exterior finishes, it may be necessary to increase the thickness of the foundation, for example, for cladding with bricks.

The comment was sent successfully.