Facing brick for the facade: types of material and features of its choice

The façade of the building serves to protect and decorate the walls. That is why the selected material should be characterized by strength, durability, weather resistance and low moisture absorption. Facing brick is one such material.

Features and Benefits

Facing brick is a type of material intended for facade decoration. In this regard, the brick is also called "front" and "front". Like any finishing element, a brick performs 2 main functions - protective and decorative.

The protective function determines the compliance of the material with the following requirements:

- high strengthrequired to withstand mechanical stress, shock and wind load;

- low moisture absorption coefficient, meaning frost resistance, durability of the product, as well as the absence of mold and mildew in the room and on the surface of the facade;

- heat resistance, resistance to low temperatures and sudden thermal changes (a brick must withstand the most dangerous changes - jumps from low to high temperatures).

Given the laboriousness and considerable cost of installing a brick facade, a rare owner will agree to a structure's service life of less than two or three decades. However, subject to the masonry technology, such a facade has a 50-year or even more service period.

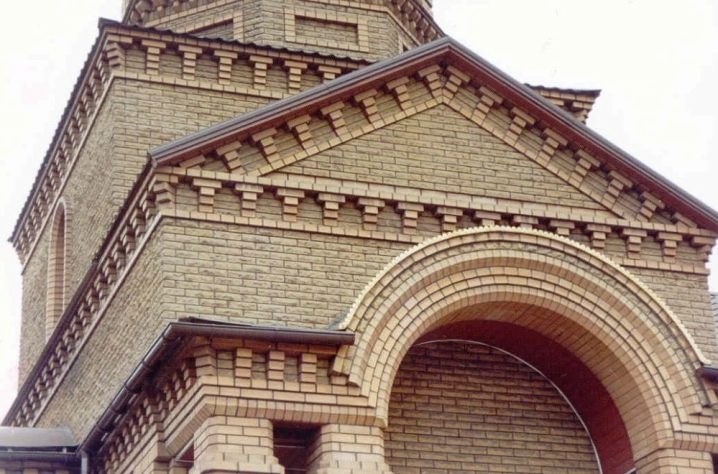

At the same time, the use of bricks for the facade opens up endless possibilities for its design. Different types of bricks, many options for masonry - all this makes brick cladding a real work of art.

In some cases, the use of this material as a finishing material is unacceptable. Let's dwell on this in more detail.

The brick, depending on the type, weighs 2.3-4.2 kg, respectively, a brickwork with an area of 1 m2 made of material with dimensions of 250 * 65 * 120 mm has a weight of 140-260 kg. It is not difficult to imagine how much weight the facade of even a small house will have.

This necessitates a reliable foundation for the facade. It will be possible to use a brick only if the existing foundation protrudes beyond the walls by at least 12 cm (the width of a standard brick) and has a suitable bearing capacity.

In the absence of such, it is possible to arrange a separate foundation for the facade masonry, connecting it with the main anchors, but this is not always possible from a technical point of view. In addition, the process is quite laborious and costly. Additional costs will also be due to the need to remodel the roofing system and gables, since with the increasing area of the building as a result of finishing, they will not be able to fully protect the building.

When constructing a separate foundation for the façade, it is imperative to connect the load-bearing walls and cladding. As a bonding system, special flexible polymer bonds or stainless steel analogs are used, as well as galvanized steel wire. One end of the wire is mounted to the wall, the other to the facade.This allows you to maintain the location of the facing row, preventing its removal or "run over" to the supporting structures of the building.

An important requirement is the ability of the walls to "breathe", that is, to let the water vapor accumulating in the room into the atmosphere. Compliance with this requirement is ensured by maintaining a 2-4 cm ventilation gap between the facade and the walls, as well as equipping the first air vents, which are located in the upper and lower parts of the facade.

Airflows are performed using special elements, or they can represent several unfilled vertical joints between bricks. The purpose of such elements is to ensure air circulation by sucking it in the lower part and outputting it in the upper part of the facade. Fresh air circulating inside the gap, as it were, blows through it, taking with it part of the water vapor.

Failure to comply with this requirement is due to the technical characteristics of the brick cladding (water vapor during freezing will destroy the brick, contributing to the appearance of cracks on it) and insulation (if any in the ventilation space), as well as the fallout of condensation on the surface of the walls and half-shelf inside the building.

Thus, the width of the façade foundation should increase by another 30-40 mm in order to organize the ventilation gap.

Moreover, in the latter, a layer of heat-insulating material is often laid to increase the thermal efficiency of the building. In this regard, the width of the gap increases by 5 (or 50 mm) more centimeters, which entails an increase in the width of the foundation to 190-210 mm and the need to increase its bearing capacity.

However, today narrower material options are on sale - their width is 85 mm (eurobricks), and sometimes it can reach only 60 cm.When using such a brick, you can reduce the protruding part to 130-155 mm.

If it is impossible to fulfill the described requirements for the features of the foundation and structure of the building, it is not necessary to abandon the idea of living in a "brick" house. There are worthy analogs of brick finishes - clinker tiles, facade panels that imitate brickwork.

Views

There are the following types of facing bricks.

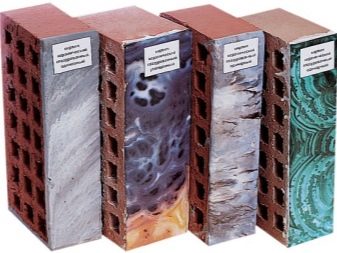

Ceramic

The most affordable option. The products are based on clay, modifiers to provide the finished brick with certain technical properties, sometimes pigments. Raw materials are formed into bricks, dried, and then fired in high-temperature (up to 800-1000 degrees) furnaces. The strength and quality of the finished product depend on the quality of the clay and the exact observance of the production technology.

Ceramic bricks can vary in shades, dimensions, texture, be hollow and full-bodied. Its shade ranges from light brown to brick red when it comes to raw materials without pigments. The shade is due to the peculiarities of the composition of the clay, the temperature and time of firing (the higher the temperature and the longer this process, the darker the product turns out). When pigment is added, the color of the brick varies from light, beige to dark gray, graphite.

The downside of the material is the tendency to the appearance of efflorescence - a whitish bloom that occurs when it comes into contact with salts of masonry mortars of low quality.

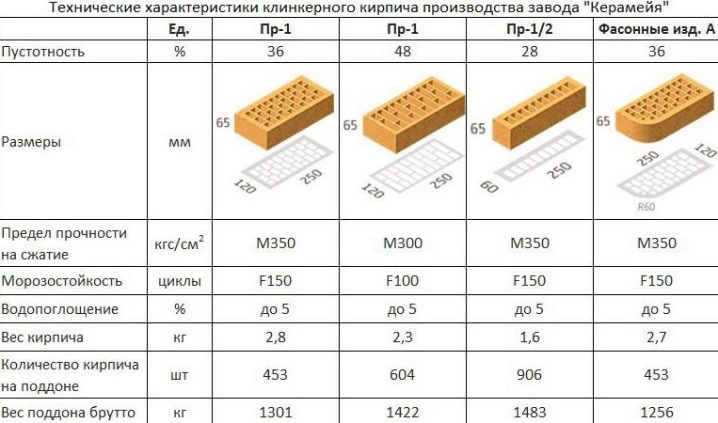

Clinker

It is also based on natural clay and a small amount of environmentally friendly additives, which are fired together in a kiln. However, the heating temperature is already at least 1300 degrees.

The result is a monolithic product, devoid of pores and voids. This, in turn, demonstrates increased strength (for comparison, clinker has a strength of M350, a ceramic analogue has a maximum of M250), as well as a minimum moisture absorption (1-3%).

Naturally, this also has a beneficial effect on the frost resistance of bricks - some types of clinker can withstand about 500 freezing cycles!

The use of a special type of clay requires a lot of investment to find places of deposits of raw materials.The process itself is also quite complicated and financially costly. This is the reason for the high cost of clinker.

If it is impossible to use expensive clinker, you can install more affordable clinker tiles. Another worthy analogue is brick-like concrete tiles.

Silicate

The basis of the composition of silicate bricks is quartz sand. Lime, modifiers and plasticizers, pigment are added to it. The production of products is carried out by the method of autoclave synthesis. At the first stage, the shape of the future product is given by dry pressing. Then the workpiece is exposed to water vapor, the temperature of which is 170-200 degrees, and high pressure - up to 12 atmospheres.

Silicate brick demonstrates high strength, good heat and sound insulation qualities, and also has an accurate shape and an affordable price.

However, for cladding a building, the material is rarely used due to its high moisture absorption and high weight. In cases where silicate bricks are nevertheless chosen for cladding, the masonry must be treated with water repellents, as well as the roof plumb lines must be increased to better protect the facade.

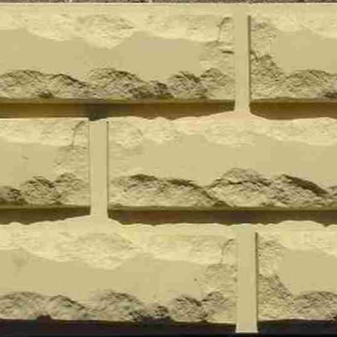

Hyperpressed

A relatively new product on the construction market. The surface of the brick is an imitation of natural stone chips. At the same time, the material is lightweight and affordable. This is explained by the fact that the cement slurry is no more than 10-15%, all other components are waste from sawing natural stone (ground into crumbs), rejection from stone and crushed stone, sandy shell rock, etc.

All components are mixed, moistened and sent to molds, where they are pressed under enormous pressure. The final stage of production is drying or steaming the products.

One of the highlights is the incredible dimensional accuracy. Possible deviations do not exceed 0.5 mm. This is very valuable when laying a brick facade and unattainable when making clinker or ceramic bricks.

Flexible

It is not a type of brick in the full sense, rather, it is a soft mineral-polymer panel with imitation of clinker masonry. Unlike the types discussed above, the material does not require strengthening the foundation, it will allow you to revet the facade faster and cheaper.

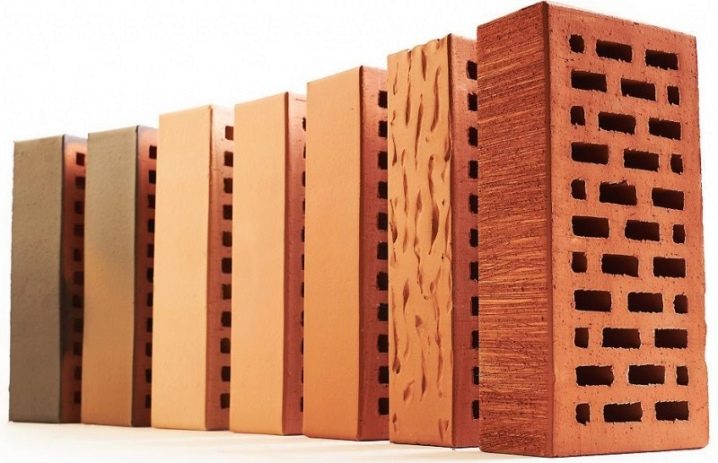

Design

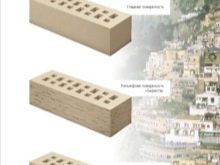

Differences between products can be based not only on the material of manufacture, but also depend on the features of the texture of the brick. Bricks of the following textures are distinguished.

Smooth

The most affordable and easy to manufacture type of brick. It is worth noting the convenience and ease of use - dirt does not accumulate on a smooth surface, ice does not form, a layer of snow does not stick.

Embossed

They have artistic grooves and protrusions that form a decorative pattern. As a rule, they are used for finishing individual elements of the facade - window openings, architectural components. It is irrational to use it on the entire surface of the wall, since the embossed surface retains dust, becomes covered with ice.

It is also good to know that the relief is invisible from a distance, but it provides an interesting color effect. Refracting against heterogeneous surfaces, the sun's rays illuminate the facade in different ways. As a result, he plays with different colors, shimmers.

Glazed

These bricks come in different colors, sometimes completely incredible. A similar effect is achieved by applying special clay compositions or a layer of colored glass chips to the brick surface. Further, the brick is fired at a temperature of no more than 700 degrees. This causes the top layer to melt and sinter with the main body. When using clay, a painted matte brick is obtained, when a glass layer is applied - an elegant glossy analogue.

Engobed

Externally, engobed bricks do not differ from glazed ones - they also have different colors, matte or glossy surfaces. However, the weight of the former is less, as is its price.This is due to the fact that the brick is fired not 2 times, but one, which reduces its cost. The dye is applied to the dried product and only after that it is fired.

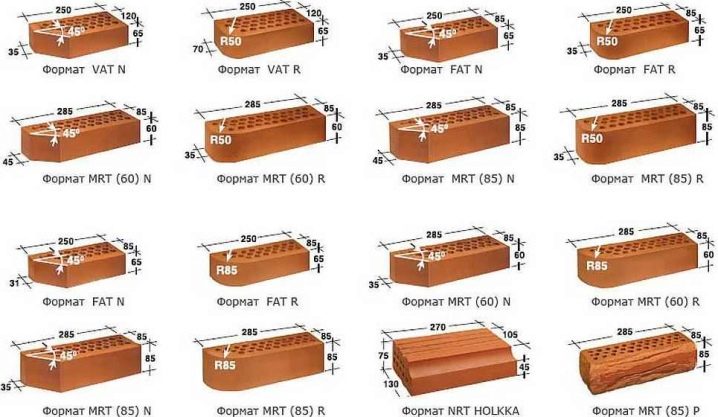

Dimensions (edit)

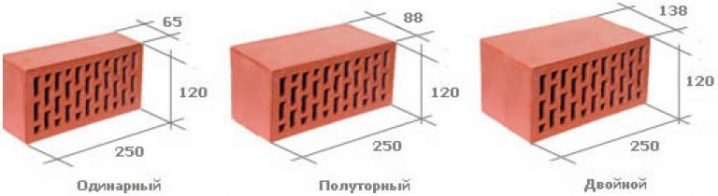

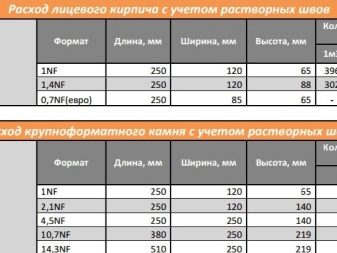

For a long time, the only type of brick in terms of dimensions existed on the domestic market. It can still be found on sale today. Standard brick sizes are 250 * 120 * 65 mm. This size is designated as 1NF and is called single (KO).

If we talk about other types of bricks of domestic production, then the following are distinguished:

- Euro (KE) - has a smaller width compared to a single analogue, therefore, by size type, it is 0.7 NF. Its dimensions are 250 * 85 * 65 mm.

- Single modular (KM) has dimensions of 288 * 138 * 65 mm, and its size is indicated as 1.3 NF.

- Thickened brick (KU) - this is a thicker variety of standard bricks, in the product it is 88 mm, size type is 1.4 NF. In addition, there is a modification of the thickened brick with horizontal voids (CUG).

- Stone (K) - includes several types of bricks, the length of which is 250 or 288 mm, the width varies from 120 to 288 mm, the height is 88 or 140 mm.

- Large-format stone (QC) also includes several types of products, the minimum width of which is 220 mm, the maximum width is 510 mm. The width is presented in 3 options - 180, 250 or 255 mm. The height ranges from 70 to 219 mm. A kind of large-format stone is an analogue with horizontal voids (CCG).

You can find out about the features of the sizes by looking at the accompanying documents of the products. In addition to those indicated, it is important to know the decoding of such designations as P - ordinary brick, L - front or front, Po - solid, Pu - hollow.

The standard description of products looks like this - KOLPo 1 NF / 100 / 2.0 / 50 / GOST 530-2007. At first glance, this is a meaningless set of characters. However, being able to "read" the designations, it is easy to understand that we have before us a single front brick with a strength grade M100, the average density class of the product is 2.0, and the frost resistance is 50 freeze / thaw cycles. The product complies with a certain GOST.

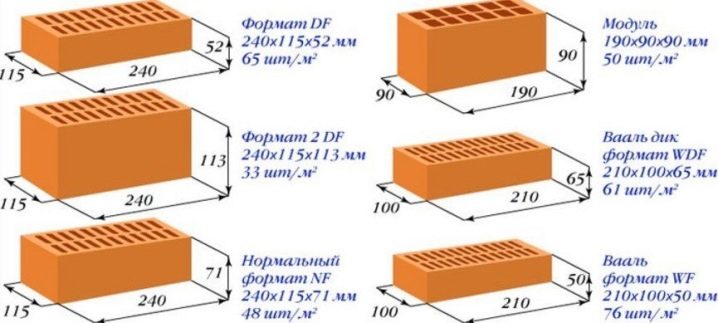

For imported bricks, different conventions are used, since they have different dimensions. Let's consider the most popular options:

- Wf - in this way bricks with a size of 210 * 100 * 50 mm are marked;

- OF - products of a slightly larger format - 220 * 105 * 52 mm;

- DF - an even larger type of product with dimensions of 240 * 115 * 52 mm;

- WDF the model is characterized by dimensions of 210 * 100 * 65 mm;

- 2-DF - a larger analogue of DF, measuring 240 * 115 * 113 mm.

These are far from all the possible dimensions of the finishing material. Moreover, most manufacturers have their own size charts and use the original markings. Finally, there are hand-molded bricks that do not come in standard sizes.

In connection with such a dimensional variety, you should start calculating the required amount of bricks and purchasing it only after you have precisely decided on the type of product used and clarified its dimensions with the supplier.

Manufacturers overview

Ceramic bricks are most widely used for cladding, since they have an optimal price / quality ratio. Consider the most worthy brands of ceramic bricks.

Braer

The material of domestic production is a standard facing hollow brick imitating the texture of oak bark. Strength indicators - M 150, moisture resistance indicators are average for this type of material - 9%. There are collections that imitate the antique analogue, as well as bricks with textures "rustic", "oak bark", "water surface". Even within the same batch, the bricks have different shades, which makes Bavarian masonry possible.

LSR

Another Russian brand that produces eurobricks with a “white rustic” texture. These hollow bodies have increased strength (M175) and slightly lower moisture absorption (6-9%).The advantage is a rather varied design - "rustic", "water strokes" and "wave", "antique brick" and "birch bark".

Wienerberger

The products of the Estonian factory Aseri, which are also hollow ceramic bricks, corresponding to the size of the euro. Unlike domestic counterparts, it has a significantly higher strength (M300). Moisture absorption indicators - no more than 9%. This brick looks softer and more airy due to its creamy shade.

Tiileri

Finnish red hollow brick, which also has improved strength characteristics (M300) and better moisture absorption (8%). Available in a single version with a smooth surface.

Nelissen

Solid brick of Belgian origin with strength indicators M250 and moisture absorption 15%. It is produced in gray color, various relief textures are possible.

The second most popular place is occupied by clinker facade bricks. Among the most reputable manufacturers are the following.

Domestic companies "Ekoklinker" and "Terbunsky potter"

Standard hollow bricks are produced. The strength of the "Ecolinker" bricks is M300, which is 2 times higher than the strength of bricks from the second manufacturer. Differences in the values of moisture absorption are insignificant (5-6%). The bricks of both brands have the same smooth surface, the only difference is in color. Ekolinker products have a pleasant chocolate shade; the Terbunsky Potter bricks are characterized by a beige palette.

"Naples"

The clinker of this domestic manufacturer is presented in the European size and is a smooth white hollow brick with moisture resistance indicators of no more than 6%. It has 2 modifications - products with strength indicators M200 and M300.

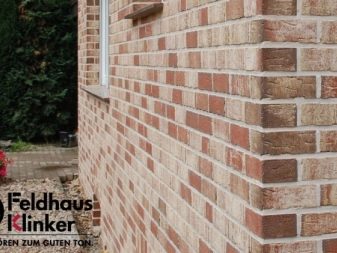

German companies Hagemeister and Feldhaus Klinker

The products of these manufacturers are united by the same high strength indicators (M1000). The products of both brands are hollow ceramic bricks with a smooth surface. The moisture absorption of Hagemeister products is 2.9%, Feldhaus Klinker - from 2 to 4%. The color palette of the latter is shades of red, while Hagemeister bricks are characterized by a gray palette.

German brands Janinhoff and ABC

It also combines the similarity of strength characteristics (M400) and moisture absorption indicators (3-4%). The products of both companies are smooth hollow bricks. ABC produces yellow and yellow-coal products, the second manufacturer produces red and brown-red counterparts.

High-quality hyper-pressed brick can be found in the catalogs of the domestic manufacturer Avangard. There are several collections at the buyer's choice, in which products differ in color, texture features. As for the size, this is a standard brick, as well as its analogue, which is 2 times smaller in width (that is, 60 cm). Among the significant characteristics - M250, water absorption of the material - 6.3%.

How to choose?

In addition to bricks, consultants usually offer to purchase curly elements for decorating bevels, door and window openings, corners and other architectural elements. Such structures have a curly shape and are much more expensive than bricks for outdoor decoration.

It makes sense to acquire them if you intend to carry out the facing work with your own hands, and you do not have the professional skills for this. Using curly elements will greatly facilitate the process.

If the cladding is carried out by a professional, then he will be able to attractively arrange the corners and other elements of the facade even without the use of curly structures. This type of work will cost more than a simple brick laying on a flat surface. However, even in this case, the cost of the work of the wizard in the design of complex elements will be lower in comparison with the cost of purchasing curly products.

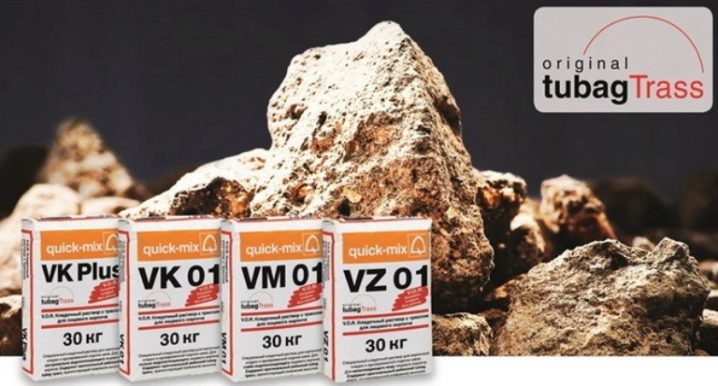

In addition to bricks, you should take care of buying a mortar. Today, less and less water-based cement-sand mortar is used due to the decrease in water absorption rates of modern bricks.

So, the moisture absorption of clinker can be as low as 3%, therefore, when using traditional cement mortar, it is simply not possible to achieve high-quality adhesion.

The construction market offers a wide variety of masonry mortars. It is important to select a composition that matches the type of brick used. The fixing mixes V. O. R are trusted by customers. The range includes mortars for clinker and other types of bricks. Conveniently, the same solutions can also be used for external finishing of seams.

Solutions from manufacturers usually have a rich color palette. You can choose the option that is as close as possible in color to the shade of the bricks, or choose a more contrasting combination.

Calculations

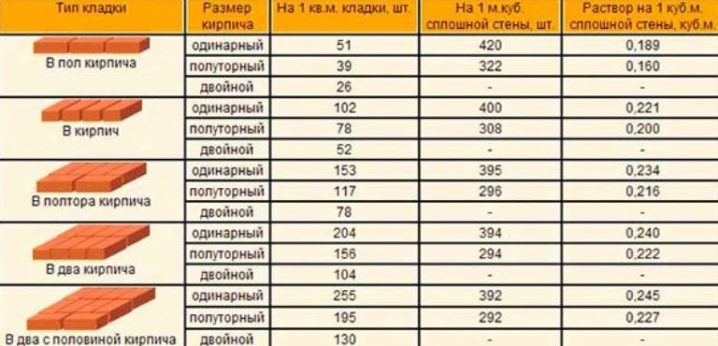

When creating brick facades, the finishing material is usually laid with a spoon. If you lay the material with a jab, it significantly increases its consumption.

The buyer does not need to calculate the amount of material taking into account the bonded cladding, since the bricks are still purchased with a margin of 25-30%. The resulting amount is enough even if necessary, sometimes lay the cladding with a poke.

The number of products directly depends on the area of the facade and the thickness of the seams. The larger the latter, the less brick is needed to finish 1 m2. A joint thickness of 10 mm is considered standard, but this value may vary depending on the characteristics of the brick and the skill of the bricklayer. Real virtuosos are able to create masonry with a thickness of 8 mm between bricks.

When calculating the volume of material, it is important to take into account the width of the row. So, when laying in one brick, finishing two-story buildings may require as much material as one-story facades when finishing one and a half or two bricks.

Material tips

Achieving the strength, durability and visual appeal of a brick facade is possible only when working in strict accordance with existing technologies:

- Brick cladding is always a ventilated facade. It is better to use "breathing" mineral wool as a heater (if necessary). The use of polyurethane foam and polystyrene foam sheets is impractical, since in this case they cannot be avoided dampness, which means that the materials will lose their heat-insulating properties. Their use is permissible only in the absence of a ventilation gap between the facade and the walls.

- The service life of mineral wool insulation can be increased by using a moisture-proof vapor-permeable membrane.

- Brick cladding, especially a combined facade (when different materials are used for the walls and facade part), requires binding with load-bearing walls. Outdated "old-fashioned" communication methods (reinforcement, steel mesh and other materials at hand) usually cause the facade to crack in the bonding area.

It is preferable to use galvanized wire or perforated and flexible stainless steel strips, as well as basalt-plastic flexible rods for work.

- If it is necessary to cut bricks, the only tool that will allow you to make an even cut without destroying the material is a grinder with a disc for cutting dry stone with a diameter of 230 mm.

- Before laying the facade, the load-bearing walls must be cleaned, dried and covered with at least two coats of primer, and wooden structures require additional treatment with antiseptics and fire retardants.

- The use of products from several batches at once will help to avoid the effect of a striped facade, the appearance of which is due to differences in brick shades. To do this, take 3-5 pallets with bricks from different lots and use them one by one when laying the rows.

- When using not special masonry mixtures, but self-made cement mortar, the bricks are soaked in water for several minutes before laying. This is to prevent the material from picking up moisture from the solution.

- It is important to make vertical ventilation gaps every 3 rows of cladding. They are not filled with a solution; when it gets there, it is immediately removed with a wooden stick. You can also arrange ventilation gaps using plastic boxes. Their width is 10 mm and their height corresponds to the height of the brick. Their use is much more convenient, especially since the boxes are inexpensive.

- At least 2 ventilation gaps must remain in the lower part of the windows during cladding.

- Brick laying can be carried out only at a positive air temperature in dry weather.

It is important to immediately remove excess mortar that has fallen on the front side of the masonry. After completing each row, it is recommended to brush off drops of solution from the front side with a brush.

Spectacular examples in the exterior

Facing houses with bricks can be performed on the entire surface of the facade or only part of it. Variants of combined facades can be represented by a combination of brick and plaster, wood.

Of course, a combination of noble clinker and wood is a win-win, for example, as in the design of this open veranda.

Beautiful facades are obtained when using bricks with a pattern or a combination of monochrome and variegated products (some imported bricks within the same batch have, for example, red and red variegated bricks). As a result, the masonry turns out to be voluminous, a mosaic effect arises.

The exteriors of private cottages look refined and stylish, where the elements of the facade are continued when decorating neighboring buildings, garden paths, and entrance groups.

For classic-style houses, the combination of stone and brickwork, as well as the use of antique bricks, is relevant.

It is also important what the shade of the house will be from the outside. A combination of two or more shades allows to avoid monotony and add volume to the facade. A classic technique can be called a technique in which the brickwork is performed in beige shades, and the window openings have a darker, contrasting solution.

If you wish, you can paint the brick facade, waiting for it to dry completely and treating the surface with a 10% chlorine solution (to remove traces of the solution on the front of the brick). The chosen shade can be any, but the most common is black and white, beige.

See below for more details.

The comment was sent successfully.