Izolon: what is it?

For construction and repair work, a certain list of materials is required, this also applies to processes related to the insulation of surfaces or bases. Izolon belongs to a product line that performs a similar functional task.

Peculiarities

The demand for such raw materials is explained by the need to insulate all buildings, regardless of the material that was used to erect the building.

Of course, for any homeowner, the issue of simplifying this task and saving money for work will always be relevant. This issue can be easily resolved by choosing practical and quality products. Among the variety on the market, such a product as isolon stands out. This is a material, the use of which will allow not only to insulate the working base, but also to form a high level of sound insulation. What is relevant for city houses located near noisy highways.

In addition, the justification for the use of insulation to preserve heat is confirmed by proven facts indicating that the loss of heat in rooms, which occurs through the walls of the building, is 65% of the total value.

The market for construction products is regularly replenished with materials that perform a thermal insulation function.

Improved technical characteristics are inherent in the new generation products, and isolon can be attributed to them.

The main feature of the material is its wide range of applications - it is used mainly in construction, but also purchased for use in the automotive industry and other areas of production.

In the first case, the following types of work can be distinguished for which an isolon is purchased:

- insulation and sound insulation of roofs, walls, floors, interfloor ceilings;

- steam insulation of baths and saunas.

Automotive production requires material in the following areas:

- insulation of the body from the inside to minimize vibration and noise, thermal insulation;

- ensuring the protection of metal against corrosion.

In addition to the above areas of material exploitation, it is in demand in the medical industry, in the production of refrigeration equipment, sewing workwear, in the packaging industry, and so on.

Sometimes such products are used in conjunction with their counterparts. But in comparison with most of the materials, isolon favorably stands out from the general list for its positive features.

- Russian products differ in their lower cost, in contrast to foreign materials, as well as from expensive cork. In addition, the material in question has practically the same properties as the cork.

- In comparison with glass wool, isolon is many times easier to install, in addition, it does not cause allergic reactions.

- Polyfoam is inferior in quality, since it is chemically active, which means it is not recommended for installation in residential premises.

Properties

Izolon is a synthetic raw material, the manufacturing process of which takes place by foaming polyethylene, therefore it consists of small closed cells. There are sheet types of material supplemented with a foil backing. Isolon is realized in the form of separate sheets, mats, tapes, blocks or rolls.

The following product specifications are highlighted:

- the heat reflection parameter is 97%;

- the material is allowed for use in the temperature range from +80 to -80 С;

- product thickness varies from 2 mm to 100 mm;

- water absorption rate does not exceed 1%;

- isolon density is 19-200 kg / m3;

- noise absorption up to 68%.

Certain material properties may differ depending on the type of product.

Izolon has a number of advantages:

- long service life, which is about 90 years;

- a good level of dynamic strength, due to which the material is resistant to mechanical stress;

- raw materials are neutral to chemicals, including oil, fuel oil and so on;

- high resistance to sunlight and atmospheric precipitation of any type, due to which the material is recommended for outdoor heat and sound insulation works;

- minimum weight - this feature allows you to exclude additional load on the bases during the laying of products;

- fire safety - raw materials do not burn, as a result of contact with fire, the material decomposes into water and carbon dioxide;

- due to the use of products, the level of sound insulation increases;

- good elasticity of isolon makes it possible to use it for bases and structures of any shape;

- the use of raw materials provides thermal insulation, based on consumer reviews, the level of savings on heating, provided that isolon is used, is about 30%;

- due to elasticity after mechanical action on the material, it returns to its original shape as soon as possible, such a characteristic allows the raw material to be reused;

- the minimum level of moisture absorption;

- the material does not rot;

- installation of thermal insulation is carried out quite quickly - products with a self-adhesive base are attached with an adhesive, the rest of the varieties are better glued to silicone glue or self-tapping screws or staples;

- the material is environmentally friendly, therefore it does not pose a danger to humans.

Izolon, like any other material, has disadvantages. These include the following nuances:

- foil-clad material should not be laid near electrical wiring, since aluminum is a current conductor;

- during the implementation of the insulation with the material, it is necessary to leave ventilation holes, since their absence can cause the accumulation of condensation;

- Isolon cannot be pasted over with wallpaper, or plaster should be applied.

Views

The manufacturing technology of the material includes three main stages, based on which the product is divided into types:

- mixing of ingredients, among which there is granular polyethylene, foaming agent and other components;

- extrusion;

- foaming due to which the foaming agent begins to "work", which provides a specific structure to the material - as a result, it looks like a porous sheet.

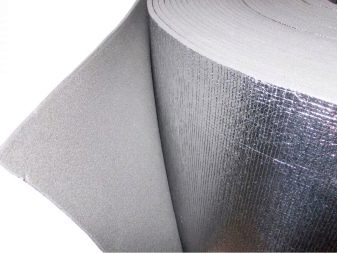

Foil products require another process - during lamination, aluminum foil is fixed to the polyethylene.

Considering the production method, two types of material can be distinguished.

Sewn - PPE

During production, changes occur in the components at the molecular level. This group includes products with a cross-ligamentous and reticular molecular basis. The specificity of the composition increases the resistance of the material to aggressive environments, in addition, the moisture resistance increases.

Unstitched - IPE

This type is characterized by the almost complete absence of bonds between the molecules of the components. In fact, these are gas-filled raw materials with a closed cell structure. Even at the stage of foaming during the heat treatment of the substance, carbon dioxide is added to it. It fills in pores that are larger than other materials. In addition, IPE has less flexibility.

Based on the method of stitching, it is possible to distinguish materials with a chemical or physical version of the execution of this task.

However, depending on the type of stitching, there is no difference in quality characteristics and appearance between the materials.

Taking into account the structure, isolon can be foil-coated or uncoated.

Foil

In composition, it is similar to the standard form, the only difference is the presence of a film on one or two sides. The film can be made of aluminum or have a metallized composition. Products are distinguished by high performance, therefore, they are recommended for use inside and outside buildings. The choice of products is carried out from the scope of application, for example, if izolon is needed for flooring, they prefer to purchase products with a heat-reflecting film, positioning it so that the side with the film is up.

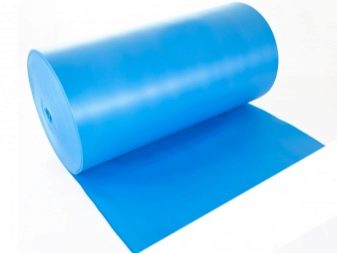

Uncoated products

The material does not contain additional layers, due to which its properties are slightly reduced. The cost of such products is much lower.

According to the fastening technology, some types of raw materials are distinguished.

Cover

You can glue the material to the base with an overlap, provided the thickness is the smallest, or butt-to-end, if you plan to use large sheets. For installation, construction tape is used, which is responsible for the tightness of the seams between the products.

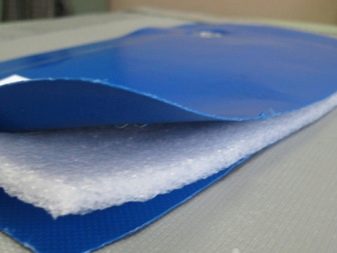

Self-adhesive material

Its installation is carried out to the fenced base, the fastening is carried out only after the protective film has been removed from the side that has an adhesive layer.

In addition to the main varieties, several more types of products can be distinguished, which are marked using a special abbreviation:

- isolone "A" - products with an aluminum layer on one side, its thickness can reach 10 mm;

- brand "B" - products with closed foil on both sides;

- "WITH" - a kind of thermal insulation, which has a self-adhesive base;

- ALP - self-adhesive raw materials with a white film on foil, the thickness of which is 3 mm.

Dimensions (edit)

In order to have a clear idea of what the material is, you should know what sizes the raw materials can be.

The thickness of the products directly depends on the field of application of the isolon. In order to additionally insulate the floor, you can opt for products with a thickness of up to 5 mm, the sound insulation of the roof should be done with sheets with a thickness of about 5-10 mm, interfloor ceilings require laying products with a thickness of 10-30 mm.

The size grid is very diverse: there are products with a thickness of up to 50 mm. The length of products can be from 2 to 300 m, products with a length of 500 meters are not produced. The width of the isolon varies from half a meter to 2 m. Products in the form of slabs have the following dimensions - 1x1.11 m or 2x1.4 m.

Installation technology

The main feature of the product is to ensure tightness, so all joints between the products should be glued. The working surface must be dry and free from various contaminants.

Experts say that one layer of 3-5 mm will be enough to provide high-quality insulation for the room. But the coldest places need to be insulated in several layers, or else acquire a material with a greater thickness and combine isolon with glass wool, forming an insulating sandwich.

Thermal insulation of the base of the floor includes the necessary list of works.

- After acquiring a material of appropriate thickness, surface preparation is carried out first. If there is an old coating on it, it is dismantled and the floor is leveled.

- If necessary, products of the required length and width are cut, for this you need to measure the working base. It is best to cut products with an ordinary knife.

- If self-adhesive material is used, then the protective film is removed before its installation, and then the raw materials are laid. In the course of work, the product must be slightly pressed against the surface in order to ensure a better fixation.

- Work with conventional products is carried out on acrylic adhesive compounds.

- Following the instructions for laying isolon on the base of the floor, before installing the raw materials, you need to put waterproofing. However, in most cases, flooring is not provided with additional moisture protection.

- A polyethylene film is laid on top of the thermal insulation, since the isolon does not absorb moisture.

- The material is fixed at the seams with tape, a construction stapler, or the products are welded to each other;

Tips & Tricks

When choosing an isolon, you should adhere to the following recommendations:

- The cost of thermal insulation products does not always determine its quality, therefore, attention should be paid to the manufacturer of the product, as well as its technical characteristics, in order to choose a product that is ideal for insulating a particular surface.

- Installation and fixing of seams cannot be performed with ordinary tape; for such purposes, there are specialized adhesive aluminum tapes.

- During the installation process, do not forget about the ventilation layer, which must be formed near the walls.

- Products, especially products with a foil layer, require compliance with the specified storage conditions, as well as accuracy during the transportation of goods.

- Violations made during the installation of the heat-insulating material are fraught with damage to the integrity and structure of the isolon, as a result - the products will lose their properties.

A very important parameter of izolon is the thickness of the products. It is this indicator that determines the scope of product exploitation.

Experts advise, during the acquisition of the material, to voice to the consultant or the seller of the goods the area in which the use of thermal insulation is planned.

In order to help make the right choice, manufacturers distinguish a product classification based on the thickness and scope of installation.

- In order to carry out work on the thermal insulation of pipes located directly underground, it is necessary to use PPE for work with a thickness of 15 to 45 mm with a foil layer.

- Sound insulation in multi-storey buildings between floors will have a high level of quality if you use an isolon 8-10 mm thick. Such material will be enough to reduce the noise from the movement of people living above, as well as to exclude the audibility of soft music from neighbors. But for buildings where the upper floor, for example, will be used as a sports hall, you need to purchase products with a greater thickness.

- Floor covering, for example, laminate, can be insulated with 3-5 mm products with high quality. For the "warm floor" system, you should give preference to products with a minimum thickness. Based on the type of floor screed, it is recommended to use different types of isolon: for a dry screed - foil-clad material, for a wet one - you need to lay products with a metallized layer.

- Thermal insulation of wood and concrete bases is carried out with products with a thickness of products up to 10 mm.

You will learn more about the material in the following video.

The comment was sent successfully.