Subtleties of the process of thermal insulation of interpanel seams

The main problem of panel structures is poorly sealed interpanel seams. This leads to wetting of the walls, the formation of fungus, deterioration of sound insulation, freezing and ingress of moisture into the seam. Such joints not only violate the comfort in the apartments, but can also lead to the destruction of the slabs. To get rid of this problem, it is necessary to repair and insulate the interpanel seams.

What is insulation for?

Exterior walls in panel buildings are usually a three-layer structure. On the inside and outside there is reinforced concrete, between which insulation is installed. The panels themselves reliably protect from the cold, but the seams between the plates are blown by the wind and are a traditional cold bridge. Even if the seam is well sealed, but the house is not insulated, the apartments lose their temperature.

In cases where the insulation is performed poorly, problems may arise:

- insufficient heat in the apartment, provided that the batteries are hot;

- freezing of the inner walls opposite the seam;

- the formation of condensation and fungus;

- destruction of the finish - wallpaper peels off the fastest, paint and decorative plaster will last longer.

Due to the fact that the seam is leaking, rainwater will enter it, which will lead to the destruction of the main walls and to constantly dampness in the apartments. There are times when the interpanel seams are poorly insulated and poorly sealed on both sides. Accordingly, this is bad for the comfort and warmth in living quarters.

It is not difficult to understand that you need to insulate the seams. The following signs allow identifying the problem:

- uneven temperature of the inner wall - if it is colder in the area where the interpanel seam is visible from the outside, then it is clear that its sealing is poor;

- finishing disappears from the walls, and the room is constantly damp;

- on the facade of the building, one can see the insulation lagging behind the seam or its complete absence.

If you notice at least one of the above signs, you should contact the appropriate organizations for services, because it is quite difficult to insulate the seam with your own hands, and sometimes it is completely impossible.

Materials used

Insulation of interpanel seams is carried out using different methods and using a variety of materials. Each of them has both advantages and disadvantages, and the choice depends on the operating conditions and on the buyer's requirements:

- Often full seam sealing is used. For this, plastic solutions are used, which penetrate deep into the structure and fill all the voids. Fine gravel, expanded clay or sand is used as an aggregate. Today, you can purchase special insulation materials, which include foam balls. There are also mixtures with air particles, which retain heat in the room and do not let the cold through, they differ in their affordable cost.

- If the seams are at a great distance from each other, then it is appropriate to use soft insulation fibers. For these purposes, mineral wool is suitable, which has a high compression ratio, frost resistance and ease of work with it. The cotton wool particles are pressed into the seams, but be careful as the material is volatile and can damage the skin, eyes or lungs. Stone wool with long and strong fibers is safe to use.Installation is quick and easy, but you do not need to clog the seam with material too much, with a tight fit, the fiber will not provide heat protection.

- For small seams it is recommended to use polyurethane based sealants. The cost of this material is quite high, but you will need a rather large amount of it. Warming with such sealants is carried out in two ways. Surface - allows you to save material, the spray nozzle is placed in the seam and the cavity is blown out with a mixture. With the drilling of holes - the seam is expanded with a special tool, the foam is blown out in excess, so that its excess remains outside, which must be cut off after hardening.

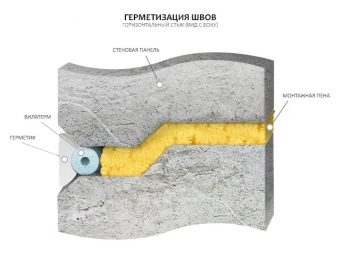

- Vilaterm tubes - material that is designed to insulate the seams. The material is a cylinder made of expanded polyethylene, the advantage of this technology is also the simultaneous protection from dampness. The tubes remain flexible even with temperature fluctuations. Their indisputable advantage is their long service life.

What kind of material to choose for the insulation of houses, it is better to consult with professionals about this.

Facade processing

Insulating a high-rise building from the outside allows you to achieve the best results. But in this case, only specialists will be able to perform the work, since high-altitude work is necessary. You can seal the seams yourself by renting scaffolding, they allow you to grip a large widthand there is room for the tools and materials needed for the job.

You can also get to the upper floors with the help of a tower, but there is little space on the site. The use of a tower is appropriate if you need long-term work in one place, for example, when the seams have expanded, or you need to clean the cavity from the old insulation.

Turning to professional climbers, be sure to check the certificate confirming compliance with all established standards in the work. As a rule, climbers do not separately seal the seams, they insulate the inter-seam space monolithically, so that the cold does not penetrate inside in any way. Warming is carried out on a thoroughly cleaned and flat surface.

Be sure to check that the joint of the insulation elements is not in the same place with the joint of the plates. In this case, a cold bridge is formed and it will be very difficult to correct the error.

The price of insulating the facade of a multi-storey building depends on the running meter, as a rule, experts charge no more than 350 rubles for one meter. You can calculate the approximate cost yourself, you just need to multiply the running meters of your living space by the cost per meter.

Sealing an apartment does not take too much time, first of all, the period depends on the amount of work, on average it can be done in 1-2 days. All documents required for construction work are provided by a company specializing in facade insulation. The client only has to submit an application addressed to the Chief Engineer.

Internal work

You can also insulate the seams from the inside with your own hands, without the involvement of professionals. Such work can be carried out at any time of the year, there is plenty of room for tools and materials. Before proceeding with the thermal insulation of the joints, it is necessary to remove the old plaster or putty. If necessary, it is also necessary to dismantle the old insulation. Thermal insulation must not be started without removing old materials. After all, their service life has already expired or the installation does not meet the requirements, as a result of which the effectiveness of the new thermal insulation will be minimized.

After dismantling old materials, the surface must be carefully leveled. If the cavity between the slabs is through, fill it with bonding mixtures. For such purposes, a cement-sand mortar is best suited, which will close the gap for a long period and reliably fasten the structures.The main problem of working with these defects is moisture ingress, therefore, waterproofing mastics must be used.

The mixture is applied with a brush, spray gun or a special spray. After the material hardens, a waterproof elastic protection is formed, which, even after slight shrinkage or displacement of the house, will remain intact. If the seams are small, then the space is filled with sealant and then sealed with electrical tape.

Insulation during construction

Earlier, during the construction of houses, tow or rubber was used to insulate the seams. Today, these materials have been replaced by a key, cement mortar and a swelling cord made of hydrophilic rubber. But the work from these mixtures cannot be called high-quality, during the installation work there are still gaps, which later let the cold pass inside.

Only polyurethane foam is capable of qualitatively filling the voids in the seams between the panels, which spreads evenly and fills the entire space completely, without the slightest gaps.

It is used in combination with sealants, which also boast excellent performance and durability.

Sealing the joints of loggias and windows

The device of loggias and balconies implies the presence of joints between the plates and the walls, through which water gets inside during rain. Due to constant dampness, construction materials will gradually collapse, fungus and mold will form on the walls. If the loggia is not yet insulated, and cold air enters it, the furniture deteriorates, and the level of comfort inside is not at all what the residents expect. To prevent drafts and remove cold bridges, you need to take care of high-quality thermal insulation.

The main reasons due to which water flows onto a balcony or loggia include:

- poor quality sealing;

- damaged roof;

- bad ebb or none at all.

To determine the cause, as well as plan a further action plan, you need to invite a specialist to inspect the premises. A prerequisite for thermal insulation is the processing of the joints of the wall and ceiling slab. If you ignore this process, in the near future, water that will accumulate on the stove will begin to get inside.

Sometimes people complain that after installing windows on the windowsill and slopes, water seeps out. This may occur due to the fact that there is no sealant at all between the ebb and the wall, or there are no ebbs.

Modern materials presented by well-known manufacturers allow you to quickly and, most importantly, qualitatively, to perform thermal insulation of panel joints. If you can't do the work outside on your own, and there is no financial opportunity to order the services of specialists, do not despair, because you can insulate the joints from the inside. To avoid unpleasant consequences due to incorrectly performed work, it is recommended to immediately contact the professionals.

About the technology of insulation of interpanel seams, see below.

The comment was sent successfully.