Modern curtain wall systems

The facade of a building, regardless of its type and version, is obliged to protect and decorate the building. Depending on the type of building, materials used and installation methods, several varieties are distinguished. Ventilated curtain facades are becoming more widespread.

Device

Facade systems are designed to protect the building structure from negative environmental factors, thereby extending their service life. Modern facades have a varied and attractive appearance. At a relatively affordable cost, they are able to accurately imitate the expensive exterior decoration made of stone and wood.

Depending on the method, there are 2 types of facade systems:

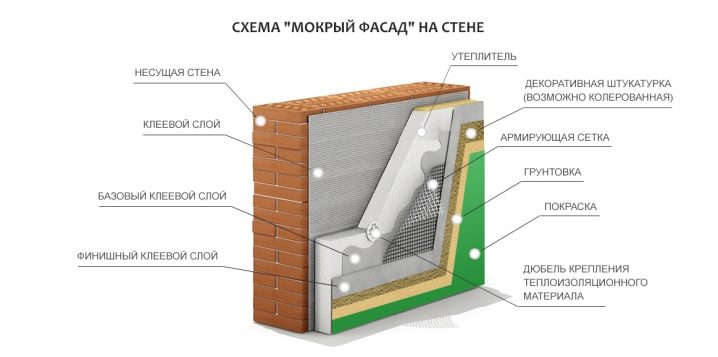

- Wet. The wet façade is made using building mixes. The most common option is to decorate external walls with decorative plaster.

- Hinged. This option involves the use of slabs and panels that are attached to anchors, bolts and other fasteners. For such structures, a subsystem is required - a frame or lathing, which is built along the entire surface of the walls.

Depending on whether an air gap is left between the wall and the facade material, there are 2 types of facades:

- ventilated;

- unventilated (solid).

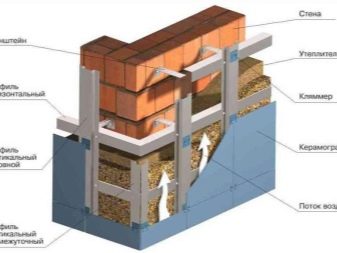

Ventilated facades are organized by installing a frame that is attached to the wall of the building. The frame is sheathed with finishing materials. There is space between the frame and the wall for free air circulation.

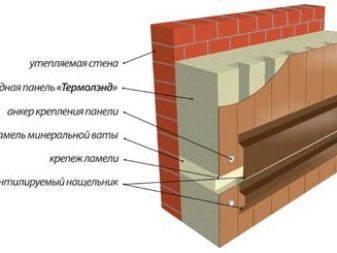

If necessary, a heater is laid between the frame and the wall, in which case the air remains between the frame and the heat-insulating material.

You can often hear such a classification of facade systems as their division into wet and ventilated. However, this approach is incorrect, since the classification is based on different criteria. Among the wet facades there are ventilated ones. Likewise, curtain systems can be solid (for example, glass facades).

Advantages and disadvantages

Suspended systems allow you to abandon the decorative finishing of the walls, which significantly reduces the size of the estimate for construction or repair. In addition, the use of lathing allows you to hide irregularities and other surface defects.

It is important that such facades are versatile. They can be mounted on walls made of building blocks and bricks, wood, on the walls of prefabricated frame structures.

Suspended facades can be installed both on a newly built building and on an existing building that needs repair or reconstruction.

Materials for the hinged system can be mounted even at subzero temperatures, which makes it possible to talk about the possibility of year-round installation. An important point - PVC-based facades tend to expand and contract when temperatures change, which must be taken into account during operation. For example, vinyl siding panels, when installed in the cold season, before installation, should be kept for at least a day in room conditions.

Most of the curtain walls today are multi-layer "pies", one of the elements of which is insulation. Moreover, models of finishing panels appeared on sale, on which a layer of insulation was applied by hot pressing.

The use of heat-insulating panels greatly simplifies and speeds up installation, eliminates the need to look for a suitable insulation for a specific type of facade panels.

The hinged system allows you to efficiently organize ventilated facades. Their advantage is due to the presence of air space between the walls and the crate. Its presence allows you to remove excess moisture and vapors from the room, preventing their penetration into the thickness of the insulation and facade material. Subject to the installation technologies, hinged systems are biostable - mold, fungi do not form on their surface, they are not covered with moss.

With proper installation and selection of material with high moisture resistance, it is possible to create frost-resistant facades. The frost resistance indicators of some models exceed 300 cycles. Such materials are optimal for northern regions.

Facades demonstrate low thermal conductivity and are distinguished by a long (up to 50 years) period of operation.

Such facade solutions make it possible to achieve high heat and sound insulation performance, reliably protect the surface of the walls, which determines their durability. By changing the angle of inclination or direction of the material for finishing, you can achieve originality in the design of the facade, create decorative architectural elements.

Among the disadvantages, some note the high cost of organizing a curtain wall system. On average, 1 m2 of construction costs 2,000 rubles (including materials for the lathing, insulation, hydro and vapor barrier materials, external panels). However, any installer will say that such a structure will pay off after 5-7 years of operation.

Air pockets increase the risk of fire spreading rapidly in the event of a fire. This can only be avoided by using non-flammable (or relatively safe from the point of view of fire hazard) materials, as well as by treating all combustible elements with fire retardants (for example, a wooden frame). It is fair to point out experts that the relative novelty of the system does not yet allow to achieve its worthy fire protection.

It is also important to choose materials (finishing and thermal insulation) that do not emit toxic compounds during combustion.

Designs and varieties

The applied attachments are of the following types:

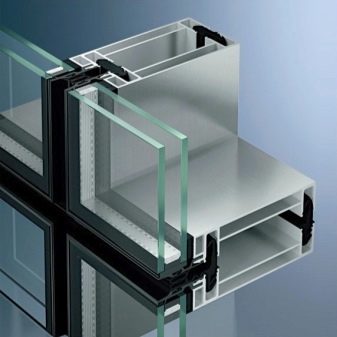

- Translucent. The basis of such panels is tempered high-strength glass or double-glazed windows.

- Opaque varieties are composite panels, stone slabs or frosted glass. Among the most popular finishing materials for curtain walls are porcelain stoneware, vinyl, metal and fiber cement siding and panels, thermal panels and profiled sheets, linear and cassette panels.

If we talk about the frame on which the facade materials are attached, then they are made from the following materials:

- Aluminum. The aluminum frame offers an optimal combination of strength and low weight. In addition, the material is not subject to corrosion, which significantly extends the service life of the facade system.

- Steel. The product can be a steel profile, a powder-coated galvanized steel frame or a stainless steel version.

- Wood. Today, wooden substructures are used infrequently, due to their higher cost, as well as their need to be treated with fire retardants and moisture-repellent compounds.

Depending on the type of assembly, skeleton subsystems can be as follows:

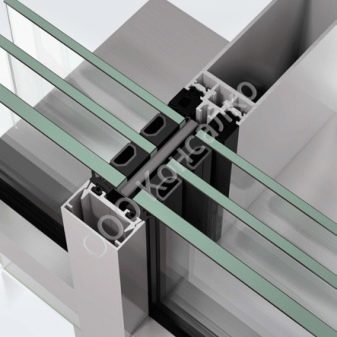

- Post-transom. This is the simplest structure, which is a frame along the entire facade of the building, consisting of thin (up to 5 cm wide) racks and crossbars. Such structures are usually used for translucent panels, since this technology allows you to achieve maximum transparency of the facade, airiness.The visually finished facade looks like a glass surface, divided at equal intervals by lines (vertical and horizontal).

- Modular... Such frames are manufactured at the factory and are metal profiles, the length of which is 2-4 m. They are sold in a collapsible form. After transportation to the construction site, the profiles are assembled into a frame.

The advantage of this method is efficiency and ease of assembly. In addition, some manufacturers produce a subsystem for certain types of curtain coatings. This ensures 100% compatibility between the frame and the finishing material. The user does not need to select and purchase fixing elements - they are also included in the kit.

Depending on the direction of the frame elements, it may look like this:

- vertical (usually mounted under a profiled sheet, porcelain stoneware, siding, facing cassettes);

- horizontal (also suitable for cladding with profiled sheets or when decorating walls with linear panels);

- cross (used for further facing with porcelain stoneware or cassettes).

The TechnoNIKOL trademark produces ventilated facades that are as safe as possible from the point of view of ignition and melting. Structurally, they consist of basalt granulate (front protective and decorative side), bitumen (provides antiseptic protection and moisture resistance of the system), fiberglass (acts as a reinforcement, accumulates infrared heat) and quartz sand (increases the strength of the slabs and their fire resistance, adjoins decorative layer).

The company produces not only facade, but also roof waterproofing materials. Its assortment includes ready-made modular systems that are distinguished by reliability, durability and a warranty period of up to several decades.

Manufacturers

The assortment of almost all companies that produce hinged facade systems includes several types of frames, various finishing materials and suitable fastening systems for them.

Regular inspections make it possible to establish that a sufficiently large number of manufacturers do not have a complete set of technical documentation for the products they sell. In this regard, the buyer should take a responsible approach to the choice of the facade system and carefully study the product documentation.

Leading positions are occupied by such companies as Metal-Profile (a Russian brand with production bases in Moscow), Kraspan (a company from Krasnoyarsk), Zias, NordFox, and the products of the domestic Ronson plant also enjoy the trust of buyers.

A large selection of subsystems is offered by the Premier company. Here you can find frames for lightweight, heavyweight and combined finishing materials. Since the manufacture of hinged systems is the leading activity of the plant, its products are distinguished by thoughtfulness and reliability.

The advantage of the brand is the affordability of the systems. Inexpensive aluminum structures can be found in the collections of the Sirius brand, products from galvanized steel with a powder coating - in the Fasst brand line.

Various types of subsystems (5 types) are produced by the firms "Vector-Fasad", "Kos-Corner" and "Alternative". Their assortment includes subsystems that can be mounted both on walls and in interfloor ceilings.

Those looking for energy efficient structures should pay attention to the Termolend two-layer panels. Their distinctive feature is a high rate of heat efficiency and the absence of through air pockets in the insulation layer due to the manufacturer's refusal to use brackets. Fastening is carried out on the anchor system.

If façade glazing is required, Schuco transom-post systems are usually chosen. Facing material is presented by tempered glass, stained glass structures, tinted glass and analogs with a pattern.Window structures in the system are sliding and swinging, while they often do not stand out against the general background of the facade.

Among European brands, Baumit and Capatect deserve attention, whose products boast an accurate design thickness of each layer of the system, high fire safety and the use of the latest innovative developments in production. The most widespread in the domestic market are thermal insulation boards of these brands.

Eurofox is also a leading European manufacturer of facade systems. As one of the structural divisions of the company for the production of fasteners Hilti, it also produces curtain walls.

The product line includes 4 types of systems that are designed for fixing porcelain stoneware, profiled sheets, fiber cement panels and panels for a wet facade (plaster). The advantage is the ability to choose a suitable solution for different types of buildings, but the manufacturer has not yet produced systems for natural stone.

Mounting

The installation of a curtain wall is carried out in several stages:

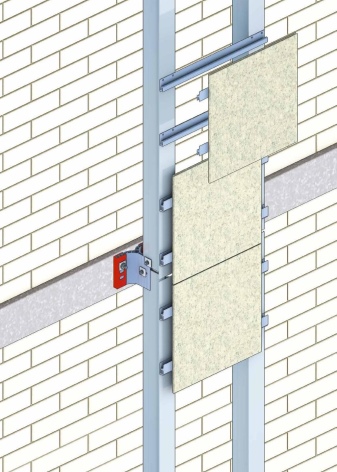

- The walls of the building are marked, along which the frame will be mounted in the future.

- Installation on brackets of a subsystem (homemade or factory-assembled). Before installing the bracket, be sure to make a hole for the anchor with a puncher.

For every 2 m kV, a certain number of fasteners is provided, which must necessarily have anti-corrosion properties. This is due to the fact that conditions favorable for the appearance of corrosion on the metal prevail in the ventilation gap.

As a result, the fasteners may rust and malfunction. In the worst case, it threatens the collapse of the facade. The substructure is fixed in one direction.

- Installation of insulation (it is unacceptable to use polystyrene plates in hinged structures). Installation of heat-insulating coating (basalt or mineral wool) is carried out from the bottom up.

- Installation of a windproof membrane to protect the insulation. The use of a moisture-proof film involves laying it with a slight overlap.

- Installation of finishing material is in progress. The technology depends on its type, for example, porcelain stoneware is fixed on a clamp, facade cassettes are hung on a carriage (special profile), and natural stone is fixed on a pre-installed horizontal bar. Different parts of the facade can have different textures; often the pediment of a building has the same stylistic solution as the walls.

It will not be superfluous to mention that the organization of a curtain facade implies the preparation of project documentation. All stages of installation, starting with the implementation of the markup, are carried out in strict accordance with the drawings.

Beautiful examples

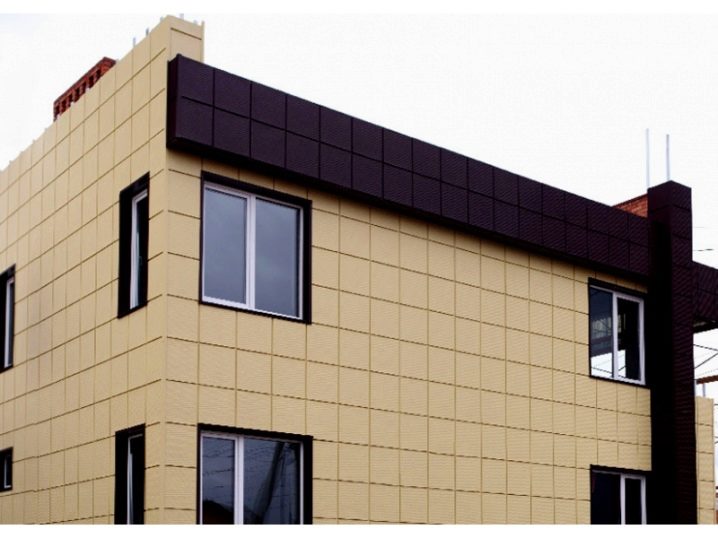

Curtain wall systems can look completely different depending on the panels used and their placement.

Porcelain stoneware slabs (artificial stone) are characterized by a respectable appearance, even visually, they are a reliable and durable material. As a rule, it is used to decorate large cottages and office buildings.

Cassette panels are no less popular for decorating public buildings, as well as factory buildings. Recently, there has been a tendency to use them in private construction. Due to the rather large dimensions of the cassettes, their installation does not take much time, the finished facade looks strict, laconic, but at the same time exquisite.

An important point is that porcelain stoneware slabs, cassette and linear (based on high-tech polyester) panels are fixed only on the factory metal frame.

The use of a block house imitating a log surface allows you to recreate the atmosphere of rustic comfort, special antiquity, a family estate.It can be either a wooden material (then a lathing made of wood and metal is used), as well as panels or siding for a block house on a metal lathing.

The ease of installation (due in part to the low weight of the material) is distinguished by vinyl siding, for which a wooden subsystem is also suitable. The facade material can have different shades (gentle or, on the contrary, bright), different orientation of the profiles, and also imitate natural surfaces.

See below for details of mounting a suspended ventilated facade.

The comment was sent successfully.