Everything you need to know about furniture bolts

Furniture made of wood, glass or metal cannot be imagined without fastening hardware. In order for furniture products to be durable and beautiful, it is important to use a properly selected headset, which should be in harmony with the material of the product and its design idea. Even a simple furniture bolt plays an important role in the manufacture of furniture - without this element, it is quite problematic to perform a solid assembly of parts. Fasteners can be made from different types of metal and come in a wide variety.

general description

Until metal fasteners appeared, furniture parts were assembled using wooden dowels or corners. A modern furniture bolt is made according to GOST standards, in the furniture industry it has one of the main positions. A bolt for assembling cabinets or chairs differs from construction hardware, also called a bolt. Furniture-type hardware provides not only strong fasteners, but also does not spoil the aesthetic appearance of the finished product.

Among other furniture hardware, the bolt is the most common element. Its design consists of a working rod in the form of a long cylinder and a head.

The cylindrical shank has a metric thread that attaches the nut to the bolt shank. The most popular are the bolts, in which the head looks like a hemisphere.

The reliability of the hardware is explained by the fact that it is made of durable alloys. Most often, the bolts are galvanized to protect the mount from corrosion. Sometimes you can find furniture hardware made of aluminum alloy or polymer plastics. If we compare the strength of building bolts, then furniture hardware, of course, is inferior to them, since they do not need to hold excessively large weight loads. For this reason furniture hardware is cheaper than construction bolts.

Applications

The only and main purpose of hardware for furniture - connection of prefabricated elements... But hardware of smaller sizes is used to assemble decorative fittings for the purpose of fastening for the handle, and they also act as a tie for assembling and tightly connecting the body parts of furniture to each other.

Despite the fact that furniture screeds are inferior in metal strength to construction hardware, their constriction potential is quite high.

In some cases, builders also use the connecting properties of a bolt with a semicircular head, in cases where the connecting fasteners will not be under a large weight or breaking load.

In modern furniture production, hardware is used for the following products:

- for the manufacture of sofas, kitchen cabinets, wardrobes and cupboards, countertops, dining tables, dressers and armchairs, beds and other items;

- to carry out restoration work with strong deterioration of furniture fittings and fasteners;

- for the device of garden gazebos, awnings, as well as for the manufacture of wooden stairs located inside the house;

- in all other cases, when the assembly assumes a secure round head bolt - in the manufacture of signs, lightweight structures, in the manufacture of accessories, door locks, and so on.

When purchasing new furniture, few of us pay attention to what kind of bolts the fasteners are made with. But for those who are engaged in furniture production, it is very important to be able to understand what types of furniture fasteners exist, how to choose the right type and size.

Species overview

Depending on how the furniture structure will be used, there are also types of round head bolts. Furniture hardware is divided among themselves by design and size. In addition, the models may differ in color - it can be black or silver, yellowish or copper.

By design

In addition to bolts with a round head, furniture makers have other types of hardware in service, differing from each other in their design.

- Confirmation (Euro screw) - this hardware has the form of a working rod in the form of a long cylinder with a countersunk head located at one end. On the surface of the head there are slots designed for a Phillips screwdriver or a hexagon. The size of the working rod of a cylindrical structure depends on what the Euro screw will be used for. For example, to join a chipboard that is 16 mm thick by standards, a 16 mm long confirmation is required. Sometimes, longer hardware is used to connect two elements, the length of which can reach 50 or 60 mm.

The most common parameters of the Euro screw are 7x50 mm, and the configuration of their splines is most often demanded for an internal hexagon. You can wrap such a confirmation using a screwdriver or a screwdriver, into which a bit with six faces is inserted.

In addition to hexagonal splines, cruciform shapes are no less popular, but compared to hex counterparts, this hardware does not provide a tight fastening, and it loosens rather quickly.

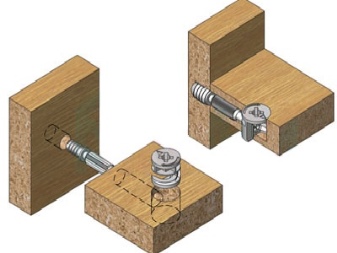

- Screw tie - The mount has 2 parts, which include a screw, an external thread and a nut in the form of a barrel. When twisting and tightening two furniture parts, one part is attracted to the end part of the second part. To perform fasteners, a through-type hole is drilled in one piece of furniture, and its diameter is slightly larger than a threaded screw. In the second workpiece, to which the first is adjacent, 2 holes are made. The first hole should be equal to the diameter of the first clamping piece and the second hole is drilled for the keg nut. Next, you need to make the exact connection of the holes with the hardware.

The Euro screw is used in the manufacture of furniture to create a rigid and strong fastening of parts to each other. Such a fastening would not have been possible if it were not for the metric thread on the working body of the Euro screw. The disadvantages of the confirmation are that it is rather difficult to perform fasteners using it, since this procedure requires great accuracy. In addition, the design of the fastener is visible on the furniture product, special decorative plugs help to hide it, but this cannot be done completely.

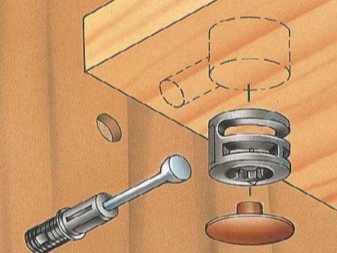

- Mini-fix coupler (conical) - to install it, there is no need to make a through hole in the furniture element. The type of fastening is similar to the previously described screw fastening. The difference lies in the fact that when fixing, the cylindrical rod is fixed in the pressed part of the workpiece by pulling it in with a tie. The tightening of the parts is due to the screw. Often, this type of screed is found in the places where the table top is fixed to the support base or on the front furniture elements of the frame type.

It is quite difficult to use a tapered coupler, therefore, a high degree of skill and experience is required to create such a fastener. An additional disadvantage is that the hardware has a small resource of repeated cycles of disassembly and assembly of a furniture product.

According to experts, in most cases, this fastener is disposable, and in a situation of re-installation, its complete replacement is required.

- Shelf holder - this fastener helps to securely hold the shelves in furniture cabinets, at the same time with this function the hardware creates rigidity for the entire frame of the product. The mount is made of 2 parts - the support mechanism for the shelf and the rod holding it. During installation, the hardware rod is screwed into the cabinet wall from the inside, and the supporting part of the structure is fixed on the shelf itself. The essence of the fastener lies in the fact that the rod enters the hook element of the eccentric device, as a result of which, by turning the screw, the shelf is pressed against the inner walls of the cabinet.

This type of hardware is also difficult to install and requires a highly skilled craftsman. In order to precisely dock the furniture elements, you will need not only to perform the correct markings, but also drill with milling. These manipulations are performed only with the use of special equipment.

- Intersectional coupler - it is used when it is necessary to interconnect the modules of cabinet furniture. The hardware design is a kind of bolt combined with a nut. The hollow structure of one part of the tie acts as a bolt in the form of a threaded sleeve. A threaded element is screwed into this sleeve, which acts as a tie. On the outer part of the sleeve there are round splines that prevent the hardware from spinning in the tie hole, therefore, it is the screwed part that must be rotated during installation, and not the sleeve itself.

This type of attachment is quite easy to use. This is a reliable hardware option for furniture assembly, it can be reused.

The screed forms a rigid form of fastening and is used to combine headsets from several items or cabinets for the kitchen, turning them into a single system, leveling minor differences in the height of suspended or floor structures.

- Screw with a semicircular or decorative head - the thread on the surface of a cylindrical rod is complete or can only occupy a part of it. Some bolt models are available with an equilateral square or whisker headrest. Such devices are necessary so that the nut does not unwind during rotation, thereby weakening the strength of the fastener. The bolt's rectangular headrest serves as a stop that contacts the surface of the furniture element and prevents the nut from rotating.

As for the semicircular head, such a smooth shape provides the consumer with a comfortable and safe use without the threat of injury from the projections of the hardware. This type of bolt is not only reliable and safe, but also does not spoil the overall appearance of the furniture. You can see similar hardware in almost every design of a bed, chair or sofa.

By form

Furniture hardware can differ from each other not only in design features, but also in appearance. For a certain type of assembly, different types of fasteners are used.

- Flange type - hardware with a flat round washer, which is located under a semicircular head.

- Classic type - has a cylindrical body with a metric thread at the end and a hexagonal head structure.

- Anchor type - consists of a rod with a full thread, a head of various structures and a metal tube with perforation in the form of cuts, which is put on the body of the rod. The head of the anchor can have slots that are suitable for hex or flat head screwdrivers. It is used when joining heavy furniture structures by weight.

- Folding type - instead of a hat, the hardware has only a rod with a round hole, which is adapted for a hexagon.

- Eye bolt - instead of a head, there is a loop at the end of the cylindrical rod, onto which the nuts are screwed.

The density of the fastening furniture joint depends on the type of screed and its shape.The choice of insufficiently strong hardware can lead to deformation of the finished furniture product or its destruction.

Strength classes

The steel grade from which the furniture hardware is made determines its strength class. In the furniture industry, fasteners are used whose strength ranges from 4.6 to 12.9. The decoding of these numbers is as follows:

5.6 is 5x100 = 500 N / mm2, while the material yield ratio is 60%.

The most in demand in the furniture industry are hardware, the class of which is from 4.6 to 6.6 and 6.8 including. If it is necessary to connect the heavy and most critical parts of the furniture structure, hardware is used whose strength is 8.8 - they are called high-strength. The higher the strength of the hardware, the more expensive its cost.

Materials (edit)

High-quality furniture hardware is not subject to corrosion, as it is either galvanized fasteners or made of the following materials:

- stainless steel - these are the most durable fasteners, the alloy of which includes nickel and carbon, and the finished hardware is subjected to additional galvanizing;

- copper - resistant to corrosion and temperature extremes, but have little strength under heavy load;

- brass - have resistance to corrosion, high performance properties and presentable appearance.

In some cases, hardware can be made of stainless steel A2 or A4. They are resistant to corrosion, acids and more durable than hardware and brass. These high strength fasteners are additionally zinc plated.

Dimensions (edit)

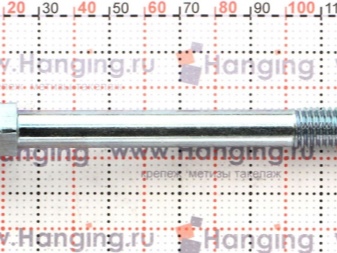

Modern manufacturers produce furniture hardware in a wide range of sizes. The bolt parameters are indicated using a cipher, for example, M8x30, M4 6x40 or M5 6x50 A4, where:

- M5 is a metric thread and its pitch on the hardware rod, there are markings M4, M6, M8, M10, M12;

- number 6 - diameter of the bolt pin, excluding the thread, in mm;

- number 50 is the length of the hardware, in mm;

- A4 - stainless steel grade.

The minimum length of furniture hardware is 40 mm, and the maximum can reach 120 and even 150 mm (in products with a square headrest). The diameter of the furniture bolt ranges from 5 to 7 mm.

Features of choice

When buying furniture fasteners, you need to pay attention to its appearance. Do not use bolts with an uneven thread, a bent head or a rod to assemble furniture. They also pay attention to the presence of rust, chips or cracks in the hardware - these defects will cause rapid wear of the fasteners.

When purchasing a bolt, you need to inspect the strength of its zinc coating.

If it is true, there will be no traces on your hands after turning the bolt, but if the product is painted with silver paint, thereby imitating galvanizing, the coloring composition will remain with you in the form of marks on your hands.

You can check the quality of the fasteners if you try to combine a bolt and a nut before buying - both hardware should be the same size and easily join.

The choice of high-quality hardware is best done in proven specialized retail chains that value their reputation, or entrust the buying process to an experienced person who can easily determine the quality product, the size and type of fasteners required to assemble a furniture product.

Installation tips

When buying cabinet furniture, a set of hardware for assembly is included in its package. If you are assembling furniture yourself, you will need to stock up on a certain type of tools:

- hex and Phillips screwdriver;

- screwdriver;

- electric drill and drill;

- wrench.

To assemble upholstered or cabinet furniture, you first need to make a marking of future holes - you need to approach this stage of work responsibly, since this moment is the key to a successful and accurate assembly. After completing the marking, you need to make holes according to the markings using a drill and a drill. Sometimes such holes are already made in the furniture industry.

Following the instructions, you need to fasten all the elements of the furniture product using the hardware supplied in the kit. In order for the fasteners to be reliable, you need to tighten the hardware all the way, but excessive efforts are unnecessary here - you can rip off the thread at the bolt. It is necessary to tighten the furniture bolts and ties using a hexagon or a screwdriver.

A screwdriver with bits is used at low speed.

Furniture connections are described in the next video.

The comment was sent successfully.