Facade panels for exterior decoration of the house: types and methods of installation

Today, an increasing number of owners of suburban real estate, when finishing, prefer a relatively new material - facade panels. This coating is capable of imitating natural materials, which means visual appeal, but at the same time it is much cheaper and has better technical characteristics. The panels are easy to install, they protect the house from various external influences and are able to serve for a sufficient period of time. In addition, façade panels are extremely easy to maintain.

Peculiarities

Facade panels are mounted both on the walls and on the frame if it is necessary to create a ventilated facade. Usually, materials are supplied with detailed instructions from the manufacturers, which explain what is installed and in what order, and how, in general, the building is finished.

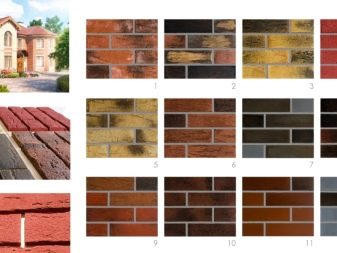

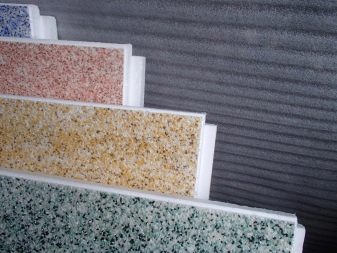

The panels are realized in various colors and textures, which allows customers to design the facade in accordance with any desires. They not only create the appearance of the building, but also endow it with additional functions: insulation, noise protection, and others. As a rule, all panels qualitatively protect the structure from temperature fluctuations, gusts of wind, rain and other weather "troubles".

Specifications

Cladding panels used for finishing the facade of a house must fully meet the requirements of GOST, regardless of manufacturers. They can consist of several layers, be with a homogeneous or combined structure., with or without insulation.

The thickness of the metal panels is approximately 0.5 millimeters. The weight of steel panels is 9 kilograms per square meter, and the weight of aluminum panels is 7 kilograms per square meter. The panels are covered with a protective layer of polymers and do not allow moisture to pass through. The thermal conductivity of the metal is 40.9 W / (m * K), which is considered a rather bad indicator. In addition, such panels create certain interference with electromagnetic waves, which is quite specific, but still a plus.

Wood fiber panels are absolutely harmless to humans and the environment. They save heat and energy and are twice as effective against frost as metal panels. The density of the material is quite high, which protects it from deformation and cracking.

Vinyl panels weigh about 5 kilograms per square meter. They do not allow moisture to pass through, do not rot, do not corrode and save heat in the room. Panels based on polyurethane foam weigh about the same and have the same low thermal conductivity. During a fire, they are able to stop the spread of the flame. They have high moisture resistance and are used to decorate surfaces of "uncomfortable" shape.

The thickness of fiber cement panels reaches 15 millimeters, and the weight is more than 16 kilograms per square meter. They are not afraid of ultraviolet radiation, as they contain components that act as a filter for ultraviolet rays.

Natural stone panels can weigh up to 64 kilograms per square meter. They are frost resistant and exhibit a water absorption rate of 0.07%.

All of the above panels are considered ventilated, capable of being used for a long time and withstanding significant temperature fluctuations.

Advantages and disadvantages

At first glance, facade panels have only advantages:

- they are able to protect the home from rains, snowfalls and other weather manifestations;

- they do not corrode and are not adversely affected by ultraviolet light;

- they do not depend on temperature fluctuations and function equally well in frost and heat;

- the installation process is very simple, does not require special preparation or wall treatment;

- fasteners are also simple and affordable;

- can be installed both vertically and horizontally;

- have a wide number of colors and imitation of natural materials;

- easily fit into any design solutions;

- have an affordable price;

- installation can be carried out at any time of the year;

- corrosion-resistant, especially natural stone options;

- they are easy to care for;

- all typical sizes are available;

- most varieties are non-flammable.

The only drawbacks are the fact that some types of panels are still very expensive (for example, natural stone), and specialists will have to be involved to carry out the work.

Variety of materials

Facade panels are made from both natural and synthetic materials. They differ in a variety of textures, shades and design solutions. It is important to choose the right material not only because the appearance of the house will depend on it, but also because the material will protect the structure from atmospheric troubles.

Composite

There is a large selection of composite finishing panels. One of them is fiber cement. Such a panel is made on the basis of cement and consists almost entirely of ordinary plaster. The panels are covered with a protective layer on both sides. In addition, in the composition you can find special granules that regulate the intake and return of moisture when the weather changes and other impurities. Typically 90% cement and mineral fibers and 10% plastic and cellulose fibers. The fibers are randomly arranged, so they give strength to bends.

The material has very decent technical characteristics: high sound insulation, moisture resistance and frost resistance. It should be added that it is also fireproof and environmentally friendly.

Fiber cement is often used in buildings that need to be protected from excessive noise, such as in homes near the airport or even indoors. Installation of fiber cement panels is easy and can be done independently.

Cement panels of any color and shape of interest are available in stores. They imitate wood plank, marble, stone and other materials. However, if you want to repaint them in some unusual color, you will have to pay a significant amount. Typically acrylic and polyurethane paints are used on pre-treated surfaces. Also, the disadvantage of these panels is considered to be active absorption of moisture, which does not affect the strength, but slightly spoils the appearance. But fiber cement slabs are covered with a special hydrophilic film, with which the surface can self-clean during rain or snow.

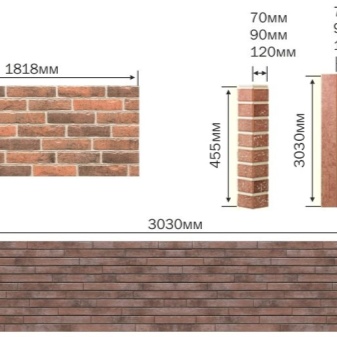

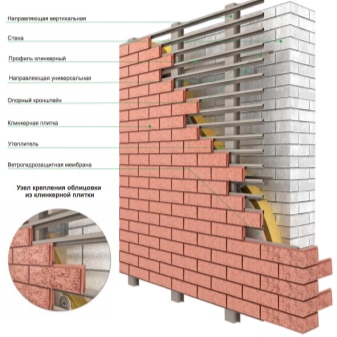

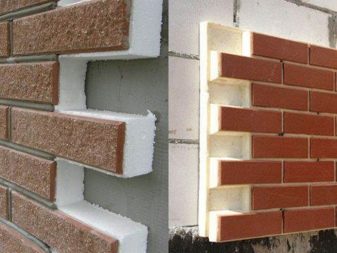

Clinker panels are used for facades and are considered one of the best for finishing the base. Such a coating consists of tiles that perfectly retain heat and withstand temperature fluctuations, and a polyurethane foam base. Previously, clinker tiles were used exclusively for sidewalks and paths, but once its exceptional properties were discovered, another application appeared.

Installation of clinker panels is unusual: first, a matrix is formed into which the tiles are laid and filled with liquid insulation. Clinker panels are attached by using self-tapping screws both to the facade itself and to the lathing. This material is very durable, environmentally friendly, but also expensive.

The tiles are made from clay, which is then painted to the desired shade. The panels do not lose their sight in the sun, do not crack or crumble. Also, the facade will be protected from fungi and mold, as the material allows very little moisture to pass through.

Clinker panels are also called thermal panels. They maintain the best temperature at any time of the year and allow you to significantly save on heating your home.

It should be noted that polyurethane foam acts as a component contributing to insulation - a fire-resistant and temperature-regulating material. Polyurethane foam must be foamed and have a cellular structure. Marble chips are placed in each cell at a high temperature.

Installation is also possible at any time of the year. Among the disadvantages of polyurethane tiles are the rather high price and instability of ceramics. In addition, polyurethane foam is vapor-tight, therefore, during installation, it is necessary to maintain a gap between the tile and the wall itself so that condensation does not form. It should be added that it is clinker tiles with polyurethane foam that can create "ceramic" panels, decorated with tiles.

Metal

Metal facade panels are made of aluminum or steel, galvanized or stainless steel. More recently, panels made of copper or zinc have been used for cladding facades. Usually the surface of the coating is smooth, but it is also possible to make it volumetric - perforated or decorated with additional ribs. The thickness of the steel is approximately 0.5 millimeters. The metal plates themselves are most often coated with a polymer coating - like a brick or natural stone, polyester, plastisol or pural.

The weight of steel panels is about 9 kilograms per square meter, while aluminum panels are 7 kilograms. In general, metal plates can serve their owners for up to 30 years, both at temperatures of -50 and +50 degrees. They are waterproof, resistant to mechanical stress and chemicals and absolutely fireproof. Like other boards, they are distinguished by the presence of a wide range of shades and textures.

The main disadvantage is the fact that the metal does not retain heat well, therefore additional thermal insulation will be required. In addition, there will be a need for additional elements, as a result of which money spending will increase. Speaking of metal, it is worth mentioning that it accumulates static electricity, which is also a disadvantage. Aluminum is deprived of this, but it costs much more. Steel panels are stronger, but aluminum panels are better adapted to temperature fluctuations.

Polymer-protected metal panels have many advantages: here and long years of operation, and resistance to temperature extremes, and sound insulation, and protection from moisture. They are durable and sturdy, sold in various colors and designs, therefore they are widely used in construction. Among the disadvantages, only low thermal conductivity and the need for additional elements can be indicated.

Polymers

The main polymer used to create facade panels is polyvinyl chloride, or PVC. There are two types of them: basement siding and facade siding. The first has the shape of a rectangle, imitates a stone or brick and has a size of approximately 120 centimeters by 50 centimeters. The second consists of long thin plates, called lamellas, with an average size of 340 by 22 centimeters. Both variations are easily completed with additional elements, with the help of which corners, cornices and other "inconvenient" places are decorated.

PVC panels are quite cheap, therefore they are used everywhere. The most popular variety is considered to be vinyl siding, which has a textured wood-like surface or smooth.

Installation of vinyl panels is carried out from the bottom up. At the bottom, each panel has a lock, and at the top there is an edge for fixing to the base and another lock. Thus, the panels are connected to each other with two locks, but the joints are invisible to the eye.

Vinyl siding has been in operation for about 30 years at any temperature. Unlike metal plates, it retains heat inside the house, but is less resistant and capable of cracking at very low temperatures. Strong gusts of wind will also annoy the owners - the panels will begin to vibrate and deform. But high fire resistance will avoid fire problems.

There are also polymer panels reinforced with fiberglass and polymer concrete. They are very persistent, resistant, not amenable to any impact. Unfortunately, when the panels melt, they begin to release toxic substances, which is very dangerous. The installation of micromarble coverings is the same as the installation of vinyl.

Speaking of polymer, it is definitely worth mentioning polymer sand panels for brick. They are made from stone talc and polymers using UV stabilizers. Such a coating is extremely easy to install - there is no need for a wooden frame, no mortars, or glue. The panels are simply laid on a plastered or concrete wall and fixed to it with a locking system.

Such a facade is environmentally friendly, reliable and very lightweight. There are various design and color options, which again gives you the opportunity to experiment with style. The panels can have a layer of polystyrene foam insulation, which only increases the number of advantages of this coating.

"Brick" facade panels are relatively expensive, but the result is worth the cost. They cope with various temperature conditions, high humidity and look very attractive.

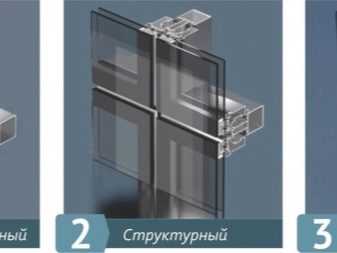

Glass Panels

Glass panels for the arrangement of facades are chosen by the owners of status mansions with an original design. The glass chosen for such a coating undergoes additional processing: it is laminated or tempered. The result is a coating that can even be bulletproof. In addition, the material is often endowed with special effects. Panels can be matte, mirrored or opaque. Thus, glass panels allow you to bring a variety of design ideas to life.

Of course, the advantages of such panels include their original appearance, thermal insulation, noise protection and high cost. The material does not produce harmful waves, does not have an unpleasant odor and other toxic fumes, and is absolutely environmentally friendly for the environment and humans. In addition, thanks to the transparency of the glass, as well as various decorative finishes, the owner of the building can receive any level of light input that he wants at one time or another. Fastening systems also allow you to create structures of non-standard shapes and of any complexity.

Among the disadvantages are the high cost and complexity of installation. Of course, it is also inconvenient that they need to be washed regularly.

Glass facades are post-transom, structural, hinged and translucent spider. The first option is the most common. Such panels are mounted on special strips called crossbars. They can be horizontal or vertical.

Also in the construction of the lathing there are racks. Often, the outer part is decorated with different decor.

Structural glazing creates a visually consistent coating, since all fastening elements are hidden behind the panels.The materials are fixed with a sealing adhesive that is resistant to temperature fluctuations and high humidity. Despite its fragile appearance, the design is absolutely safe, reliable and durable.

Resistant metal profiles are placed at the base of the curtain walls. The space between the building wall and the covering serves as a ventilation layer. Usually, this type is chosen for glazing loggias and balconies, decoration of shopping centers and office buildings.

Finally, spider glass façade panels are delivered without frames, so no hinges are needed. The parts themselves are fastened to each other with elastic clips, and to the wall the covering is attached to steel brackets.

A natural stone

Connoisseurs of stone have a choice: to decorate the building with natural or artificial materials.

- In the first case, they will receive an exceptionally durable and decent-looking coating that will protect the house from all possible "adversity": low temperatures, and ultraviolet radiation, and mechanical damage and even alkalis. The few disadvantages include the significant weight of the structure, poor sound insulation and high thermal conductivity.

- In the second case, the owners will be able to save on the cost of the material itself, without losing its visual appeal, and, moreover, significantly insulate the walls. Artificial stone, for example, made of polystyrene concrete, is easy to install and has approximately similar properties.

Panels of this type consist of two layers: the first is insulation, the second is decorative. A coating with imitation "like a stone" is mounted either on a pre-designed metal frame, as, for example, by the company "Dolomit", or on a special glue.

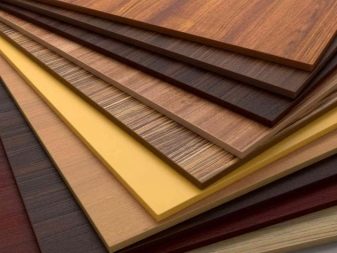

Wood fibers

Wood fiber that has been previously hot pressed can be found in wood facade panels. The organic polymer released in this process "binds" the particles. The surface of such a coating is treated with a protective solution, which increases its service life.

Wood fiber panels look like real wood, but have much better technological characteristics. They are durable and resistant, safe for human health and the environment, do not deform and protect against noise.

The disadvantages, however, include high flammability and "swelling" up to 20% of moisture, which, in principle, can be eliminated by using special means. For example, it can be a paraffin-based emulsion. The service life is about 15 years.

The slabs are attached to the frame with self-tapping screws due to the presence of a perforated edge. The covering elements are connected to each other as a ridge and a groove.

Views

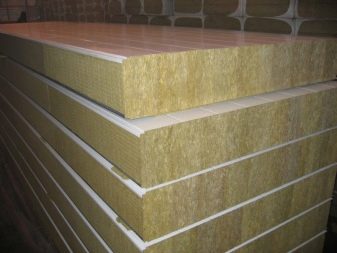

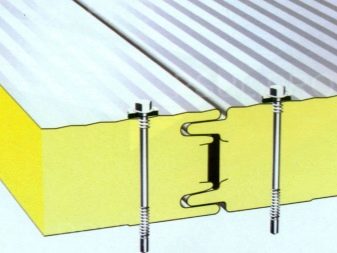

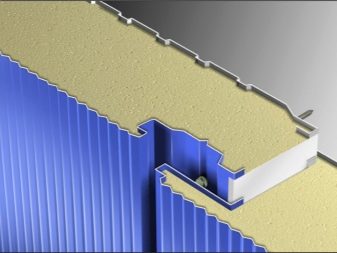

For cladding outside, they are very often used sandwich facade panels... Such a coating consists of two metal sheets of 0.5 mm each, between which a heater and a vapor barrier are placed.

Such multi-layer "sandwiches" are usually made from alloys of aluminum and galvanized steel with magnesium and manganese. Although they are thin, they are quite durable, which is a big plus for the exterior. The only drawback of wall panels is the fact that they exhibit low thermal insulation properties.

They function for up to 30 years, are ecological, fireproof and resistant to moisture. The panels are mounted on self-tapping screws, and they are joined together in the “tongue-and-groove” format.

Externally, sandwiches can imitate plaster, stone and other natural materials. They serve for more than 30 years, do not corrode or rot. Cassette "sandwiches" are chosen for areas with cold climates and frequent temperature changes. Their structure is as follows: a heater is placed inside a thin steel structure, and the facade panel itself is on top. Three-layer "sandwiches" based on moisture-resistant plywood have the following structure: ceramic tiles on the outside and polyurethane foam as thermal insulation.

In terms of format, facade panels are rectangular, in the form of a medium-sized module or in the form of an elongated rather narrow strip. They can be sold in a variety of shades, smooth or perforated. The colors for facade panels are determined according to the RAL catalog, for example, terracotta, orange, blue, lilac and even red. The panels are also divided depending on the availability of insulation according to the type of fastening (with locks and not connecting to each other) and the material of manufacture.

It is also very important to be able to understand what siding is. Some experts believe that facade panels and siding are two different things. Their main difference is that the siding has one layer, and the front panels have several. That is why panels, unlike siding, are able to be responsible for sound insulation and thermal insulation.

Others hold the view that siding is a type of facade panels. It consists of separate panels, similar to boards, which are fastened together with a lock and a perforated edge for nails. The stripes can be from 2 to 6 meters long, 10 millimeters thick and 10-30 centimeters wide.

There is aluminum siding - absolutely resistant to moisture penetration, not corroded, but quite expensive. Then vinyl siding is isolated - strips made of PVC. They also produce wood, cement and metal siding. Plinth siding is a type of vinyl panel used specifically for plinth trim. Such a coating has higher strength characteristics, because the basement is exposed to destructive factors much more than the rest of the house. Most often, basement siding models imitate alternative natural facing materials: wood, stone, brick, and others.

Selection Tips

Getting started with the choice of facade panels, you first need to familiarize yourself with their manufacturers and price ranges. The most famous are Holzplast, Alfa-Profil, Royal, Alsama and Novik. In addition to them, models from other manufacturers from the USA, Germany, Canada and Russia are presented on the market. As for the cost, you can find the price of both 400 rubles per piece (in the case of PVC), and 2000 per square meter. The price for natural stone panels will depend on the preferred material.

In addition, it is important to consider the following points.

- Feature of the structure. For private residential buildings, panels are recommended, one of the components of which is concrete, in warm colors. For public buildings, cold shades and polymer models are most often chosen.

- The area where the house is located is important. If it is a cold climate for most of the year, then it is better to install panels equipped with insulation.

- Technological characteristics are important - strength, flammability, sound insulation and others. It is worth considering the cost as well. There are panels on sale in various price categories, so inspired by the low price, it is imperative to find out everything about the manufacturer and read the reviews. Finally, the selected façade panels should be compatible with the landscape, other buildings and the overall style of decoration.

- To select facade panels for plastering, which will not be distinguished from high-quality processing, but with this installation will take place in the shortest possible time, you should pay attention to the coating of fiber panels. Fiber cement boards have marble chips as decorative aggregates and look very dignified. The panel can be textured or smooth surface.

- Facade clinker panels made of foamed polyurethane foam reduce the cost of heating the house by about 60%, so they are worth purchasing for those who want to reduce fixed costs. Clinker thermal panels are made similar to ordinary brick, wood or stone.They can have a rough or smooth structure, chipped or ribbed surface.

- So that the clinker plates fit perfectly into the uniform design of the site, it is necessary that they be combined with the sidewalk, and with the fence, and with the garage, and with other elements. If the house has already been insulated earlier, then you can do without insulation and save on thermal insulation. Installation of such panels is carried out on a base that is filled with mineral wool.

- Facade aquapanel is considered a relatively new material, which is used for both external and internal decoration of buildings. The inner layer of such a coating is made of cement with mineral additives. The outer surfaces and longitudinal edges are reinforced with fiberglass mesh, which gives them strength. Thanks to the reinforcing fiberglass mesh, the plate can be bent dry without preliminary moistening, with a radius of curvature of 1 meter, which allows the material to be used to create curved surfaces. Such material is able to perfectly resist moisture, therefore aquapanels are used in places where such exposure should be avoided. Usually the material is used as a base for plaster and ceramic tiles.

- Vinyl siding can be installed on any type of substrate - concrete surface, brick wall, wooden lathing. Facing with natural stone cannot demonstrate such versatility, therefore, if you want to create an aristocratic look, you should give preference to artificial stone.

- Making out the lower part of the house, which is adjacent to the foundation, it is important to choose the most moisture-resistant lining. Therefore, PVC panels are usually bought for these purposes. They are able to save the building from freezing, prevent the walls from getting wet and the formation of ugly white streaks on them.

The lower part of the house, adjacent to the foundation, is always difficult to cover. The proximity to groundwater and the blind area leads to the fact that the cladding should be as resistant to moisture as possible. Otherwise, the owners will have to make repairs every year. The use of PVC basement siding will help to avoid such problems.

- Porcelain stoneware in its properties and characteristics is similar to natural stone, therefore it is used both in low-rise construction and in high-rise buildings. The cladding made of porcelain stoneware favorably emphasizes the status. Porcelain stoneware has excellent characteristics: it does not wear out, cracks and stains do not appear on it. The original appearance can persist for decades.

- The most popular panels for facing residential buildings are thermal panels for brick or natural stone. They look as dignified as real materials, but respond better to various influences. For example, a real brick can change its color under the influence of the weather, but the artificial cladding will remain intact. If a more budgetary option is needed, then you should pay attention to cement-based panels. They also have an outer decorative layer that allows you to decorate your home with dignity.

- Sandwich panels do not require additional work, therefore they are chosen in a situation of a limited time period.

- The variety of facade panels allows you to choose the cladding to your liking, quality and price and create a unique look for your home. Combining products, and experimenting with shapes and shades are welcome. In order not to make a mistake, you should pay attention to the certificates of conformity, warranty coupons and detailed instructions. Ideally, panels, accessories and accessories should be produced by the same company.

Stages of work

- As a rule, at the stage of preparation for installation with your own hands it is necessary to process the wall for fastening the facade panels... First, all the protrusions are removed, then the old cladding is cleaned, and then the wall is treated with an agent that prevents the formation of fungus. If the walls are uneven, then the panels will be mounted on a frame, wood or metal.

- The base should be checked for evenness using a building level. If the differences turn out to be more than 1 centimeter, then fastening the panels to the glue will be impossible. In this case, alignment is carried out. In addition, the walls must be primed, both brick and concrete, and wooden ones are treated with an antiseptic.

- The installation of the lathing takes place in advance. The frame is constructed in a vertical or horizontal arrangement of all the constituent elements. The lathing should not follow the unevenness of the wall surface. A gap for ventilation must be left between the cladding material and the wall. The cavity formed between the surface of the building and the panels is filled with insulation materials, foam or mineral wool. Before proceeding to the installation of the lathing, it is necessary to lay a rather thick and durable cellophane film.

- It is important to correctly determine the level of the first row of cladding.using the starter bar. Wall panels are usually fixed from ground level at a height of 30 centimeters. It is advisable to start the cladding from the corners. After the first row is ready, all the gaps between the wall and the material are filled with polyurethane foam. If in the process it turns out that the panel does not fit in a row, it is cut with a grinder.

- Fiber cement panels are mounted on self-tapping screws. Metal plates are attached to the lathing after the facade of private houses has been insulated. Plastic panels are mounted on the frame using fasteners. Clinker, as well as fiber cement, are attached to self-tapping screws.

- Generally, assembly is done either with a special glue, or the panels are mounted on a prepared frame made of wood or metal. When using glue, the cladding is laid directly on the surface of the walls. It is important to understand that this technology is only suitable for perfectly flat surfaces. This type of installation is used for clinker panels, which perform the function of additional insulation and decorative finishing. The bottom row of panels is always installed according to the starting strip. If the installation is carried out with glue, then the work must be done in dry weather. Weather conditions are irrelevant for installation on battens. It should be added that a layer of insulation is sometimes laid under the facing plates. This is especially recommended if the facade panels have a homogeneous structure.

- When installing metal panels, the crate consists of guides, which are located vertically, and the panels themselves will be mounted horizontally. In the case of vertical installation, the tightness of the joints will be broken. In the process, self-tapping screws or nails are used that do not corrode. When installing metal panels, it should be borne in mind that additional elements will be required that cost additional money.

- Wood fiber facade panels fastened by the following system: there is a perforation at the edge of the panels, through this perforation there is already a fastener for self-tapping screws.

- Vinyl panels are connected to each other thanks to latches, one of which is located on the edge. Thus, sections of different sizes are assembled, which are then attached with self-tapping screws to the wall of the building. The panels are fixed with locks and in parallel cover the perforated fastener from the eye. Installation is carried out with an overlap from the ground, horizontally. Holes for self-tapping screws are cut with a certain gap, which will come in handy in case of swelling or compression of materials during temperature fluctuations. Nails are selected from aluminum or from other anti-corrosion material.

- Polyurethane panels are interconnected as a "tongue" and "groove", but are mounted vertically. The facade coating is attached to the frame with stainless steel screws, which will be invisible upon completion of the work.

- The sandwich panels are attached to the frame with self-tapping screws in the case of wooden and metal battens, and on concrete walls with dowels. The panels are also connected to each other according to the “tongue-and-groove” system. This scheme is chosen to prevent moisture from entering the walls of the house and to create high-quality adhesion of parts to each other.

- The installation of the porcelain stoneware facade is carried out with glue. It should be composed of two components, one of which is polyurethane. The tiles are glued to a cellular fiberglass surface, which will prevent fragments from shedding in case of damage.

At the very end of the installation process, grouting is carried out, if necessary. This will give the coating a complete aesthetic appearance.

Beautiful examples

- Stylish glass panels allow you to create futuristic homes with an abundance of light in the rooms. They go well with white or steel panels made from other materials.

- Bright light green siding will make the exterior of your home unforgettable. Panels of calm shades of wood shavings are suitable for it.

- For a classic style, it is worth choosing polymer panels in white, beige, coffee or cream colors. In this case, the roof is made in dark shades.

- The combination of panels of different colors and textures always allows you to create a unique look of the building. At the same time, it is recommended to use no more than three shades for wall decoration, one of which will be the main one, and the other two will be additional.

- The combination of yellow and gray plastic panels will look very impressive and modern.

- A structure completely decorated with metal panels can look overly gloomy. Therefore, it is worth diluting it with some light panels and, of course, not skimping on window openings.

- A combination of wooden and decorative panels for brickwork or artificial stone will look beautiful and noble.

- A small country house can be decorated in a Swiss style: make a roof of natural wood and place light panels on the facade.

- If there are many trees on the site, then green, yellow and brown will look good on the facade. If the area is deserted, then preference should be given to red and orange surfaces with a relief structure.

- Terraces and other annexes should be decorated in the same style as the main house. For example, for a building located on the shore of a reservoir, the most appropriate colors will be blue, blue and aqua.

For information on how to sheathe the facade of a house with panels, see the video below.

The comment was sent successfully.