Base: functions and types of structures

Not everyone knows and, most importantly, understands why the basement of the building is needed. From a technical point of view, a plinth is a structural element that is located between the foundation and the building frame. It performs many tasks.

Peculiarities

Technically speaking, a plinth is that part of the foundation that is located above ground level. Its main purpose is to evenly redistribute the load on the supports in order to increase the stability of the structure and a long service life.

The plinth solves a number of important tasks:

- is the basis for the construction of the building frame;

- in the presence of a basement floor, it functions as walls;

- special air vents are mounted in the basement, which play the role of ventilation holes, thanks to this, the basement is well ventilated and does not rot under the influence of high humidity and low temperatures;

- the height of the plinth protects the floors from the cold coming from the ground.

All this determines the special importance of the base for the strength and durability of the whole house, which is why its competent arrangement is very important.

If the surface of the basement is not covered with finishing materials, then it quickly becomes dirty, which can cause its rapid destruction and deterioration of the state of the foundation and floors of the entire structure.

The facing material protects the foundation from damage by fungal microorganisms and mold, and also prevents the appearance of "insect colonies" under the main part of the house.

It is very important to pay special attention to the insulation of the basement, since basements function like a large accumulator, sucking all the heat out of the building, and even a warm floor cannot prevent this. And in addition, the insulated basement is important for maintaining the strength of the structure, since in severe frosts, erosion processes in the foundation quite often begin.

A stylish basement can become a decoration of a building, an accent that will emphasize the design solution of the facade and the impeccable taste of property owners.

Views

The basement plays a very important role in all buildings where there is a corresponding floor or a large basement.

In terms of structure, plinths are:

- sinking;

- speakers;

- aligned with the outer facade.

The western option is most popular, since it requires less materials for its arrangement, and in addition, it does not flood with rain, and this is very profitable, since it allows you to abandon the installation of gutters. The sinking base, as a rule, is protected by a layer of effective waterproofing, therefore it tolerates rain and snow melting better, and it lasts much longer.

Purely visually, the sunken plinth looks like the upper part of the building protrudes above the lower one, this contributes to the fact that a double protection from moisture is formed, so that the basement remains dry.

The protruding basement looks more aesthetically pleasing, however, the arrangement requires the mandatory installation of additional ebb systems along the upper edge in order to protect the basement from moisture ingress.In recent years, modern housing construction has practically abandoned protruding plinths, since this option requires much more effort, time and money for its arrangement, and in addition, it has a reduced resistance to wind and melt water, is prone to corrosion and, as a result, faster wears out.

In fairness, it is worth noting the fact that the thermal insulation with such an organization of the base is higher than with other options.

And you will also need to close the waterproofing layer and install a drainage mechanism to remove rainwater. This basement makes sense if the exterior walls of the house according to the technical design are too thin. At the same time, it looks quite aesthetically pleasing, giving the entire structure a tangible monumentality.

But experts strongly advise against building a basement flush with the outer wall. In this case, the owners of the house will not be able to protect it with a layer of waterproofing, which means that the risk of excessive dampness in the most vulnerable zones will increase, and the aesthetics of this design is “lame” - a foundation aligned to the walls will never make as good an impression as a relief one.

Dimensions (edit)

The size of the basement is influenced by the type of foundation, the general design of the house, the basic parameters of the soil, as well as the purpose of the basement - there are special instructions for this. For example, if a heating boiler is located in the basement of a private house, then the basement must necessarily have access to the street.

Many owners of residential real estate believe that if they do not equip the basement, then there is no need for the basement, and the foundation can be built flush with the ground - and this is a very big delusion. The main task of the basement is not to protect the basement, but to isolate the facade and floors of the building from contact with the ground. It is in order to prevent the groundwater from rising upward by capillary through the concrete, between the front and basement part of the wall, a layer of waterproofing, usually roofing material, is necessarily laid.

In accordance with the standards, in an ordinary private house, the basement should rise above the ground at a distance of about 30-40 cm.If the building is built of wood, it makes sense to make the basement higher - 60-70 cm, and if the house has a semi-basement the basement should rise 1.5-2 meters above the ground level at all - it is this height that gives the maximum compliance with existing standards. The height of the base does not depend in any way on the material from which it is equipped, be it stone, brick or cinder block options - any coatings suffer from water equally.

It is very important to take into account the natural and climatic zone, namely: the average temperature in the cold season, as well as the average rainfall. If you are just planning to build a house, then the approximate height of the basement can be calculated empirically - for this, over the course of several years, you will need to measure the depth of the maximum snow cover, then find the average value and add 10 cm to it.

According to the current SNiP, the minimum base height should be 20 cm, however, from a practical point of view, this parameter should be higher.

Of course, the arrangement of a high basement will cost more, since it requires more costs for concreting work. Nevertheless, this is exactly the case when economy should fade into the background, in priority the strength of the base and high performance.

Let's figure out why the height is so important, and what the size of the base affects.

The main thing is that the degree of protection of the entire building and its internal premises from adverse environmental factors and mechanical damage will depend on its dimensions. At the same time, you need to set the height wisely, since every extra centimeter will significantly increase the total cost of construction work.In addition, it is important to focus on protecting the lower part of the facade from frost by laying a layer of high-quality thermal insulation from the outside or from the inside.

If you have any difficulties in calculating the optimal basement height, then you should contact a specialist. Their help, as a rule, is not gratuitous, but it is better to spend extra money on competent planning of the house than to later give much larger sums for its reconstruction.

Materials (edit)

For the construction of the lower part of the building, as a rule, one of the following materials is used:

- stone - is distinguished by its strength, but requires high-quality thermal insulation;

- brick is the most common material for arranging plinths;

- concrete - gives good stability to multi-storey buildings;

- foam and gas blocks - allow you to build a base as quickly as possible, hygroscopic;

- FBS blocks - have a high margin of safety, are used in multi-storey construction.

The choice of a suitable material is made on the basis of the existing project documentation. Let's dwell on the advantages and disadvantages of each of the listed materials.

A natural stone

Stone is a rather expensive finishing material. At the same time, it is characterized by increased strength and durability. This type of plinth finish has been relevant for several decades, and only granite material and marble or limestone cladding can compete with it.

Naturally, a non-natural version of the stone is used; for arranging the basement, cut slabs with a textured surface are produced, in which decorative protrusions are preserved to give a natural look.

Plinths made of natural stone look very elegant and original. Such a foundation is optimal for private houses and cottages built in classical or English style. At the same time, the process of installing a stone basement is quite laborious and requires a lot of effort, time and money, and in addition, it requires professional equipment, which is not available in every home, so today such a basement is rather a rarity.

Brick

A brick base is considered the most popular option, it has a relatively low cost, and the installation itself does not present great difficulties for a person who has at least a minimal skill in construction and finishing work.

In practice, several options for the construction of such foundations are used, they are based on the combination of various materials. Thus, the brick surface, as a rule, is not the final appearance, it can be painted or plastering. It is important to keep in mind that only silane-siloxane paints are used in the decoration of the base; they are distinguished by good hygroscopicity and reliably protect the base from water penetration.

Plasters should also be used special designed for facade work. For the arrangement of the basement, brick of the M-50 brand is used, the minimum masonry is 4 rows.

Concrete blocks

This material is also popular in construction work due to the strength and stability of such a base.

The current standards impose strict requirements on the weight of the blocks used: when doing manual masonry, it should not exceed 100 kg, and when using special metal or wooden levers, a block weight of 500 kg is allowed.

This option is perhaps the only one that is suitable for arranging a basement floor - that is, in cases where the basement is not just a basement, but a real living space.

When laying such material, it is necessary to take into account:

- the use of reinforcement to increase the stability of the building;

- pouring the bottom layer with concrete;

- the need for thermal insulation of the base;

- filling is performed in stages in several stages, avoiding the formation of seams in any direction.

Monolithic base

With the use of concrete, a monolithic basement is also equipped, such work is based on the construction of a formwork frame, where cement mortar is poured, after which it hardens 2 in 1 is obtained: both the foundation and the base at the same time.

At the same time, to design such a plinth, corrugated fiberglass, rubber mats and other materials are often laid in the formwork, which give the plinth a wide variety of textures.

After the concrete hardens, the formwork is removed, the surface is cleaned, voids are closed and external defects are removed, then covered with a reinforcing mesh and a topcoat is applied.

Foam block

A foam block basement is another option for arranging a concrete foundation.

This material is distinguished by a porous structure, which is due to the peculiarity of the hardening of the foaming agent, and sand, cement and water, mixed using a special technology, are also part of the components.

As a rule, such a coating looks like a bar externally, but sometimes it is produced in other versions: with spikes, grooves, and the like.

Foam blocks are optimal for arranging the lower part of the facade, since they are very durable and stable, but at the same time they have a low weight (14-20 kg), and thanks to their dimensions, all work can be carried out in the shortest possible time.

Please note that the use of this type of concrete structures requires mandatory vapor and waterproofing at the stage of preparatory work.

Wood

This option is used very rarely and, as a rule, is popular in ecovillages, where residents prefer wood as the main building material. With this option for arranging the basement, completely round logs or a bar with a section of 15x15 cm or more are used.

Device

The device of the basement is a process that combines several important stages: equipment of the ventilation system, waterproofing, the construction of the basement itself and its finishing.

Ventilation

The humidity level in the basement is always high. This is due to the fact that moisture and evaporation rises from the soil base, which, having no way out, begin to be deposited on the surface of the bearing structures of knowledge. This has a rather detrimental effect on the operational properties of the latter, causes corrosion of the metal and rotting of wooden supports, which significantly reduces their service life. Unfortunately, this is far from the only consequence of moisture. The air in basements and basements is an ideal environment for the growth of life-threatening fungi and molds. These microorganisms lead to the development of allergic and bronchopulmonary diseases, since during inhalation they enter the lungs of a person, having the most destructive effect on them.

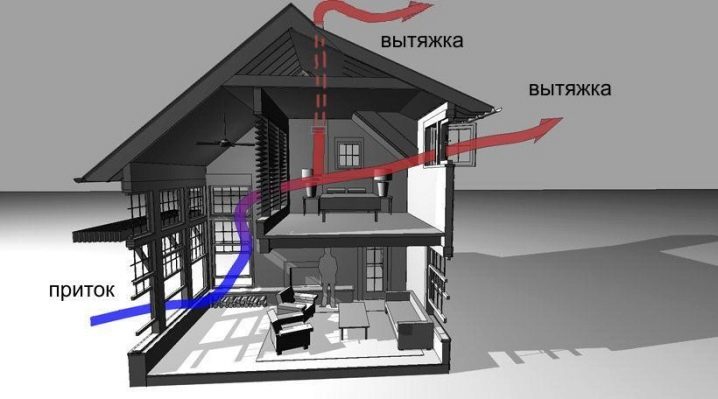

That is why the issue of ventilating closed rooms, especially basements, is always of particular relevance. The ventilation of the basement is arranged in two ways: natural and forced.

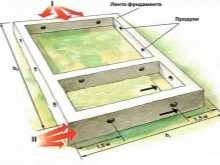

Natural ventilation involves the arrangement of special vents, that is, holes that will facilitate free air circulation. Ventilation of this type is provided due to the temperature difference between the air inside and outside the basement. Depending on the design of the base / plinth, the ventilation device may differ. For example, if the basement is built of monolithic concrete, then during the installation of the formwork, small sections of asbestos pipes are laid in advance, the dimensions of which directly depend on the size of the ventilated room.

The vents are closed with special grates that prevent rats, mice and other rodents from settling in the basement of an apartment building. These gratings are usually made of polymer materials.

There are no standards regulating the amount and size of air ducts, so the owners of a private house must plan ventilation openings on their own, based on data on the wind rose, seasonal temperature fluctuations and precipitation. However, any professional builder can choose the optimal number of ducts and their location, based on their experience with ventilation systems in buildings of different types.

Forced ventilation has a slightly different mechanism of action and a different scope of use. This method is optimal for large basements where natural air circulation is ineffective.

To ensure ventilation of such spaces, ventilation pipes are laid in the box, which come out of the roof. Their height should not exceed the level of the roof ridge. For very large rooms, an option is used in which the inlet ventilation pipe is mounted at the level of the base, and the outlet - above the level of the ridge, while fans are installed in both pipes.

Nowadays, engineering has taken a big step forward, which is why there is a wide variety of automated forced ventilation systems on the market associated with sensors for determining the level of humidity in the basement. Thanks to the functioning of such systems in the basement, any increase in the humidity level above the established one is excluded; the system includes intensive air removal in cases when the indicator reaches a critical level.

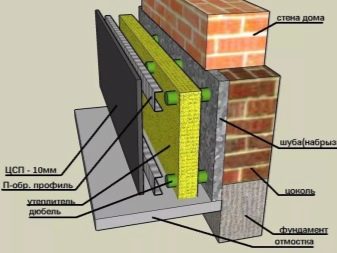

Warming

The air temperature in individual rooms of the entire building largely depends on the literacy of the arrangement of the basement, especially those whose walls face the street. And in general, the microclimate in a residential building is largely formed due to the degree of basement insulation. This is not surprising, because the base is in direct contact with the ground, supporting supports and the floor.

If insufficient attention was paid to thermal insulation during the arrangement of the foundations, the room will be cold and damp.

High-quality insulation of the basement neutralizes the effect of cold bridges and leads to significant heat savings, which reaches 15-20%. This stage is so important, because at least 15% of the heat from living quarters can go through the walls of the basement, as a result, freezing of the foundation and supporting structures occurs. As a result, materials begin to deteriorate, and the air in the basement becomes damp and "rich" in mold, mildew and moss. In addition, a feature of many regions of Russia is the clay structure of the soil, the soil is characterized by a high degree of heaving, and in conditions of low temperatures a phenomenon called "frost heaving" occurs - the soil increases, which often causes deformation and displacement of the building frame. Thermal insulation will be able to prevent this process and, accordingly, reduce the risks of distortions and subsidence of structures.

The basement can be insulated from the inside as well as from the outside.

Insulation performs the following tasks:

- contributes to the formation of a favorable microclimate;

- protects the facade from soil and atmospheric sedimentary moisture;

- minimizes the risk of condensate settling on wooden bearing elements of the foundation;

- extends the life of the house as a whole.

From a practical point of view, both internal and external insulation of the basement gives the same result. The only difference comes down only to the appearance of all structures as a whole - insulation from the outside involves finishing finishing work, which makes the basement more attractive and aesthetic.

The thermal insulation materials used must necessarily meet a number of requirements:

- low thermal conductivity - it is from this parameter that the property of retaining heat in the room primarily depends;

- hygroscopicity - the coating should not absorb water, since even its minimum concentration significantly degrades the operational parameters of the insulation and shortens the service life;

- high compressive strength - this allows the coating to tolerate well the pressure exerted by the soil.

All of the above requirements are best met by board materials. as well as modern sprayed insulation.

Waterproofing

There are a lot of options for arranging effective waterproofing; conditionally, they can be divided into several types. It can be:

- penetrating;

- pasting;

- painting;

- coating waterproofing;

- arrangement of a clay ring;

- drainage.

A clay ring is formed in the part of the facade, which is located just below the ground level. To do this, the clay composition is mixed and laid down, after which the foundation should be tied around the entire perimeter of the basement to a depth of about 20-30 cm. Further, the clay is compacted as much as possible and sprinkled with sand and crushed stone.

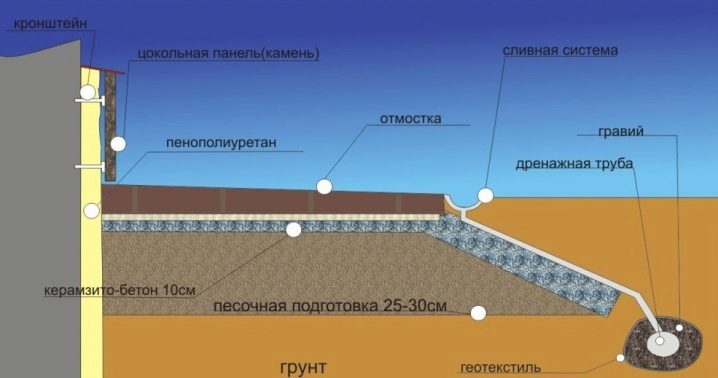

Blind area and drainage are also effective methods of waterproofing a basement. At the same time, for the lowest level of the basement, a drainage pipe is installed, through which groundwater will be diverted.

The blind area, on the other hand, differs in location - it fits exactly in the place where the top layer of soil is in contact with the base.

The width of the blind area is about 1 meter, as a rule, asphalt or concrete is used for it, which are placed along the perimeter of the building frame. At the same time, it is most important to equip a good sealing of the places in which the base is in contact with the blind area. Urethane mastic is suitable as a sealant. This structure must necessarily be located with a slight slope.

These two methods are considered the easiest and fastest in terms of their arrangement.

The glued waterproofing is based on the use of roll materials made of bitumen or synthetic polymers, which are glued in several layers, less often they are fused. In some cases, multilayer membranes or isospan can be used. The minimum number of layers is 2, while it is necessary to form an overlap of 15-25 cm.

According to professional builders, this method requires preliminary surface preparation and strict adherence to the temperature regime during work.

The advantages of this method are obvious:

- low price;

- plastic;

- environmental Safety;

- high adhesion to stone surfaces, as well as to concrete and wood;

- simplicity and ease of installation.

All work can be carried out independently without the use of professional equipment.

However, not everything is so perfect - the gluing waterproofing has its drawbacks. The surface must be pre-cleaned and specially prepared: leveled and dried. In addition, the tensile strength of rolled materials raises great doubts, and under the influence of external unfavorable factors, such coatings begin to deform and become unusable.

As the name suggests, coating waterproofing is made using coating materials - most often bituminous and polymer mastics are used for this, liquid rubber is considered a more modern option. This waterproofing is ideal for plinths made of brick and concrete.

This coating is characterized by smoothness and uniform structure, absence of seams and good water resistance. At the same time, such materials are characterized by a short period of use - after 5-7 years they are covered with cracks.

Liquid glass can become a good alternative to the listed compositions - this is an innovative material that has been in the highest demand among users in recent years. Such insulation is easy to apply, environmentally friendly, resistant to temperature extremes and acid-base solutions.

Internal insulation allows the use of the same materials and methods as external insulation, for example geotextiles and roll materials will effectively protect the plinth from internal moisture. The choice can be stopped on other compounds: bikroelast, euroruberoid or hydrostekloizol.

However, sheet materials can also be used. They should be preferred in regions with snowy winters or in homes close to flood zones during the spring thaw. The waterproofing sheet withstands large volumes of water under high pressure. In this case, it is necessary to use steel with a thickness of at least 4 mm.

How to choose?

The most durable and strong, from a technical point of view, is the basement, equipped with monolithic reinforced concrete, since only the highest quality cement and river sand without any impurities are used for it. The frame of such a base is reinforced with reinforcement.

And here the most affordable material is brick. No less popular is a plinth made of concrete blocks, which are connected to each other with concrete mortars.

For one-story houses, natural stone is most often used, which can be sawn or "wild". Masonry is carried out only using cement mortar, since when arranging a basement of this type, it becomes necessary to tightly seal all the holes between the stones so that the whole structure is a single whole.

As for the design of the basement, it directly depends on the characteristics of the foundation and not vice versa. The priority parameter in the construction of a house is the foundation, and the arrangement of the basement is, albeit important, but nonetheless of secondary importance.

If, with the help of the foundation, the facade is raised to a considerable height, at which the contact of the wall with melt water is completely excluded, then we can assume that the task of the basement has already been solved. It is this situation that arises when erecting foundations of pile and columnar types, while the basement serves as a fence for the space under the house and there are no special requirements for its strength and waterproofing.

That is why, in most cases, the arrangement of the basement is reduced to the purchase of finishing material - there is a great choice here: from siding to natural granite. This type of base is called decorative and it will be a big mistake to use it as a fence for filling inside the sand, since the base can only perform support functions if the structure has its own foundation and is characterized by high resistance to tipping.

If the basement part is placed on a strip foundation, then it combines the functions of a barrier and a bearing support, in this case, waterproofing and insulation of this part of the house is mandatory.

If the house is built on screw piles, siding should be preferred.

How to do it yourself?

In order to build a base, you need special tools:

- shovel;

- cement dilution tank;

- concrete mixer or screwdriver;

- trowel;

- paint brush or roller;

- centimeter or tape measure.

As a rule, home craftsmen build a brick base on their own. All other options require a more professional approach, so we will dwell on this type of work in more detail. For masonry, you need to purchase bricks, cement, sand, as well as waterproofing material, bitumen-based mastic and primer.

The scheme of work here is as follows:

- dry the equipped foundation, and treat its upper edge with a paint brush with a primer;

- along the edge of the primer, it is necessary to apply a layer of mastic, then fix the waterproofing material and roll it for a better fit, and then reapply the waterproofing;

- lay out the first row of masonry in the corners, then, using a centimeter or tape measure, measure the conformity of the size of the basement for accuracy of compliance with the project, while the permissible deviation should not exceed 3 cm;

- mix the sand-cement mortar;

- using a trowel, lay the mortar on the corner masonry, then lay the first row of masonry around the perimeter, cover with a layer of mortar and strengthen the reinforcing mesh in it;

- carry out subsequent layers of brickwork.

Tip: the work will go faster and easier if you pull the cord around the perimeter - this will allow you to build layers evenly and without deviations from the required masonry parameters. By the way, to decorate the knot, a plinth strip is used.

Advice

When looking at private houses and cottages, the walls of which are located high above the ground level, sometimes it is not so easy to guess that this is a basement. If it is lined with high quality, it can look very decorative and aesthetically pleasing.

Finishing the basement can be done in two ways:

- finishing coatings are attached directly to the surface of the base;

- a crate of beams or a metal profile is installed, to which decorative elements are mounted.

Most often used for cladding:

- stone - it is decorative and resistant to mechanical damage, such a facing requires the use of the services of professionals;

- plastic panels - modern industry produces panels that imitate the color and texture of natural materials (wood, stone and minerals), the installation of such plates is carried out on a pre-equipped frame and can be done on our own;

- ceramic tiles - offered in a large selection of colors and shades, allows you to create any pattern and ideally emphasize the thoughtfulness of the exterior;

- plaster - as a rule, decorative varieties of plaster intended for outdoor use are used.

The last finishing option is the most budgetary.

It is up to you to decide what kind of plinth to be, the main thing is that it reliably protects the building, and its aesthetics be a pleasant bonus to strength and efficiency.

Beautiful examples

The plinth, as an important part of any exterior, needs decorative finishing. Here are some examples of stylish and aesthetic design options.

It is not at all necessary to highlight the plinth on the facade, the designers allow the use of one material, for example, finishing bricks or siding.

Plastering is a trendy option. The main thing is to use a material that is resistant to moisture, for example, terrazite. Its advantage is the ability to choose any shade of finish, which can be updated at any time, however, the repair of such a coating will have to be done more than once.

Another type of base / plinth finish is panels, which are quite widely represented in any hardware store. This is a common option that perfectly mimics natural textures.

Clinker brick finishing is a rather expensive solution, but worth it.

Porcelain stoneware looks very aesthetically pleasing.

Facing the basement with a stone is an even more expensive option, however, if you want your home to be truly luxurious, you should go for such a expense.

Tips for laying out the base - in the next video

The comment was sent successfully.