Features and Applications of Linear Panels

Linear panels are a relatively new, but already well-proven material. All consumers need to understand its use for fences and other structures. It is especially worth dwelling on the dimensions of the facade and other panels, on the installation of a linear metal profile.

Peculiarities

It is hardly possible to surprise at least someone in 2020 with metal siding. Steel and aluminum products are durable and beautiful at the same time. However, you should not assume that the choice is limited only to typical lamellas and base / plinth panels. A number of other options for metal profiles are presented on the market, among which linear panels stand out. Such constructions can be used very widely.

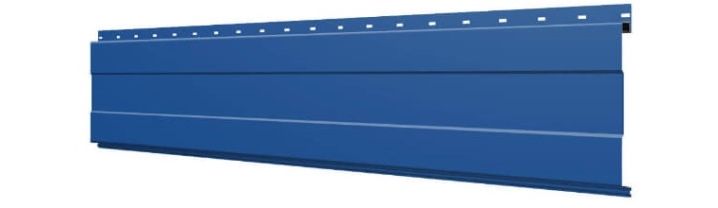

Externally, the linear panel is similar to the facade cassette. It is a strip of metal with box-like ends. But the device is still different: the width is significantly less than the length, which allows such structures to be classified as siding. It is the superiority of length that determines such an unusual name.

To obtain linear panels, aluminum or thin steel sheets are used.

Cold roll forming allows for increased technical performance. The base element (the so-called strip) is a steel strip that is rolled on forming rollers. This procedure is called profiling. As needed, the finished structures are perforated. After the completion of the main work, they are cut to the exact size and the batch of goods is packed.

It is necessary to pay attention to the pros and cons of linear panels for end users. They must be covered with a polymer layer that reliably blocks ultraviolet radiation. Polymers are also resistant to mechanical stress, which improves the parameters of the product as a whole. Polyester, better known as polyester, is often used.

In addition to it, the following can be used:

-

acrylic (very well tolerant of exposure to sunlight);

-

plastisol (chemically modified PVC);

-

polyurethane (scratch and shock resistant);

-

polyvinylidene fluoride.

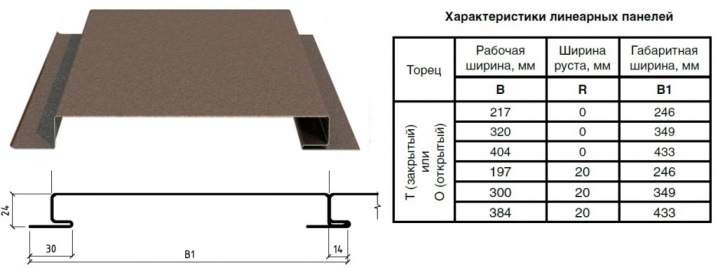

The dimensions of the panels can vary quite a bit. Both thick (1 mm) and thin (0.45 mm) products are known. In length, they can reach 900-6000 mm. In width - from 1350 to 3520 mm. Experts point out that it is most convenient to be guided by the area of the facade or a multiple. In general, linear panels:

-

designed for cold up to - 50 and for heat up to + 50 degrees;

-

can be mounted both in 15-degree frost and in summer, as long as the temperature does not exceed + 35 degrees;

-

have a small number of joints (which increases the strength of the structure and reduces the number of cold bridges);

-

weigh relatively little;

-

thanks to the sliding fastening, they allow to do with the lightest types of frames;

-

they are successfully placed not only on flat, but also on cylindrical, other complex surfaces;

-

installed horizontally, vertically, and in a diagonal plane - and without any auxiliary structures;

-

mounted vertically from left to right and right to left;

-

serve under normal conditions for at least 25 years;

-

can be damaged by impacts (this is especially typical for aluminum products);

-

subject to corrosion (if the polymer layer is broken);

-

can accumulate static electricity and "attract" lightning, as a result of which you have to spend a lot of effort and money on equipping a house with a reinforced lightning rod.

Applications

Linear panels, especially due to their electrical activity, are rarely used for cladding the facades of low-rise residential buildings. However, they are regularly bought to decorate the facade walls:

-

stadiums;

-

industrial enterprises;

-

educational institutions;

-

warehouses;

-

administrative buildings;

-

apartment buildings;

-

gazebos;

-

summer houses;

-

baths and saunas;

-

garages;

-

auxiliary facilities (utility units).

Such designs allow you to combine different tones, sometimes 3 or even 4 colors. This does not interfere with ensuring the unity of the appearance of the building. Just look at the attached photographs of the facades.

Of course, it is not necessary to mount such products precisely on an external wall. They still make good fences - beautiful, strong and durable at the same time. Varying the length and width in a large assortment allows you to choose exactly the solution that is needed in a particular case. You can do on the basis of these constructions:

-

bends;

-

arches;

-

columns.

Linear ceiling and wall panels are also very diverse. There are solutions:

-

different colors;

-

with perforation;

-

with longitudinal stripes;

-

perfectly smooth;

-

corrugated.

Views

Linear panels are distinguished by the type of end. In typical "boxes" it is hermetically closed, but there are also solutions with an open end. As for the rustic and non-rustic versions, they roughly correspond to the seam and seamless types of lining. Rust is a protrusion 2 cm long. When the product is mounted, something like a seam appears, and therefore the wall looks almost the same as when sheathing with the usual types of siding.

According to the external design, the surface of the panel is divided into:

-

smooth;

-

perforated;

-

assembled from thin strips;

-

types decorated with a checkerboard or other complex pattern.

In terms of installation and technical characteristics, all this does not play a role in use. However, the aesthetic difference is undeniable.

Vertical linear panels look unusual and are perceived very effectively. The vast majority of people agree that it looks pretty. It must be understood that such a solution is not so easy to install, and the demand for it is great, that is, stale goods prevail.

Lovers of simplicity and familiarity may prefer the horizontal model. Of course, all panels are metal, but what kind of metal or alloy is used is of no small importance. Steel structures are very strong and reliable. They do not crack even with strong impacts. It is even difficult to imagine the impact that is capable of tearing, crushing or bending such a product.

But steel:

-

heavy;

-

highly susceptible to corrosive processes;

-

lets in a lot of heat.

Aluminum structures are a compelling alternative. They are much lighter, which simplifies the arrangement of facades and fences. Installation is possible without additional strengthening of the foundations.

Aluminum is not susceptible to rust formation. But its strength is low, and its thermal insulation properties are low.

Dimensions and weight

Narrow models are those that are designed to work with soffits and ceilings. A wide panel is taken to clad the facade and make internal partitions. Structures with a length of 200 mm are very rare. Galvanized models are more common, the largest parameters of which are 1000x1250 mm. Composite solutions reach 1250x4000 mm. If desired, you can order sheets of a different size, but it is absolutely impossible to find information on the mass of the panels.

Colors and texture

Smooth linear panels are widely used for walls in commercial and industrial buildings. Since there is no relief on the surface, it will be very easy to care for. The mounts are placed completely hidden.Corrugated products are more aesthetic versatility. With the help of such material, not only the walls of houses are trimmed, but also ceilings, verandas, baths, gazebos and so on.

In appearance, linear panels can be designed:

-

under the tree;

-

under a brick;

-

under the tiles;

-

under a stone;

-

in white;

-

in black;

-

in gray;

-

in cherry;

-

in chocolate color.

Linear models with a stripe are suitable for interiors, for verandas and canopies. Under such profiles, it is possible to carry out hidden installation of electrical wiring.

The embossed strip dampens the visual weaknesses of the premises and increases the rigidity of the structures. Perforated models are mainly needed for filing protruding parts of the roof. This ensures optimal ventilation of the space under the roofing material and keeps it dry.

Manufacturers

Popular linear panel from PKF "Prestige-Facade"... The manufacturer promises a sleek look and modern effect. The description also says that its products are durable and easy to install, that they can be repaired without any problems. Prestige-Facade supplies panels with a width of 100-1100 mm. For their manufacture, galvanized steel is used with a layer of 0.035 to 0.12 cm; galvanizing is carried out in full compliance with GOST.

It is also worth emphasizing that this manufacturer uses CNC machines. It is not difficult to dock individual panels, it is not difficult to maintain corners. The color palette is not only RAL, but also images from the Design, NSC catalogs. The staining itself is performed using Turkish paints. They will not fade even with prolonged use.

A good alternative is linear panels from MetStal... The firm claims that it uses highly precise production equipment. All products have the required quality certificates. It is also stated that structures can be made exactly to the size of the customers. There are, of course, other manufacturers as well.

So, company "Queen" supplies products of various sizes. They can be mounted both vertically and horizontally. The material can be used both indoors and outdoors. Easily implement a wide variety of design concepts. Still very good products are supplied by "First Facade Company" - one of the leaders in this segment in the north-west of Russia, the designs fully meet the Gosstroy standards.

Other suppliers worth noting:

-

plant "Metallist";

-

"Metal profile";

-

"First Roofing Plant";

-

"Spetsprokat";

-

Steel Construction Company.

Installation technology

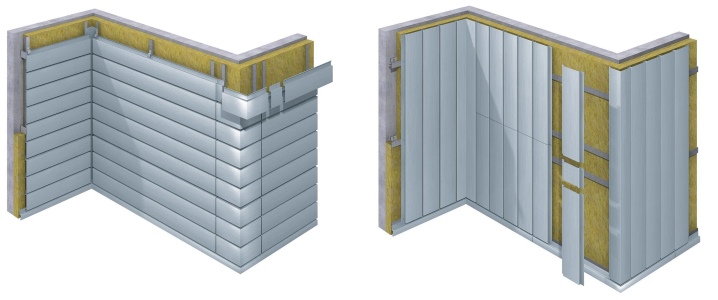

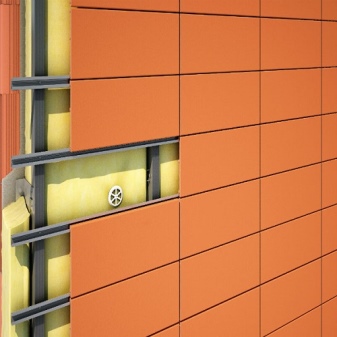

Of course, it is best to mount according to the manufacturer's instructions. But the general requirements must also be taken into account. The procedure is very complex and is divided into a number of stages. If you make mistakes, then in the future, the cladding will not satisfy the needs of consumers. In general, you can cut metal in the same way as usual, just more thoroughly and neatly. The installation of ventilated facades itself is carried out in about the same way as the installation of conventional siding, metal cassettes.

Whether it is necessary to use thermal insulation materials is determined taking into account the climatic parameters and the purpose of using the building.

Experienced installers work quickly, but without special training, all this is impossible. First of all, professional work begins with technical expertise. This is a complex set of works that allow you to establish the general condition of the building and the permissible load level. The next step is the preparation of design and technical materials, in accordance with which all work will be carried out.

The markup is performed as accurately as possible. Its quality determines how reliably the cladding will be fixed, and how the operational parameters will be ensured. Typical distance between brackets is not less than 0.5 and not more than 1 m. Along with the brackets, it is required to install special thermal spacers that prevent heat leakage and cold penetration.With a well-chosen type and size of the bracket, it is possible to cope with rather significant fluctuations in the vertical of the walls.

Then it's time to lay out the insulation. Mineral wool mats are sometimes glued onto special compounds. But it is still more reliable to use dowels with an umbrella head. For 1 sheet of insulation, 5-7 dowels are used. Then lay out a protective membrane; at the edges it is fixed as securely as possible so that air circulation does not wrap the panels.

If the gap is completely eliminated, air will not circulate through the facade complex at all.

The choice of horizontal or vertical profiles is determined by the direction in which the panels themselves will be laid out. After installing the profiles, they need to be screwed to the brackets. After screwing in the self-tapping screws, ebb tides, openings for windows and doors are placed.

Auxiliary profiles are placed on the perimeter of the openings. With their help, they will fix the finishing material inside the slopes. Only the linear panels themselves are mounted last. This process can have various subtleties, depending on their design and the characteristics of the wall itself. It is necessary to find out all such nuances in each individual situation.

The comment was sent successfully.