Types of solid insulation for walls and their characteristics

During construction and finishing work, an important stage is the insulation of the walls of the room. Solid thermal insulation materials are distinguished by their reliability and long service life. They are easy to install, due to which this type of insulation has become widespread.

Advantages

The use of solid insulation has a number of advantages. First of all, they do not create problems during installation, which allows you to easily carry out work yourself. They are straight slabs that do not require lathing, frames and other additional structures to work with. And also these insulators do not need protective wood, plastic and metal panels, which, of course, saves a significant part of your money.

Their use allows you to achieve a flat surface, which is convenient for subsequent plastering and finishing.

Solid insulation boards have a strong structure, due to which they do not shrink or deform, and this plays an important role, given the vertical arrangement of materials.

In terms of the quality and performance of thermal insulation, they can be compared with ventilated facades, with the difference that the price of solid insulation is much lower. Besides, in comparison with soft insulation, they have a much longer service life.

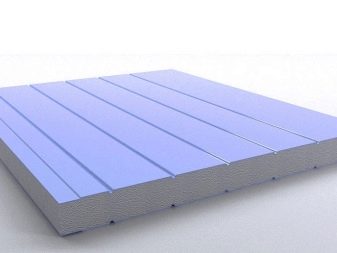

It should be borne in mind that some solid insulation, such as foam concrete, sandwich panels and others, can be used as independent structures in the construction of walls and partitions.

The dimensions of the material are fixed, this is very convenient when calculating the amount required for work. The available technical characteristics do not change over the course of the service life, which once again confirms the durability of these products.

Views

There are quite a few varieties of solid insulation. Each has a set of specific characteristics and properties. However, there are some types that are especially often used during construction and finishing work. Among solid insulation materials, one can note penoplex, stone wool, polymer concrete, foam glass and others. Let's consider the most popular varieties in more detail.

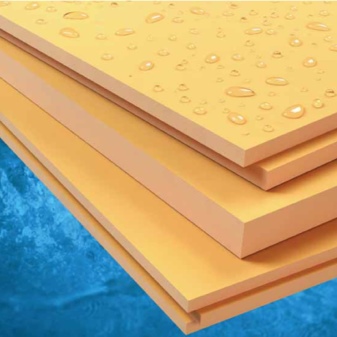

Extruded polystyrene foam

One of the most common types of insulation. The basis of the material is expanded polystyrene. It is also used in the manufacture of conventional expanded polystyrene and polystyrene foam. Extruded polystyrene foam is also called polystyrene foam. It can be used both for external and internal work.

This material perfectly tolerates temperatures from -50 to +75 degrees. However, it is recommended to avoid excessive heating, as it can deform the board.

At the same time, extruded polystyrene foam is able to retain heat in the room in winter, as well as protect the building from overheating in hot weather. The recommended temperature range is indicated on the label and may vary depending on the brand and density of the product.

Penoplex has a very low thermal conductivity, which does not decrease even when the material gets wet. Due to this, it is an excellent insulation not only for walls, but also for roofs, floors and foundations. It can be used to protect the surface from moisture, has a low vapor permeability.

This heat-insulating material does not react with a significant part of chemical compounds, however, when exposed to some, it can deform and even dissolve. These are, for example, gasoline, kerosene, oil-based paints, acetone, hydrocarbons and others.

Taking into account their strength, the plates are highly resistant to mechanical loads, when exposed to them, they retain their shape and size.

The material does not rot, does not decompose, is resistant to the occurrence of fungus and mold. However, rodents can cause serious harm to the insulation, as they are quite capable of gnawing it. In general, manufacturers declare the service life of the penoplex for more than 50 years without loss of characteristics and properties.

Extruded polystyrene foam does not create problems during installation. It is attached to a wall pre-treated with soil with special glue and dowels. The joints are filled with polyurethane foam. Further, the surface can be prepared for finishing. The work can be carried out both independently and with the help of specialists.

Consumers note the low weight of the material and its low price, which makes the boards a popular product on the market.

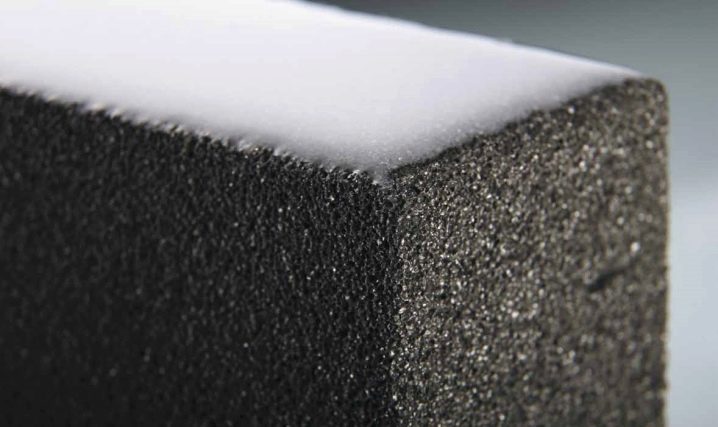

Stone wool

Stone wool for insulation is presented in the form of solid slabs and is widely used in construction. Basalt wool is used as a solid insulator. It can be used for both external and internal insulation work. It is quite easy to install, it is mounted on the walls without the use of additional structures. It has low thermal conductivity and is non-combustible.

Stone wool is resistant to fungi, mold and microorganisms, and is immune to rodents. It is an environmentally friendly and safe material with high insulation properties. The declared service life of the slabs without loss of basic properties is 50 years. It is mounted similarly to expanded polystyrene.

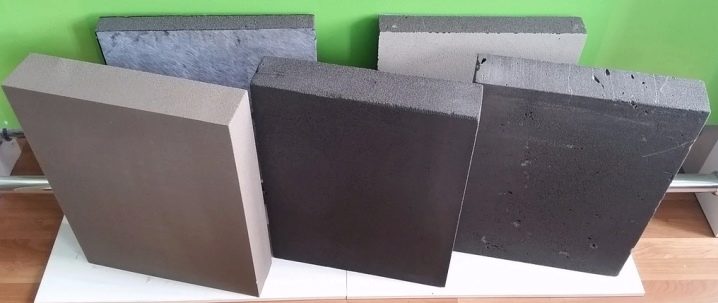

Foam glass

Foam glass is also a solid heat insulator. The production process is the foaming of molten glass, and the finished material resembles a honeycomb.

Foam glass is very tough and durable, it can withstand serious mechanical stress, and also has good thermal conductivity and sound insulation. It has excellent resistance to extreme temperature extremes, additional additives allow it to withstand indicators from -200 to +1000 degrees.

The material is highly resistant to moisture, bacteria, fungus and mold, while being environmentally friendly and non-toxic. The installation process has no peculiarities. The boards are glued and fixed with dowels. After that, the surface is plastered and the finish is applied. Manufacturers declare the lifespan of foam glass as unlimited.

Of the shortcomings, a rather large weight can be distinguished in comparison with other heat insulators.

For the features of solid insulation using stone wool as an example, see the video below.

The comment was sent successfully.