Sheathing the facade of the house with OSB-plates

Facing the structure with OSB-plates increases its service life, creates an optimal level of comfort inside the building. From the material of this article, you will learn how to sheathe the facade of a house with OSB-plates, what are the features of the technology with your own hands - from the choice of materials to sealing the seams.

Peculiarities

Oriented strand boards are a popular material in construction with high technical characteristics. The products are wood chipboards made of thin chips glued with waterproof resins in 3 layers. Their strength is greater than chipboard, they are easy to work with and are inexpensive. They are classic and laminated.

The construction method using OSB-plates, carried out according to Canadian technology, is a classic. The essence of the technique is to fix the plates to the frame racks. The structure is designed specifically for this material. The dimensions of the panels are taken into account in order to fasten them to the racks with joints.

This ensures a reliable connection of the slabs to the frame. Experienced specialists try to sheathe the frame so that the sheets are cut as little as possible. Openings and holes on the slabs are made using special tools.

Construction tape is also used in the work. They are sealed with fasteners at the junction of the panels.

Tools and materials

Before proceeding directly to work, you need to decide on the facing material. There are 4 types of OSB boards.

- OSB 1 belongs to the varieties with the lowest mechanical strength. They are not suitable for load-bearing wall cladding.

- OSB 2 is a little stronger, but they can sheathe walls or ceilings only inside dry rooms.

- You can sheathe the facade of the house with OSB-plates of 3 types. The material is suitable for cladding indoors and outdoors (verandas in the country, panel, wooden houses from a bar, baths).

- OSB 4 is a building material with the highest resistance to moisture and significant mechanical stress.

It is better to sheathe the facade of OSB 4. However, if it is necessary to minimize costs, it is worth choosing OSB-3 panels, which are considered conditionally universal.

The best option for external walls is a material with large dimensions. With it, work is accelerated, the number of joints is reduced, it is easier to achieve accuracy of technological gaps, flatness of planes without drops and ledges.

The thickness of the panels for the external cladding of the frame house should be 11-13 mm. These are optimal values: if it is less than 1 cm, there should be additional jibs in the frame. However, when choosing a material, the type of structure is also taken into account:

- for one-story buildings, it is better to choose 11 mm thick slabs;

- for cladding 2 and 3-storey houses, sheets with a thickness of 12.5 mm are needed.

Plates with a greater thickness are used for the construction of interfloor ceilings. If you need to sheathe the facade of a temporary building for seasonal living, they buy slabs less than 11 mm thick.

When choosing a slab, the distance between the frame posts is taken into account. An interval of 40 cm implies the purchase of a sheathing material with a thickness of at least 9 mm. If the step is 60 cm, take OSB with a thickness of 1.2 cm.With an interval of 80 cm, you need to choose a thicker material.

Calculating the required number of sheets for the exterior of the house, find the area of the walls. To do this, multiply their indicators of height and width. From the resulting number, subtract the area of each opening, which is not subject to sheathing.

To calculate the number of blocks required, divide the cladding area by the area of one block. The area of the leaf is found by multiplying the length and height. As for the tools, the following will come in handy in the work:

- hacksaw;

- construction tape;

- simple pencil;

- building level;

- hammer;

- plumb line;

- jigsaw (circular saw).

In addition, you may need a grinder, drill, screwdriver, a set of screwdrivers.

If a concrete structure is sheathed with slabs, the base is initially prepared. To do this, get rid of the old decorative coating, protruding objects. They carry out the transfer of existing communication systems, clean the base from dust and dirt.

After that, they are engaged in joining the cracks, priming them and covering them up. If mold is visible on the base, special treatment is carried out. Strengthen damaged areas, strengthen the foundation if necessary. Next, the base is dried, the frame is erected and the insulation is laid.

Fastening of blocks to a timber frame can be done in two ways - to wooden structural elements or to a prepared crate. Working according to the first method allows you to achieve maximum wall stiffness. At the same time, a skeleton of the frame is created, chip blocks are mounted on it.

After that, an insulating membrane is pulled onto the slabs, a ventilation gap is built, then they are finished. The second type of work is more common in view of saving time and minimizing financial costs.

Installation of the lathing

The lathing is assembled from thin slats or small-sized bars. At the same time, it is important to correctly install the beams themselves, to make accurate markings.

Markup

The lathing marking is a preparatory stage that determines the quality of the entire structure. It can be done using a laser level, controlling the position of the lines on all walls relative to the horizontal. If not, use a water level.

The level of location of the ceiling plane is selected. Then, from below in the corner, a point is marked at the level, taking into account that the plane will be lower (by the thickness of the cladding). Using the hydro level, this point is transferred to all the remaining corners of the room.

Next, the horizontal lines are marked on the walls, later - the fixation points of the suspension mounts so that the joints of the fixed sheets fall on the supporting rails or profiles. After the markup is completed, they begin to assemble the frame under the OSB.

The lathing for OSB is made of wood and metal profiles. It is best to use a wooden bar in your work. It is attached to the base in one plane. Before installation, it is dried, covered with protective compounds and dried.

Insulation

Insulation of the structure is performed after the creation of the lathing. The material selected as insulation is placed on the glue in the formed cells (without a gap). If necessary, it is fixed with special dowels.

Mineral wool can be used as insulation. Before laying the material, the length of the fasteners is calculated so that the holders protrude 4-5 cm above the surface of the insulating layer; the ends of the holders pierce the insulation layer.

Insulation with a moisture-proof membrane is performed after laying the insulation. This is necessary so that the insulating layer of the frame cake does not damp and does not absorb moisture from the surrounding air.

Wind and moisture protection isospan can be used as a material. Someone uses plastic wrap as a membrane.

Fastening the guide bars

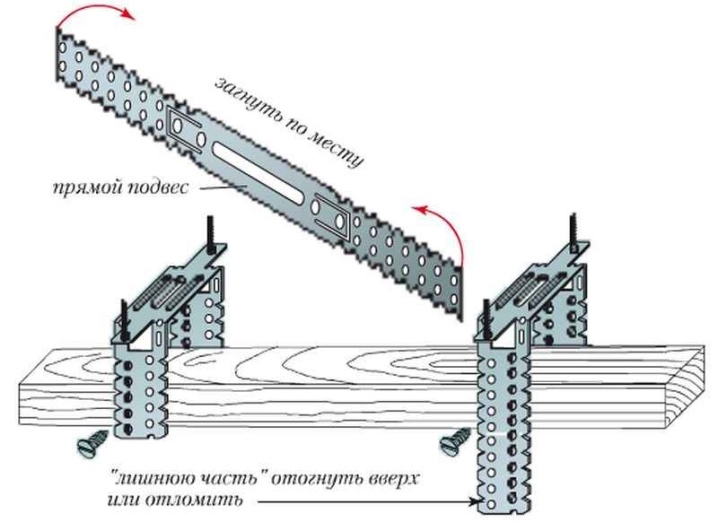

The bars are attached to the wall with hangers. Before they are fixed, vertical stripes are drawn on the wall ceilings with an interval of half the width of the block. In the future, this will ensure the joining of the OSB in the middle of the bar and will allow the sheet to be fixed in the center along the entire length. The suspensions are fixed along the drawn lines with an interval of 0.3-0.4 m.

How to fix the slabs?

The sheet material must be secured with the right side out. It is not difficult to correctly determine the right side: the fragments of chips on it are larger than on the seamy side of the sheet. OSB is attached to frame racks with self-tapping screws or spiral nails (you can combine both types of fasteners).

When sheathing the facade of a one-story building with thin panels (0.9 cm thick), the blocks are mounted horizontally. This method is considered by the masters to be the best, since this results in a larger number of racks. Vertical finishing is performed for tall buildings.

The first slab is fixed from the corner of the building with the formation of a 1 cm gap from the foundation. To simplify the work, substrates are placed around the entire perimeter of the sheathing. Adjacent slabs are attached from the outside with a gap of 0.2-0.4 cm. All edges must fall on the frame posts.

When the bottom row is laid, lay the next one with an offset of one step between the uprights. Fragments of adjacent sections of the wall are nailed in such a way that a straight joint is formed.

The heads of nails or screws are flush. They should not complicate the finish.

Gable trim tips

In order to beautifully and correctly sheathe the gable of the house, immediately before installing the panels, it is necessary to install racks on the gables with a distance of 125 cm (across the width of the sheet). For the rack, you need to take a board with a section of 5x10 cm. The racks are fixed with nails from the outside.

The outer sheets of OSB must be counted from the point of contact of the frontal board of the attic floor, as well as the rafters of the roof (so that the slab covers the pediment completely). The algorithm for installing the pediment is as follows:

- measure the height of the racks along the edges of this opening;

- transfer the dimensions to the OSB panel;

- cut the sheet to size with a hand-held circular saw;

- screw on handles for easy transfer of the sheet;

- fix a metal corner to rest on the frontal board;

- screw in self-tapping screws along the contour of the sheet (without a protrusion on the back side);

- lift the sheet, fix it with clamps;

- screw the self-tapping screws.

Sealing of seams

Sealing is done with an acrylic resin sealant. They are used to seal the joints of seams, cracks, gaps. As the main raw material, you can use an elastic wood filler intended for outdoor use.

A homemade solution of sawdust and PVA glue is also suitable, but in this case, the joints will have to be masked with slats or special overlays.

In addition, you can use a special sealing compound "Warm seam".

Sheathing the facade of the house with OSB-plates in the video.

The comment was sent successfully.