What are the bolts and how to choose them?

Having figured out what it is - a bolt, what bolts are, how they look, and how to choose them, it will be possible to work quite successfully with these hardware. There are various types of them: mounting BSR and eccentric bolt, elevator and shear bolts, ploughshare and other types. When choosing, you will have to take into account the marking, and it is also important to remember that the very handling of such fasteners is not too simple.

What it is?

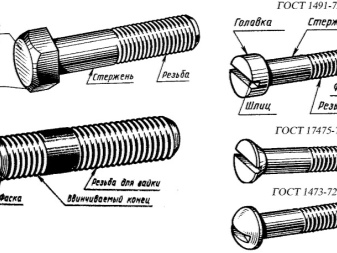

It is customary to call a bolt a fastener that resembles a rod with an external thread. Typically, such a product is equipped with a hex head designed for gripping with a key. A direct connection is not made by the fastener itself, but only in cooperation with a nut or other threaded product. In the past, when modern fasteners of this kind did not yet exist, any oblong cylindrical metal products could be called bolts.

However, today in this context this word is used only in special publications and when referring to various artifacts (the same "crossbow bolts"). Modern bolts are used very widely:

- in construction;

- in the household sphere;

- in industrial production;

- on transport;

- in electronics.

Views

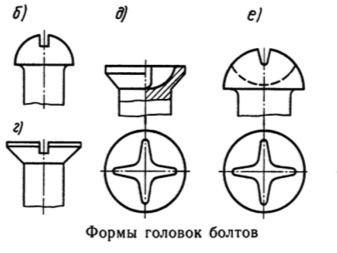

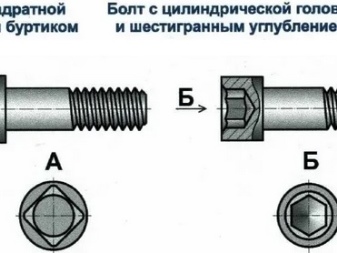

By the size and shape of the head

It is this part that is "responsible" for the transmission of the torque to the rest of the elements of the product. It forms a support surface. The hex head is more common than other types. You can work with it even with the most ordinary wrench. This is a universal product, but most often it is bought by machine-building and construction-repair organizations.

Models with a semicircular head are used in the manufacture of furniture. They also find application in the creation of fences. The countersunk head is relevant for radio devices and electrical equipment. It is perfectly flat and has internal slots, which makes it easy to tighten such a fastener with a screwdriver.

Products with a square head are used where it is especially important to prevent parts from shifting in relation to each other.

The working socket in this case has a corresponding geometric shape. In the furniture industry, as already mentioned, models with a round head are much more important. As for the dimensions, for most bolts the head reaches:

- 4;

- 5;

- 6;

- 8;

- 10;

- 12;

- 14 mm.

By the shape of the rod

This indicator depends on the technical requirements. Most often, rods are classified by length... In the case of a stepped bolt, the parts have different lengths. But predominantly there are structures in which the cross section is the same throughout the entire length.

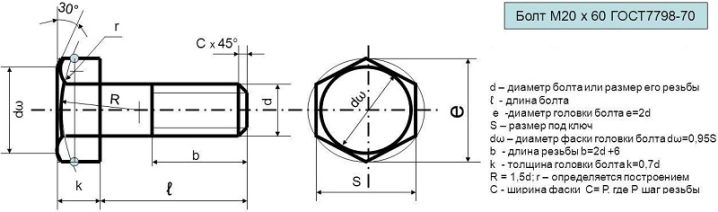

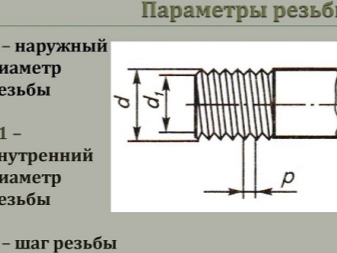

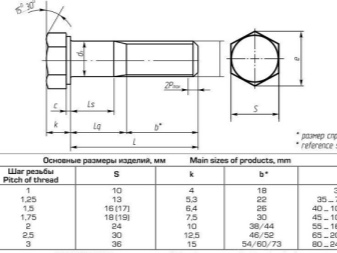

By type and pitch

The thread pitch is divided into:

- basic;

- small;

- especially small species.

As for the type of thread, it is divided into:

- metric;

- inch;

- trapezoidal;

- persistent format;

- round Edison carving.

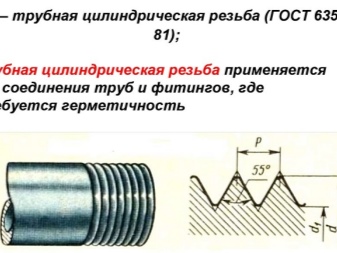

The metric version is more common than other types. Inch is typical for products made in the USA and England, as well as for water pipes. Specific pipe threads will be especially valuable where even a slight decrease in strength characteristics is unacceptable. Trapezoidal grooves are typical for screw-nut combinations.

As for the thrust type, it is justified primarily by the increased ability to transfer axial loads in one direction.

By version

It is a constructive approach defined by the standard... In the case of a hexagonal bolt, the design is considered to be the locking of the connection.A hole for a wire or a cotter pin is placed on the head or in another part. Sometimes in the first place is the reduction in the mass of the bolt while maintaining the dimensions and accuracy of installation. This is achieved by forming a depression in the head.

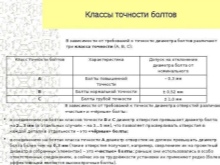

Accuracy class

The precision level expresses the degree of roughness of the grooves. A high category A is needed for precision instrumentation and other critical industries. The most frequently used category is B. The least accurate bolts are type C. They are used for unimportant connections.

By appointment

Elevator (other names - elevator or transport) bolt allows you to fix the buckets on the conveyor belt. In Russia, such products are manufactured according to individually prepared drawings. The DIN 15237 standard is used abroad. As a result, high productivity is ensured. The ploughshare bolt is significantly different. It includes a countersunk head. All such products meet the accuracy category C. The standards allow for slight deformations, including burrs or even slight defects in the thread. Basically, plow bolts (according to their name) are used to attach attachments to agricultural machines. The whisker is the part of the rod above the head.

The terminal bolt, contrary to the name, has nothing to do with radio engineering and electrical engineering. It is actively used in railway transport to ensure the highest possible speed of transport. The fastener has a prismatic head. The standard size is determined by the dimensions of the pads used. Basic norms are specified in GOST 10616. Molly bolt can be used for wood and drywall. It is also taken to work with other panels made of wood or wood-based.

The specificity of the hardware is associated with a special collet. Its outer side is complemented by a stubborn, spiked skirt. Thanks to such protrusions, scrolling is excluded.

As for decorative bolts, they look nice, but they are not applicable everywhere. So, a pleasant appearance does not at all justify their use in automobile wheels. There, such a product will be too unreliable. At the same time, it is worth emphasizing that bolts with increased decorativeness can justify themselves in the design of dwellings. As part of furniture and other household items, they look very good.

Speaking of the types of fasteners, it would be strange to ignore the construction bolts. With their help, they collect:

- stairs;

- bridges;

- assembly scaffolding;

- lifting mechanisms.

The mortgage type of bolts is subject to GOST 16017-79. This product allows you to attach metal pads and rails to rail supports made of reinforced concrete. Sometimes embedded fasteners provide a connection to the ground or metal structures. In many cases, grade 20 steel is used for their manufacture. Most often, the surface is coated with anti-corrosion compounds; the layer reaches 9-18 microns in thickness.

As for the butt models, they, again, are used on the railway. With their help, rails of various standard sizes are connected. Each of these products is complemented with a nut that meets the state standard. On domestic highways, such a connection is still more common than welded assemblies.

Particular attention should be paid to BSR, or otherwise, a self-supporting spacer bolt, which is distinguished by its special quality and reliability.

The fixing part is made in elastic band format. Most often, steel grades are used for its manufacture:

- 20;

- 35;

- 09G2S.

Caliber can vary significantly. It is allowed to knock on the BSR with a hammer, but only through a special doboinik. After immersion in the hole, knocking is unacceptable, only the expansion of the main element is allowed. For this purpose, you need to rotate the nut. Tightening is done with a torque wrench. In cars, the eccentric bolt is widely used. Such products are in demand primarily when fastening wheels.The shear bolt is mainly used on self-propelled vehicles. They are the ones that are vulnerable in machines. Indeed, it is precisely such units that "take the blow" that otherwise could have hit the engine and other sensitive, important parts of the mechanism.

Flanged bolts must comply with DIN 6921. Such a product evenly distributes the load. Twisted metric threads are applied to one part. The other edge has a head adapted to the wrench. The flange successfully replaces a plain washer. There is an option with a smooth clamping surface. With this design, the connection will be hermetically sealed. Even fluid leakage is almost completely excluded. But corrugated surfaces have their own plus. When using them, even a fairly intense vibration load will not lead to unscrewing of the connection.

Anti-vandal bolts are also widely used. They are used in places of mass stay of people. It is there that the danger that someone will try to steal or damage certain things is greatest. The solution to the problem is the use of complex and atypical spline configurations.

If you need to dismantle such hardware, use special keys and nozzles. In some cases, austenitic steel is used for the manufacture of products.

The T-bolt is popular. It is used in close connection with the corresponding nuts. The result is superior structural reliability. Installation is possible in any convenient place. The fixation will be very secure. Hand or power tools can be used to secure T-bolts.

This model is supported by:

- mechanical fortress;

- ease of use;

- pleasant prices;

- versatility of application;

- corrosion resistance.

Materials (edit)

For the manufacture of bolts, black carbon metal is often used. The softest products get based on St3 steel. If you need a particularly strong product, you will have to use 35ХГСА and 40ХНМА alloys. Stainless steels are used much less often, galvanized bolts are generally considered to be protected from corrosion. Along with them, there are also phosphated, oxidized, nickel-plated models.

When choosing steel, its strength class must be taken into account.... It should be borne in mind that the bolt and nut must be identical... Copper bolts, as well as washers and nuts, are commonly used for electrical work. There, such fasteners are needed to fix wires and cables. Brass fasteners are used where high resistance to corrosion and acids, combined with wear resistance and ductility, are in the first place.

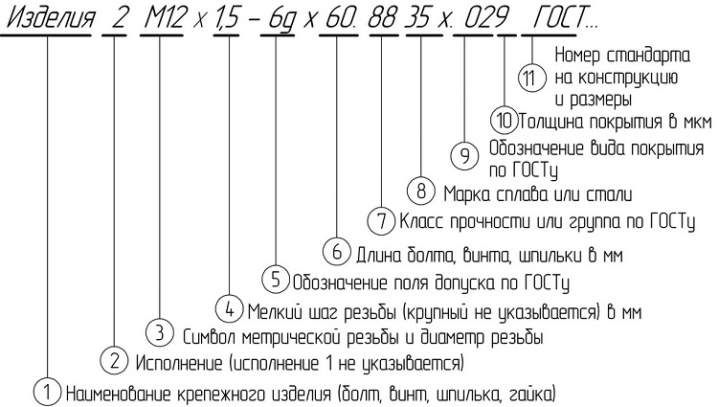

Marking

The designations applied to the bolts are mysterious only at first glance. In fact, they are very informative and well thought out. If you come across a relatively old fastener issued in accordance with GOST 1977, then its marking is as follows:

- the letter mark of the manufacturer;

- temporary resistance of the bolt (reduced by 10);

- climatic category;

- metal melt number.

According to modern GOST, the designations are built according to the following scheme:

- factory brand;

- strength category according to the 2006 standard;

- climatic category;

- heat number;

- S symbol (if it is an extra strong oversized head bolt).

Nuances of choice

To begin with, you need to choose not so much size as specialization. It is impractical to use machine-building bolts in ordinary construction (as well as vice versa). Additionally, you need to understand the shape of the products, with the execution of their heads. Pay attention to the material used. It must meet the operating conditions.

In particularly difficult situations, bolts with press washers help. They are the least susceptible to vibration. Of course, you need to buy hardware either in reputable stores, or directly from large manufacturers with a decent reputation. The strength class of the metal is also taken into account.

It is useful to get acquainted with the provisions of GOST (even if the hardware is bought for personal use).

Features of working with bolts

When assembling any somewhat responsible structure in production, in construction, you must make a calculation. But in the household sphere, fasteners are usually chosen and mounted "by eye", since the cost of an error is far from so high. A rough estimate can be made using online calculators. But in this case, it is important to consider how important each parameter is, and what it can mean. When working with batteries and other electrical products, it is very important to choose the correct terminal for the bolt.

Often this already requires familiarity with the technical documentation and its conventions. And also the terminals are divided into private types. So, quite often there is a variant of a tinned connection in an assembly with a wire. The distance between bolts in metal structures cannot be less than 2.5 of their diameters. That is why, for the simplicity of determining such a parameter, as well as for uniformity of the load in any metal structure, only fasteners of a uniform size can be used.

In the extreme rows, the distance cannot exceed 8 diameters. A gap of up to 16 diameters is allowed in the middle row. From the center of the bolt to the edge of the foundation or the base of a different structure (assembly) there cannot be less than 2 sections of hardware. More accurate indicators can only be selected by qualified engineers who have studied the features of a particular case. If the bolt cannot be turned in or out, you can simply try to turn in the opposite direction to the direction originally chosen.

In many cases, this is enough to cope with even the most "rebellious" hardware. In cars, hardware is usually screwed in a clockwise direction, and to remove them, the movement must be opposite. The problem often arises of how to unscrew a sour bolt if it cannot be unscrewed by conventional means. A common mistake is to use maximum strength. It leads to the fact that the hardware can break, and then the extraction of its remnants will be further complicated.

A paradoxical but effective method is to try to tighten the fastener a little and then loosen it.

There is nothing surprising in this: it is likely that there is still an unused thread in the direction of travel. In addition, cranking destroys the integrity of limescale and oxides. Able to lightly tap the bolt, which also helps to loosen its holding force. Sometimes the hardware is heated with a burner, but first you need to make sure that it is completely safe. In some cases, the bolts are also soaked with kerosene, WD-40, or plain clean water.

In some cases, it is also necessary to unscrew a broken bolt. One of the options for solving the problem is heating with a burner or a building hairdryer, followed by sharp cooling. The difference in thermal expansion of the materials will make it easier to remove the problem part. The bolt itself can be grasped with pliers or clamping pliers (the second option is easier). The most time consuming approach is drilling out the broken hardware, but often nothing else remains.

The comment was sent successfully.