Foil isolon: material for universal insulation

The construction market is replete with all new types of products, including foil-clad isolon - a universal material that has become widespread. Features of isolon, its types, scope of application - these and some other issues will be covered within the framework of this article.

Peculiarities

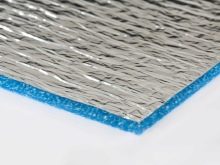

Foil-clad isolon is a heat-insulating material based on foamed polyethylene. Thermal performance is achieved by applying a metallized polypropylene film to the material. It can cover a layer of polyethylene on one or both sides.

Instead of a metallized film, foamed polyethylene can be covered with a layer of polished aluminum foil - this does not in any way affect the thermal insulation qualities of the product, but contributes to an increase in its strength.

High levels of thermal insulation are achieved through the use of a foil layer, which reflects 97% of thermal energy, while the material itself does not heat up. The structure of polyethylene assumes the presence of the smallest air bubbles, which provide low thermal conductivity. Foil isolon functions on the principle of a thermos: maintains the set temperature range inside the room, but does not heat up.

In addition, the material is characterized by high vapor permeability (0.031-0.04 mg / mhPa), which allows surfaces to breathe. Due to the ability of izolon to pass moisture vapor, it is possible to maintain optimal air humidity in the room, avoiding dampness of the walls, insulation, and finishing materials.

The moisture absorption of the insulation tends to zero, which guarantees the protection of surfaces from moisture penetration, as well as the formation of condensation inside the material.

In addition to high thermal efficiency, foil-clad isolon demonstrates good sound insulation (up to 32 dB and above).

Another plus is the lightness of the material, combined with increased strength properties. Low weight allows you to attach the insulation to any surface without requiring preliminary reinforcement.

It is important to remember that you cannot apply plaster or wallpaper over the isolon. These and other finishing materials, fixed directly on the insulation, will pull it back under their own weight.

Since the material is not designed for such loads, it will simply fall off. Finishing should be done only on a special crate.

Izolon is a rotting, environmentally friendly material that does not emit toxins during operation. Even when heated, it remains harmless. This significantly expands the scope of application of Isolon, which can be used not only for outdoor, but also for interior decoration of residential premises.

Along with environmental friendliness, it is worth highlighting the biostability of the product.: its surface is not susceptible to attack by microorganisms, the insulation is not covered with mold or fungus, does not become a home or food for rodents.

The metal film demonstrates chemical inertness, resistance to mechanical damage and weathering.

The material has a low thickness, therefore it is the most suitable material when it comes to internal thermal insulation. For materials of this type, not only technical indicators are important, but also the ability to save as large a usable area as possible after insulation - foil insulation is among the few insulating materials that copes with this task.

The disadvantage of the product is sometimes called a higher cost compared to other popular insulation materials. However, the difference in price is offset by the ease of laying the material (you can save on the purchase of steam and waterproofing materials, professional services), as well as the high thermal efficiency of foil insulation.

The calculations carried out prove that after its installation, it is possible to reduce the cost of heating the room by 30%. It is important that the service life of the material is at least 100 years.

Views

Heat-reflecting isolon is of 2 types: PPE and IPE... The first is a sewn insulation with closed cells, the second is an unstitched gas-filled analogue. There is no big difference in terms of thermal insulation capabilities between the materials.

If sound insulation indicators are important, then preference should be given to PPE, the sound insulation of which reaches 67%, while the same indicator for IPE is only 13%.

NPE is suitable for organizing refrigeration equipment and other structures exposed to low temperatures. The operating temperature is -80 ... +80 C, while the use of PES is possible at a temperature of -50 ... + 85C.

PPE is denser and thicker (thickness from 1 to 50 mm), moisture resistant material. NPE is thinner and more flexible (1-16 mm), but slightly inferior in terms of moisture absorption.

Material release form - washed and rolls. The thickness of the material varies from 3.5 to 20 mm. The length of the rolls ranges from 10 to 30 m with a width of 0.6–1.2 m. Depending on the length and width of the roll, it can hold from 6 to 36 m2 of material. Standard sizes of mats are 1x1 m, 1x2 m and 2x1.4 m.

Today on the market you can find several modifications of foil insulation.

- Izolon A. It is a heater, the thickness of which is 3-10 mm. Has a foil layer on one side.

- Izolon B. This type of material is protected by foil on both sides, which provides the best protection against mechanical damage.

- Izolon S. The most popular modification of the insulation, since one of the sides is sticky. In other words, it is a self-adhesive material, extremely convenient and easy to use.

- Isolon ALP. It is also a kind of self-adhesive insulation, the metallized layer of which is additionally protected with a plastic wrap up to 5 mm thick.

Scope of application

- Unique technical characteristics have become the reason for using isolon not only in construction, but also in the manufacture of industrial and refrigeration equipment.

- It is widely used in the petroleum and medical fields of activity, and is also suitable for solving plumbing tasks.

- The production of vests, sports equipment, packaging materials is also not complete without foil isolon.

- In medicine, it finds application in the production and packaging of special equipment, in the manufacture of orthopedic footwear.

- The mechanical engineering industry uses the material for automotive thermal insulation as well as soundproofing of automotive interiors.

- Thus, the material is suitable for industrial and domestic use. It is noteworthy that its installation does not require professional skills and special tools. If necessary, the material is easily cut with a knife. And the affordable price makes it possible for people with different financial capabilities to purchase it.

- The economy of consumption also becomes the reason for the widespread use of isolon on foil in everyday life. The user can cut the material as conveniently and economically as possible, and use small pieces of materials for thermal insulation of small areas, joints and gaps.

If we talk about the construction industry, then this thermal insulation material is optimal for finishing balconies, roofs, external and internal walls of the roof. It is suitable for any surfaces, including for thermal insulation of a wooden house, as it provides vapor permeability of the walls, which prevents wood from rotting.

- When finishing concrete walls, as well as surfaces made of building blocks, the insulation allows not only to reduce heat loss, but also to ensure the sound insulation of the room.

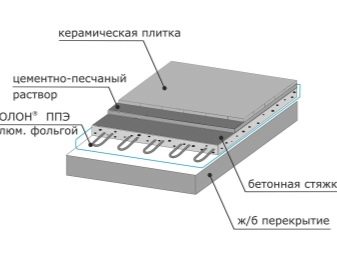

- Folgoizolon is used as a floor insulation: it can be placed under a warm floor system, used in a dry screed or as a substrate for floor coverings.

- The use of material for thermal insulation of the ceiling will be successful. Possessing excellent waterproof and vapor barrier properties, the material does not require additional waterproof and vapor barrier layers.

- Foil isolon is distinguished by its elasticity, the ability to take a given shape, therefore it is also suitable for insulating chimneys, pipelines, structures of complex configuration and non-standard shapes.

Installation technology

The surface of foil insulation is easy to damage, therefore, during transportation and installation, it needs careful handling. Depending on which part of the building or structure is subject to insulation, the technology for laying the material is selected.

- If the house is supposed to be insulated from the inside, then the isolon is placed between the wall and the finishing material, keeping an air space between them to increase thermal efficiency.

- The best option for attaching insulation will be the use of wooden battens that form a small crate on the wall. Foil insulation is fixed to it with the help of small nails. It is better to use a material that has a layer of foil on both sides (modification B). The joints are glued with aluminum tape in order to prevent "cold bridges".

- For thermal insulation of concrete floors, izolon is combined with another type of insulation. The latter is laid directly on concrete, between the floor joists. Foil insulation is laid on top of this structure, and a floor covering is laid on it. Typically, this type of insulation is used as a substrate for a laminate. In addition to heat saving, it helps to reduce the load on the main floor, and has a soundproofing effect.

- When insulating a balcony, it is better to resort to the installation of a multi-layer structure. The first layer in it is a one-sided foil isolon, laid out with a reflective layer. The next layer is insulation that can withstand increased mechanical stress, for example, polystyrene. Isolon is again laid on top of it. The laying technology repeats the principle of installation of the first isolon layer. After the insulation is completed, they proceed to the construction of the lathing on which the finishing materials are attached.

- The simplest way to insulate a living room in an apartment building, without resorting to dismantling the walls, is to place an isolon layer behind the heating radiators. The material will reflect heat from the batteries, directing it into the room.

- For insulation of floors, it is optimal to use the material of the ALP modification. Type C material is used mainly for insulating buildings for technical and domestic purposes. For heat and noise insulation of car interiors, isolon type C is usually used, combining it with special mastics.

Advice

When purchasing foil-insolon, consider its purpose - the thickness of the selected product depends on it. So, to insulate the floor, products with a thickness of 0.2-0.4 cm are sufficient. Interfloor floors are insulated using rolls or layers, the thickness of which is 1-3 cm. For thermal insulation, a 0.5-1 cm layer is sufficient. If izolon is used only as a sound-insulating layer, you can get by with a product 0.4-1 cm thick.

Despite the fact that laying the material is quite simple, it is important to follow the recommendations of specialists.

- Contact between foil-clad isolon and electrical wiring is inadmissible, since the metallized layer is an electrical conductor.

- When insulating a balcony, remember that foil insulation, like any other heat insulator, is designed to retain heat, and not generate it.In other words, when arranging a warm loggia, it is important to take care not only of insulation, but also of the presence of heat sources (underfloor heating system, heaters, etc.).

- Preventing the collection of condensate allows the preservation of an air gap between the insulation and other elements of the building structure.

- The material is always laid end-to-end. The joints are covered with aluminum tape.

For information on how to use foil isolon, see the following video:

The comment was sent successfully.