Ebbs for the base: the subtleties of selection and installation

There are many ways and designs that help protect a building from the negative effects of the environment, especially from contact with moisture. It is customary to protect the basement of any building with the help of installation of ebbs, which are available on the market in a wide variety.

Peculiarities

The design of the basement of the house, due to the fact that it is exposed to a significant load, is thicker than the foundation of the building. As a result, precipitation, including water and snow, can accumulate on its protrusions. Such neoplasms contribute to the wetting of the concrete surface, as a result, some of the constituent elements are washed out of the material. After some time, the result of such a contact during the period of temperature drops will be cracking of the base.

To reduce the risk of situations that result in a decrease in the operational life of the structure, experts recommend using special ebb tides to protect the basement of the foundation.

Products are presented on the market in a large assortment, and can be made from different raw materials.

A plinth flush is a metal or plastic sloped strip, the installation of which will help protect the base from moisture. It is fixed in the area where the building wall and the basement are connected.

The main function of ebb tides is to protect the foundation from precipitation that flows down from roofs, windows and upper floors.

Regardless of the type of material used for the construction of a building, it will require protection from the influence of moisture, which in each individual case has a destructive effect - leads to the formation of cracks, the development of fungus or mold, as well as the loss of the thermal insulation qualities of the material. And these defects, taken together or separately, lead to premature aging of the entire building and a reduction in its operational life.

In addition, in addition to protecting and creating an optimal microclimate, base / plinth eaves provide aesthetic appeal to the building., acting as an element that allows you to create an outwardly complete and laconic design.

Before installing the product, it is worthwhile to study the device for the basement flashing, to understand the presented range of these products, as well as in the installation features.

A competent and thorough approach to the selection of elements will help in the future to avoid additional costs associated with the dismantling of a worn out ebb and the purchase of a new protective product.

Views

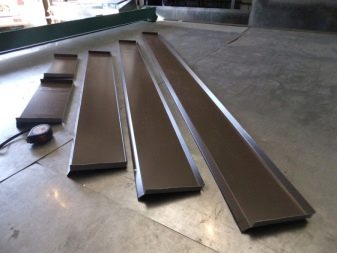

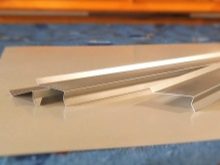

These products, regardless of the size and type of raw materials from which they are made, have the form of a bar that resembles a shelf. As a rule, ebbs can be with a width of 50 to 400 mm.

It is necessary to fix the basement flashing along the perimeter of the foundation on the protruding part of the surface, given that its location should be performed with a slight slope, about 5-10 degrees, directed in the direction opposite to the building.

This location technology will ensure the unhindered flow of water, but not along the base of the structure, but at some distance from it. In some cases, homeowners make their own products from water-repellent raw materials. On the shelves of building supermarkets, the ebb are presented from the following materials:

- plastic products;

- galvanized steel outflows and subspecies of such products, the surface of which is treated with a polymer coating or painted;

- copper strips;

- aluminum drips;

- clinker products.

Based on the type of raw materials used for the manufacture of ebbs, they are classified. In order not to be mistaken with the choice of products, you should carefully study the characteristics of each type of basement ebb.

It is recommended to install PVC products on the facades of buildings faced with vinyl siding. Such products in their texture are close to the basic finishing material, therefore they will more harmoniously fit into the overall exterior.

Thanks to a large selection of color solutions, you can choose a product that is as close as possible to the color of the siding. Polyvinyl chloride ebbs are made to order, so it will not be difficult to purchase an element that is suitable in size and shape.

PVC products are distinguished by a long service life, as well as resistance to environmental factors, including not only weather conditions, but also mechanical stress. These characteristics make the product very popular. In addition, polyvinyl chloride ebbs are notable for their low cost.

The disadvantages of the described goods include the fragility of the material and the non-repairability of the products.

Metal eaves have a different price range - there are steel strips, which can be attributed to goods of the middle price category, as well as products with a polymer coating, which are expensive.

At the request of the consumer, basement ebbs are produced with an exclusive appearance.

Metal products resemble a shelf with a fold at the edge. It is designed to secure products to the wall of the house. The second fold is bent down. The planks are usually about 2 meters long and 5-30 cm wide. The thickness of the steel sheet is usually about 1 mm. Ebb tides can be painted in any color or retain their standard appearance.

The main advantage of metal products is ease of installation, as well as resistance to mechanical stress. The most popular are aluminum castings, copper products are less popular due to the high price and a number of specific features associated with care.

Fastening of such ebbs to the base is carried out using self-tapping screws or dowels. The main thing is to take into account that the planks must be overlapped one on top of the other.

Concrete products should be purchased for buildings whose cladding is made of natural or artificial stone or brick. For the production of such basement castings, cement M450 is used, which has high resistance to negative temperatures. For shaping the product, silicone containers are used, which can have a wide variety of configurations.

Ebb tides of standard sizes are represented by products with a length of 3.9 m to 6 m, the width is selected taking into account the dimensions of the base. The color range of concrete products is quite diverse, the installed planks can be painted in any desired color. However, the installation of products must be foreseen in advance during the construction of the building, since the ebb tides are heavy. Fixation of the basement castings made of concrete is carried out using mortar.

Buildings finished with clinker tiles require ebbs made from the same raw materials. Similar products are available and sold in the same supermarket building departments as the cladding material.

Products require special professionalism during installation, in addition, their presence is foreseen in advance during the work on the project of future construction.

Mounting

Before proceeding with the installation of the ebb for the basement, it is worthwhile to carry out a number of preparatory work. First of all, you need to determine the depth and width of the base, as well as make sure the integrity of the wall.

Even minor defects must be repaired with sealant, plaster or putty.After carrying out these restoration work and complete drying of the composition, you can proceed to the installation of the ebb.

The installation of the ebbs is carried out on the mortar, brackets or other elements intended for fixation, and only after the finishing lining of the basement. Before installation, the horizontal line of the foundation is checked using a level.

To complete the work, you will need the following tools:

- scissors for metal work;

- hammer;

- screwdriver and pliers;

- puncher and screwdriver;

- fasteners.

Correct installation of ebb tides, regardless of the purpose of the building, be it a change house or a residential building, will help protect the basement from moisture penetration.

In order for the products to be attached to the base as reliably as possible, slopes must be made. They are performed according to the following scheme:

- a radius lace is attached to the corner, which is pulled to another corner and leveled;

- they dilute the cement composition with which the slope is performed, while it is necessary to ensure that the slope angle of the slope is at least 15 degrees.

Subsequent work must be postponed for several days to allow the applied solution to finally harden.

Fastenings of ebb tides can be carried out directly to the wall of the house or to special guides, to which the external cladding will be fixed.

To increase the ability of products to drain water from the foundation, they are fixed with a protrusion of about 5 centimeters. To the guides, installation is carried out with self-tapping screws, to the walls - using dowels.

The joints of the elements with each other must be coated with frost-resistant sealant. The minimum overlap of the planks should be about 3 centimeters. The inner and outer corners are cut with a tool from the remnants of the planks.

Wide basement sills need to be attached to brackets, other mounting methods will not be able to firmly fix the products, and they will move from the wind.

Advice

- The cost of products is formed taking into account several nuances. First of all, the type of raw material from which the ebb is produced is taken into account. It is not worth focusing only on the price of the product, since expensive protective strips will recoup their cost in a short time, and products that are notable for a low price can also effectively perform their functional tasks.

- Based on practical experience, we can confidently say that a competently and professionally performed installation of ebb tides will make it possible to significantly save on foundation repairs.

- When deciding to purchase a particular type of ebb tide, it is necessary to be based primarily on the advantages of the material. Aluminum drip tides are frost-resistant, and also perfectly tolerate high levels of humidity. Copper products are resistant to mechanical wear. Galvanized steel strips are popular due to their visual appeal and practicality. In the assortment of basement ebbs, concrete products are notable for a high level of reliability of the structure being created, since concrete itself can easily cope with heavy loads. But having an undeniable advantage, concrete ebbs will require the involvement of specialized workers for the installation of products.

- The choice of product color depends on the individual preferences of the homeowners, as well as on the overall style of the building's cladding. Wooden structures have always attracted with their appearance, however, metal products can also decorate and emphasize the overall style of home decoration. To avoid disappointment, it will be useful to perform several options for sketches in order to visually see the result of the installation.

For information on how to correctly make the ebb angle of the base, see the next video.

The comment was sent successfully.