Technical characteristics and features of heaters for pipes Energoflex

Thermal insulation Energoflex is an ideal solution if it is necessary to insulate or, conversely, to protect communication systems such as pipelines and air ducts from overheating. The materials of these engineering structures also suffer from the negative effects of the environment, which leads to their destruction and malfunctions. A wide range of products and a variety of forms of release allows you to choose a high-quality insulation for pipes in each case.

Features of pipe insulation

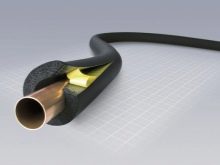

The Energoflex heat-insulating pipe is a heat-insulating material created by extrusion, at the next stage of production, high-pressure polyethylene is foamed using a butane-propane mixture, as a result of which an elastic pipe with a porous structure is obtained. Such air-filled micropores have high thermal insulation qualities:

- the product is resistant to a large temperature range - -40- + 95 degrees;

- has high flexibility and low weight;

- the material is impervious to mechanical stress and is virtually not susceptible to damage due to its high strength;

- thermal insulation is resistant to aggressive gases and liquids, therefore it is widely used for installation work in which lime, concrete or cement mortars are used;

- absolutely does not absorb water vapor;

- has moderate flammability (G2);

- simultaneously with insulation, it solves the problem of structure-borne noise;

- is an environmentally friendly material, so no protective clothing is required during installation.

It is impossible not to note the maximum elasticity and durability of tubular products., they can serve for a long time - up to 25 years, which is also noted in the certificate of compliance with established standards and quality standards.

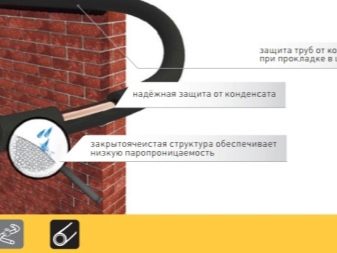

Not without drawbacks - the material is susceptible to ultraviolet rays, therefore, for communications outside, models with a protective coating made of a special polymer composition are provided.

Product advantages

The advantages of Energoflex thermal insulation can be considered its technical characteristics, which enable long-term and high-quality operation. In addition, it can be noted that with the help of such materials, it is possible to solve other important problems:

- icing of pipelines in winter;

- with an external heating system or overheating of ventilation - a lack of heat;

- susceptibility of metal parts of structures to corrosion in outdoor conditions.

Whichever product is chosen, its thermal insulation properties are not affected by the level of humidity, the materials are resistant not only to chemical, but also biological influences.

Installation of these products is extremely simple and convenient due to the presence of self-adhesive layers and special longitudinal cuts. When laying, it is not required to create an auxiliary layer to protect the thermal insulation from mechanical damage.

The pipe material has a length of 1 to 2 meters and a wall thickness of 6 to 20 mm. These products are packed in rolls with a total length of 10 to 30 m.

Since Energoflex products represent several types of products - tubes, sheets and rolls, each type should be considered in detail to judge the capabilities of each material.

Types of Energoflex Super models

The basic insulation is presented in the form of elastic hollow tubes with a cellular structure, with a wall thickness of 6 to 25 mm, a length of 1.2 or 2 m. The inner diameter of such cylinders is 15-42 mm.

The model with dimensions 42x9 mm and a length of 2 m is suitable not only for thermal insulation, but also for noise insulation of the internal pipeline and has the following advantages:

- safety of installation and use due to the fact that there are no chlorofluorocarbons in the composition;

- guaranteed absence of condensate causing corrosive processes;

- high level of noise absorption;

- economy in terms of electricity consumption;

- prevention of overheating and freezing of the media in cold and hot weather;

- good thermal conductivity;

- light weight for easy installation.

The scope of this material is quite wide, these are:

- hot and cold water supply;

- sewerage;

- heating;

- ventilation systems and air conditioning;

- main line pipeline.

Cylinders 2 meters long are characterized by increased moisture resistance and strength. Each product has a barcode with the standard size of the material. The color of the products is mostly gray.

A variation of this material is the two-meter tubes Super SK, on both sides of the longitudinal cut of which an adhesive base is applied, making installation easier and more reliable.

Under the Energoflex Super brand, products are produced in the form of sheets with a thickness of 10, 13 and 20 mm. These materials are most effective for vapor and moisture insulation when a multi-layer protection system is provided. Sheet products are more suitable for large pipe diameters.

Energoflex rolls are mainly used for insulating tanks and tanks, suitable for large pipe sizes. The standard width is 1-1.5 m, the thickness is from 10 to 25 mm, the length of the canvases is from 10 to 20 m. Application in ventilation systems requires the presence of materials marked "A", which means an additional reflective layer.

Product Description Super Protect

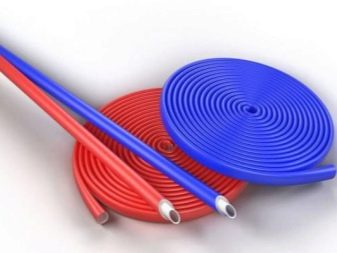

A special category of Super Protect products are heat-insulating pipes for piping structures of heating systems and plumbing, located inside the walls and floors of residential buildings.

Product characteristics:

- products are 10 m long;

- pipe diameters can be from 15 to 35 mm;

- wall thickness - from 4 to 9 mm;

- operation of thermal insulation is possible at a temperature range of -50- + 150 degrees.

The material is presented in two basic colors - red and blue, additional polymer protection significantly increases the strength of the insulation (by 50%), its compensating function is especially important during thermal expansion of pipes, hot water systems and heating. For convenience, the products are equipped with technical cuts. This insulation is designed for 25 years of operation.

Energoflex Black Star Products

Energoflex Black Star - a series of products for thermal insulation of ventilation and air conditioning systems. Polyethylene, processed using a special technology, is characterized by high resistance to moisture and steam penetration, therefore it serves as an excellent protection for the external parts of air conditioners located on the outside of the house.

Other tube properties:

- resistance to the influence of aggressive compositions of working solutions;

- immunity to mechanical deformation;

- safety due to the absence of harmful substances;

- long-term operation.

The inside of the pipes has a smooth surface, so the products can be easily installed on copper pipes without the use of talcum powder. The diameter of the products can vary from 6 to 28 mm, the thickness is standard (6-9 mm).

There are also other popular models in the product line.

Energoflex Black Star Split

Tubes 2 m long with additional protection for outdoor use. The manufacturer indicates that this material is well tolerated by ultraviolet radiation and has increased strength characteristics. At the same time, the thermal insulation of copper pipes does not require the use of casings and special sealing tapes. The total service life of the products is 16 years.

A particularly popular product for home and office air conditioning is considered to be the 18/6 Black Star type in the form of black cylinders.

Energoflex Black Star Duct

Insulation in the form of a roll cloth (length 5-30 m, width 1.2 m). The expanded foam film is ideal for large pipe diameters and has a self-adhesive layer that adheres optimally to metal surfaces. The product absorbs vibration and noise well. In the Duct Al model, the aluminum coating increases the thermal insulation layer.

Energoflex Acoustic

Special product for improving the acoustic performance of rooms. It is a tube with an internal serrated surface. The material, due to its high density, significantly reduces noise from both metal and plastic sewer pipes. The most demanded product size is 110x13 mm (diameter and thickness). Installation of a pipe product is extremely simple, can be carried out in a short time, and has a minimum amount of waste.

The manufacturer also took care of simplifying the installation of sheet thermal insulation in the form of Energoflex insulating tape.

Installation

The workflow is not too complicated, but it requires following the instructions. You must first view the size table in order to select the material with the desired diameter for working with copper or steel pipes (in different situations).

You will need a set of tools - a measuring tape, a knife, a pencil or pen for marking, a miter box (a carpentry tool for precise sawing, cutting), a hard brush, Energoflex tape and glue.

If the pipeline has not yet been assembled, the following steps will be required:

- the pipe product should be carefully pulled over the pipe;

- if the length of the insulation is not enough, another cylinder is used, which is connected to the first one with glue;

- the joints of the thermal insulation are glued with a connecting tape.

With the pipeline installed, the insulating cylinder is cut along the notch line, put on the pipe and processed with glue and tape.

The thermal insulation must be prepared in advance, the pipe ends must be cleaned and degreased, the glue must be applied to both surfaces. The connection must be carried out 3-4 minutes after applying the adhesive layer. The air temperature must be at least +5 degrees.

This is how quickly and simply the installation of Energoflex thermal insulation is carried out. Moreover, it is durable protection and high quality of service. The main thing is to follow the instructions, and follow the important rules for joining all materials.

For information on how to properly insulate the corners of the pipeline, see the next video.

The comment was sent successfully.