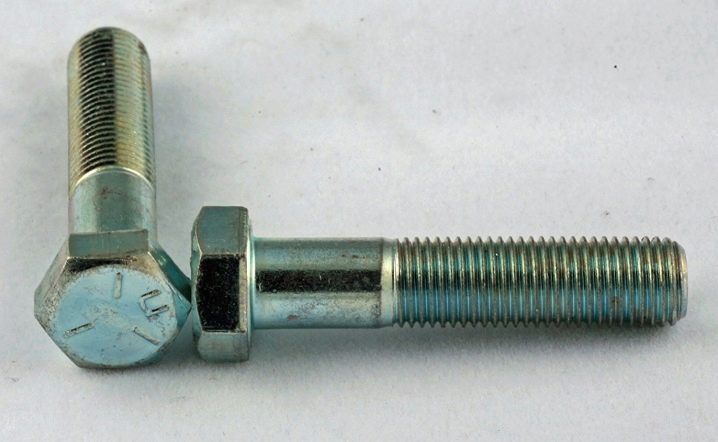

Bolt sizes

Bolt sizes are an extremely important topic for anyone interested in fasteners. First of all, the mass production of the M3-M4 and M5-M6, M7-M8 and M10-M12, M14-M16 and M18-M20 categories deserves attention. However, other bolt sizes will need to be examined as well.

Standard dimensions in millimeters

The M6 bolt got its name because it has a standard thread diameter of 6 mm. In this case, the length of the structural product can vary greatly. The M2 bolt is also quite widespread. He has a cross-section of the rod equal to 2 mm. The length of the structure is at least 16, maximum 20 mm; while the turnkey value is only 4.

In the case of the M3, a 12mm rod is formed. In M4, the nominal cross-section is predictably equal to a 4-mm segment. The following parameters are characteristic of the M5:

-

nominal value - 5 mm;

-

head length - 3;

-

turnkey dimension - 8.

M7 group hardware can vary in thread. It is in different cases 7-7.5 mm. For M8 fasteners, the length ranges from 8 to 100 mm. The diameter strictly corresponds to the brand designation. The same applies (with its meaning) to the M9 and M10 fasteners.

M12 bolts are produced with an increased level of accuracy. This is precisely the requirement set forth by the DIN standard. The cross-section of the core block for different specimens in each shipped batch differs by no more than 0.3 mm (a high-quality head is provided). The sub-key is 18mm (spec).

The groove pitch can be less or more - but the difference is only 1/2 millimeter.

For M14 hardware, the maximum permissible length is 300 mm. In this case, the head is raised by 8.8 mm. The same limiting length is typical for the M16. For these hardware, the key size is 24 mm. M17 is an extremely rare type, the parameters of which are determined not by the standard, but by order.

M18 fasteners in the past met the DIN 931 standards. However, today the release of such products is not allowed. With the corresponding nominal cross-section, the value for the tool is already 1.5 times larger. The length ranges from 40 to 140 mm. The M20 bolts are a rod - of course 20mm in length; they have a 12.5 mm head, and the length varies from 50 to 150 mm.

M24 fastening hardware is equipped with screw threads again. They have a length of at least 32 and no more than 200 mm. Tool size - 36 mm. The head unit is raised 15 mm. For M30 bolts - already traditionally - the rod size is shown by the number in the assigned brand, and the head reaches 17 mm in height.

In the case of the M36, the head can grow up to 22.5 mm. But this is not the only feature of such fasteners. The key size is 55 mm. Coarse (4mm) cutting pitch can be used. This completes the main "clean" indexes. But there is also:

-

М6х20 (hexagon 20mm);

-

М6х30 (the same, but the length is increased by 1.5 times);

-

M8x20, M8x25, M8x30 and M8x40 series - standard section 8 mm, length is indicated in the second part of the marking;

-

М10х30 and longer M10x40 - respectively, with a length of 30 and 40 mm;

-

bolts М12х50 - with a total diameter of 12 mm and a linear dimension of the rod of 50 mm;

- М16х70 - in this case, the cross-section is increased in comparison with the previous version by 4 mm, and the length - by 20 mm.

Inch bolt sizes

The dimensions of the bolts in this version are no less significant than the size of the hardware issued according to the metric system. Variety is also present here, because in the same way fasteners can solve different problems. We must remember about 3 different inch gradations - scales F, Lt, A. According to the F system, fasteners are distinguished:

-

5/32;

-

15/64;

-

5/16;

-

35/64.

For Lt hardware, the following values are assigned:

-

0,750;

-

1;

-

1,500;

-

2,250.

Grade A includes:

-

7/16;

-

9/16;

-

3/4;

-

2 1/4 (these are not all items, but only some for illustration purposes, more information can be obtained when ordering).

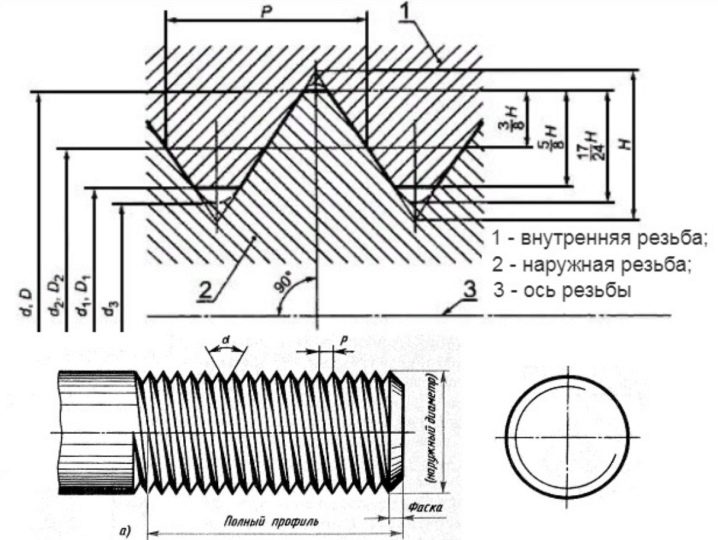

How to determine?

In theory, one could rely on the words of the sellers and the specifications of the manufacturers. But - only in some ideal world. In reality, it is important to check all this carefully, especially since it is sometimes necessary to find out what the size of the hardware is if it has lost its marking for some reason. The general designation in all metric product descriptions usually follows the DxPxL pattern.

These are, respectively, the diameter, the pitch of the grooves and the total length of the structure. It is in this order that independent measurements should be carried out. The section is determined in professional practice with a micrometer.

Less exactly the same result is given by a caliper. A rough estimate is made by tightly winding the wire (in multiples of 10 turns) and measuring with a ruler.

The same ruler can be used to determine the length. But it is more professional to have a caliper for such a purpose (especially because it will probably come in handy more than once). Sometimes the measurement gives a result that does not coincide with the table values. In this case, it is likely that the bolt is either defective or made to the inch standard. When using a countersunk head, its value is taken into account during measurements, and an open head can be ignored.

The comment was sent successfully.