Selection criteria for plinth panels

The cladding of the house has always been an important stage in the arrangement of the entire building. These works are also necessary for the basement of the building, since it is he who needs special protection from the effects of external factors, and also the decorative component of this process, which depends on the chosen material for decoration, will be an important factor.

Peculiarities

For the exterior design of the facades of city buildings and country houses, they generally prefer to use basement panels, although there are many options for performing such a finish, for example, when using artificial or natural stone, brick, plaster, or painting the base.

The demand for panels is due to the specific features of the product. The products have high quality characteristics, time-tested, therefore, the panels are purchased for cladding the basement, building fronts, or are used as facade wall products.

Due to its visual appeal, the products will decorate and transform the building, at the same time increasing the energy-saving properties of the foundations of the house, and also extend the service life of the materials that were used to insulate the building.

In fact, the panels are basement siding, which is produced from different materials, based on which the products can be divided into types.

It is worth noting the positive features of the basement panels:

- The manufacturing technology of products involves the use of various additives, thanks to which the products become waterproof, resistant to high humidity, low and high temperatures.

- The advantage of panels imitating stone finish is the fact that moss does not grow between products over time, and mold does not form at the joints, unlike, for example, granite.

- Siding retains its original shape and color for a very long time, since it is not prone to deformation from dampness, which sometimes spoils the material, since it is located close to the foundation, and it also does not fade from ultraviolet radiation.

- The service life of decorative plinth panels is about 50 years.

- Installation of products to a reinforced concrete base can be carried out even in severe frost, reaching a revenge of -45C.

- All elements that make up the product are harmless to human health, they are odorless and do not evaporate toxic substances.

- The panels are characterized by high strength values.

- Products are more affordable than wood or natural stone.

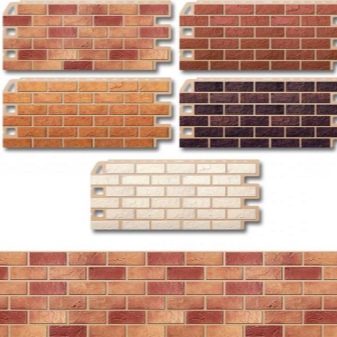

- A variety of siding textures allows you to choose products for finishing the basement, which will imitate finishing with brickwork, stone, wood. Thanks to modern technologies, manufacturers produce a product that looks very similar to a natural expensive material.

- Installation of panels does not require serious labor, so the installation of the material can be done by hand.

- In addition to the fact that the products are resistant to the development of microorganisms on the surface and joints, they protect the bases from the penetration of insects.

- The panels provide good drainage for condensation, therefore, the protection of the walls from dampness and freezing increases.

To form an objective opinion about the product, it is necessary to note the shortcomings of the material:

- During the installation of products on concrete products in violation of the instructions, when no gaps are left for linear expansion of products, the panel may crack.

- Some species will melt when exposed to critically high temperatures, such as in a fire. However, this disadvantage can also be attributed to the advantages of the product, since the panels will not act as a source of fire.

Views

Plinth panels are the face of the sandwich, which provides the home with the necessary level of insulation and aesthetic appeal. The products comply with the SNiP standards, in which the indicators of thermal and sound protection of private structures and general buildings are prescribed.

The most popular are two types of panels, differing in texture:

- Products that imitate brickwork. This variety is in demand for suburban buildings.

- Panels made to look like a stone.

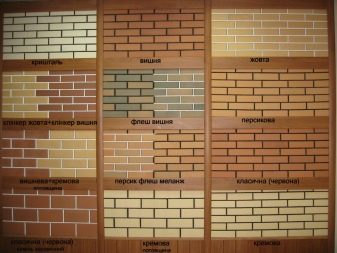

Products are presented in a wide variety of shades and structures, therefore, it allows you to choose the most suitable option for a particular building facade. The products are additionally completed with fastening elements.

Based on the material used for the manufacture of basement panels, products can be classified as follows:

Fiber cement panels

These products are sold at the highest cost, unlike other varieties, regardless of the type of texture. According to the specifics of manufacturing, fiber cement refers to a type of concrete with the inclusion of special substances that provide a higher level of practical and aesthetic properties of products. Basically, these components are produced from quartz sand and cellulose.

The positive features of the product include:

- resistance to temperature extremes (raw materials do not lose their properties at temperatures from +600 to -500 C);

- incombustibility of fiber cement panels;

- no influence on the quality of the level of pollution or increased salt content in the environment where the panels will be used;

- do not allow moisture to pass through, provided that the joints are securely sealed;

- long service life;

- high level of product durability.

Among the disadvantages of fiber cement basement panels, the fragility of the products stands out, so the products require careful transportation. In addition, the products are not repairable.

Metal siding

Such products have been sold on the construction market not so long ago. However, the scope of its application allows the use of products for facing the foundation, as well as for finishing the entire building.

Among the advantages of this material, it is necessary to highlight the following properties:

- High level of protection for the building from atmospheric agents. This characteristic is due to the presence of a special polymer layer on the surface of the panels.

- A variety of textures - in addition to the above options, the panels can be decorated with a variety of photo printing.

- Ease of installation - installation can be done independently, using the base leg as a junction unit.

- The products are allowed to be used for buildings located on sloping areas, in contrast to fiber cement panels.

The disadvantages of such products include a rather laborious installation, when it is supposed to use large panels - about 3 meters. However, such a drawback is easy to solve when buying additional elements, due to which you can use not one six-meter product, but three parts of two meters each.

Acrylic PVC Panels

The versatility of texture and a large selection of color solutions allowed the products to take a leading position in terms of the number of purchased products, in comparison with other varieties.

The following characteristics are considered to be the advantages of the products:

- the ability to fix panels with your own hands;

- reliability of parts for fastening (most often, finishing strips are used for fixing, which are distinguished by their external attractiveness and are in perfect harmony with the rest of the design of the facade of the building);

- long service life, which depends on the manufacturer of the panels, as well as the thickness of the products.

Experts do not notice any significant shortcomings of the products. However, it is worth highlighting the specifics of the crate - it must be thick enough. When buying products, you should give preference only to trusted manufacturers and avoid purchasing fakes. Otherwise, the panels may become deformed and discolored during operation.

Vinyl products visually differ little from the above-described products made of polyvinyl chloride. But the technical properties of vinyl products are several times lower. The only advantage of such panels is their low cost.

Clinker thermal panels

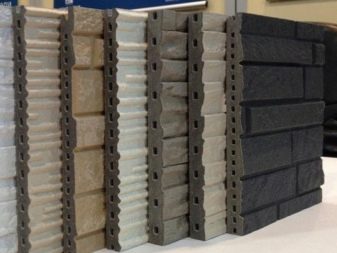

These products are made on the basis of insulation. Due to the specific composition of the product, they provide an additional level of warming of the bases, as well as an attractive appearance for the base. Brick products for brick are made from varieties of expanded polystyrene, there are three-layer products made of polyurethane foam.

The products have a specific shape and dimensions, due to which the docked products form an integral composition with minimally distinguishable joints. The products are presented in a variety of colors, but at a cost they are much more expensive than PVC panels.

Thermal panels for stone

The production is carried out according to a similar scheme as clinker products for finishing the basement. However, in this case, the role of a finishing element is not tile, but porcelain stoneware, due to which the products belong to the category of expensive panels.

Mounting

The cladding of the building basement can only be carried out after the foundation has shrunk. This applies to all types of its arrangement. This usually takes 6 to 12 months.

The panels can be fastened in two ways:

- In the first version, the fasteners involve the use of special locks, which are located on the end part of the facing elements. There is a hook at the bottom of the panel, and a counterpart on the top. Such fixation is characterized by a high level of reliability. Experts recommend mounting from below, gradually going up.

- The second method of installation is carried out on the pins located at the bottom of each product. At the top of the elements, special holes are made for them. This installation method assumes that the work will be carried out in the reverse order.

To save on the plinth cladding, you can carry out the work without the participation of specialists. The production and configuration of panels allows you to carry out these works yourself. For installation, you will need the following tools: a level, milk and nails, self-tapping screws, a hacksaw and a metal saw, construction gloves and goggles.

To do the cladding with your own hands, first of all, you need to study the design of the basement panels.

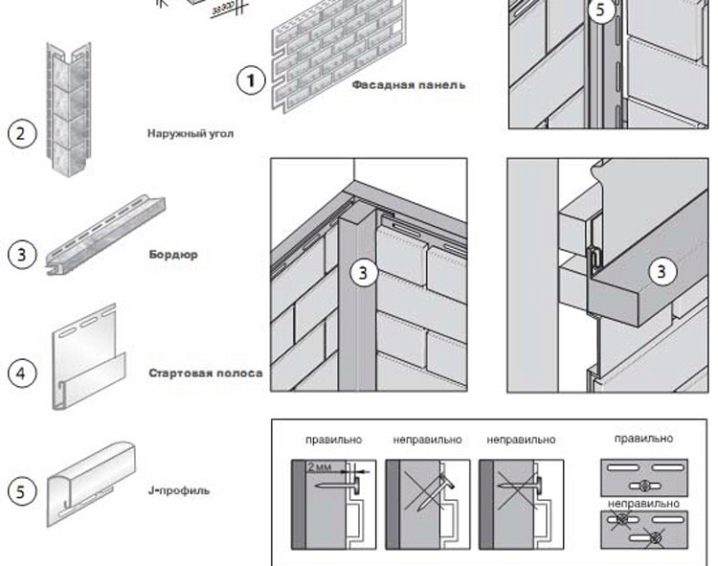

The main components required for the installation of products:

- starting strip and J-profile;

- outer and inner corner;

- fitting profile;

- H-profile.

Panel fastening technology involves the following works:

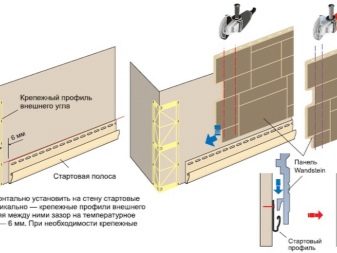

- First, the lathing is performed, which will provide a flat base surface. This indicator is fundamental, since it guarantees reliable installation and fixation of the panels. The construction of the structure requires the use of metal or wood planks, they can be homemade.

- Next, the starting profile is attached. It should be 10 centimeters away from the corner of the house. Its fixation is done with nails. The correct position of the plank can be easily checked with a spirit level.

- Then, based on the measurements of the base, you should start cutting the material.It is important to remember that the edge panel must be at least 30 cm long.

- All work on the installation of basement panels should be started from the left side of the building. The first element is installed, it is shifted to the maximum left. Then, using a sealant, the part is docked with the corner of the house.

- Having laid the bottom row, you can continue to work with the next row of elements.

- After laying all the panels, you need to install the outer corners, after which the upper edge of the last row of panels is closed with a special board.

Manufacturers

In the modern market, the following companies are popular that are engaged in the production of basement panels: Novik, VOX, Docke, Alta-Profil.

Novik brand products stands out for products made under the stone, the panels have a low cost. Talc is present in the composition of the polymers used for the manufacture of products.

Firm VOX produces the thinnest products for plinth cladding, imitating brickwork.

For the release of Docke panels the casting technology is used, so the products have a short operational life.

Panels "Alta-Profile" presented on the market as products with the largest thickness, which affects the cost of facing products.

Advice

In order to avoid mistakes in the selection of building material, you need to follow the recommendations:

- Pay special attention to the joints of the products. The panels should fit as tightly as possible to each other. The presence of gaps will indicate that the material is made in violation of production technologies, which will negatively affect its quality.

- It is worth knowing that the strength index of products is not determined by the hardness of the material.

- Basement panels are a narrow-profile material, therefore, the entire facade of the house cannot be clad with them.

- For fastening the elements, it is better to purchase high-quality consumables, therefore, nails and screws for work must be made of stainless steel.

For the installation of Wandstein basement panels, see the video below.

The comment was sent successfully.