Types of basalt heaters and thermal insulation technology with their help

Basalt insulation is, in its own way, a unique material used in construction. The main advantage of the material is its origin - recycled rocks are used in production.

The technological process of processing raw materials makes it possible to obtain one of the safest types of insulation - basalt.

Material features

Basalt insulation as a natural material is highly valued for efficient energy saving, which is achieved due to a sufficient amount of air in its fibrous structure. Thus, the basis of the insulation is, of course, the created air cushion, which protects against the penetration of cold into the room. Its second name is stone wool. The salient features of the basaltic material are usually considered together. This type of insulation has passed the test of time, for a long time consolidating its position among analogues in the construction market.

Basalt insulation has several main features.

- It does not lose heat, since it is characterized by low thermal conductivity. Basalt material does not consist of strictly oriented fibers. They are located extremely chaotically, which affects the structure and characteristics of the material. A natural cushion of air is created. Thanks to the large number of air ducts or interlayers between the stone fibers, a natural heat insulator is formed. The material at the base has a low coefficient of thermal conductivity (in the range of 0.032 - 0.048 watts per 1 m per Kelvin).

- In some respects, basalt insulation can be compared with a combined material made of cork, foamed rubber, conventional or extruded polystyrene foam. Modern heaters can also be compared taking into account different technical parameters of heat insulators. So, for comparison of similar indicators, you can take 10 cm of basalt insulation with a density of 100 kg per 1 m³ and a ceramic wall 117 cm thick.

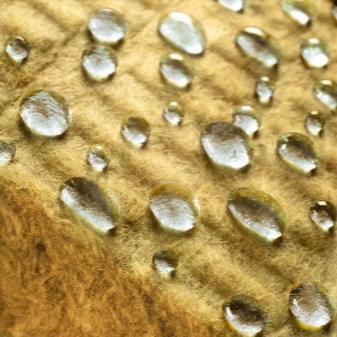

- Does not absorb moisture. Another property of the material is hydrophobicity. When water gets on the insulation layer, moisture does not penetrate inside, but remains on the surface, preserving the thermal insulation properties of the material. If we compare the insulation with mineral wool, it will be noticeable how the last water gradually passes inward, leaving no chance. Such insulation will have much higher thermal conductivity. If you need to insulate a room with a high level of humidity, then you should not use, for example, glass wool, it is better to give preference to basalt insulation. In this case, water, as it were, flows around the fibers of the material, since during production the insulation is impregnated with special compounds (oils).

- Does not interfere with the passage of steam. Vapor permeability is an excellent property of the material, due to which basalt fibers become vapor permeable regardless of density. The moisture contained in the air quietly passes through the insulating layer, not allowing condensation to linger. Vapor permeability is a significant criterion in the selection of material for insulating a room with high humidity.The basalt layer does not get wet, which makes it possible to maintain the desired temperature for a comfortable stay in the room. The vapor permeability of basalt insulation is approximately 0.3 mg / (mh · Pa).

- It is not afraid of fire due to its high resistance to fire. Basalt material (basalt wool) meets fire safety requirements. Fibrous material is classified as non-combustible. Moreover, modern high-quality basalt material is able to resist fire. In order for the melting point to come, the temperature must reach more than +1114 degrees. Therefore, it is often used to isolate various devices that operate at elevated temperatures. Basalt material belongs to the NG group in accordance with the classification of non-combustible materials. Thus, basalt wool is used in buildings of various types and designs, both as a heater and an insulator.

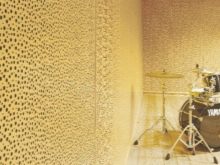

- Practically soundproof. Basalt insulation has such an important property as soundproofing. The material provides a good level of sound insulation, considering its natural origin. Basalt wool can dampen sounds (vertical waves from interior walls) well. This is a great way to isolate yourself from extraneous sounds and nearby noises. Sound waves are absorbed by the material, reducing reverberation.

- Lasting. The random arrangement inside the fibers in the structure of the basalt insulation and some of the fibers in the vertical direction provide the material with a sufficient level of density. Thanks to this, basalt insulation is able to withstand significant loads. Even 10 percent of the deformed surface has a compressive strength with a spread of 5–80 kilopascals. More specific indicators can be obtained depending on the set of conditions and taking into account the grade of the material. The stronger the properties of basalt wool, the better its thermal insulation qualities. Such material will last a long time without changing in size and shape during the entire period of operation.

- Biologically and chemically inactive. Basalt insulation is classified as a material with passive chemical activity. This is one of the main advantages of a building material. It can be laid close to a metal surface without the risk of rust. The insulation does not react to an aggressive biological environment. They do not take rot and mold basalt wool, so it is safe to say that this material has a number of characteristics in terms of strength and resistance to external factors. Even such biological factors as the proliferation of mice and rats will not affect the quality of the insulation, since they will not gnaw through it. The material is boldly used to isolate various technical structures in difficult conditions.

Varieties

Dense basalt material with a fibrous structure has unsurpassed thermal insulation characteristics. Modern basalt insulation varies in type. Although the main difference between the material comes down to the type of fibers: continuous and staple fibers. Diameter remains the main parameter of staple fiber.

It is taken into account when dividing materials into such groups as:

- micro-fine fibers - 0.6 microns;

- ultra-thin fibers - 1.0 microns;

- super thin fibers - 1.3 microns;

- thin fibers - 9-15 microns;

- thickened fibers - 15-25 microns;

- coarse fibers - 50-500 microns.

When choosing an insulating basalt material, you should pay attention to the thickness and length of the fiber, because many quality indicators of the product depend on this.

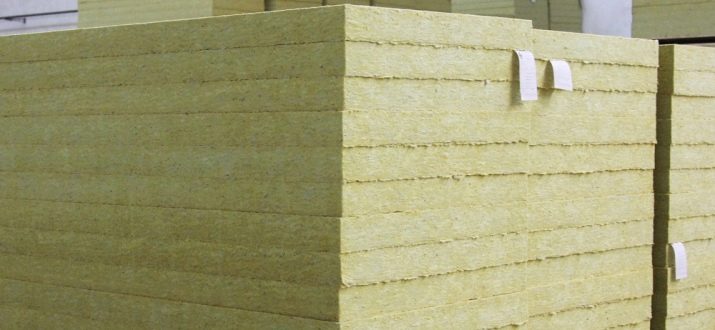

Basalt fiber insulation is also divided into soft, semi-rigid and more rigid versions. On sale there is always a basalt slab, cotton wool, slab or bulk insulation, roll wall insulator, heat insulator in bags or mats.Specific differences relate to the surface - it is a foil or non-foil product that can be easily or difficult to cut with a construction knife. In general, the considered insulation is usually divided into several types.

Foil

Foil tile insulation can significantly reduce heat loss. Today, more and more often houses are covered with foil mineral wool or basalt wool, which is suitable for most types of premises. And also this insulation allows you to save on additional shelter during the heating season. The building material significantly reduces heat loss. It is an excellent thermal insulator consisting of a double protective layer that reflects heat into the room.

Material with a foil surface, in addition to thermal insulation properties, is distinguished by the ability to sound absorptiontherefore provides an additional level of environmentally friendly sound insulation. The service life of the insulation is up to 40 years and more. Basalt (foil) mineral wool is applicable for both interior and exterior decoration. It is used to avoid the possibility of rotting, mold formation, as a hydro and vapor barrier. It is applicable in both non-residential and residential areas. The material is suitable for insulating floors, walls and ceilings, as well as for covering ventilation systems, various tanks.

Mineral wool

The general name mineral wool often implies the use of high quality mineral wool - this is the so-called stone wool, glass wool and slag wool. The increased strength is associated with the dense fiber structure of the material. For the production of basalt mineral wool, two types of rocks are used. It contains no synthetic impurities. Natural origin adds positive qualities to the insulation. The finished building material made of basalt mineral wool is characterized by a small thickness and minimal mutual friction of the fibers (prevents sound vibrations).

The inorganic product is resistant to high temperatures. Basalt wool is fireproof and is used for fire insulation. Non-flammable boards do not shrink. They do not change their original properties even over time. Basalt wool slabs can be used to prevent moisture condensation on the load-bearing walls of a building.

Minvata does not emit dust or various volatile compounds. Building material is considered one of the most efficient and environmentally friendly.

Stone wool

The use of stone wool from basalt rocks is also widespread today. Basalt fiber insulation is a special type of mineral wool. As a raw material for production, gabbro-basalt rock is used. Due to the natural origin, the building material is called stone or mineral. Although we are talking about one product. Basalt is a volcanic rock that is processed at the highest temperatures. After that, upon separation, the product acquires its recognizable fiber.

Properties and characteristics

Basalt fiber insulation acts as a basic thermal insulation. When choosing a material, you should always look at its technical parameters and characteristic features. Stone microfiber actually has a fossilized structure, it stays stable and retains heat for a long time due to a layer of natural ventilation. The material also protects the room from wind and moisture. If additional insulation is required, it is provided with ventilation gaps and waterproof cladding on the outside. Usually, one layer of insulation is sufficient, having a high density and medium size. But often insulation is carried out with insulation in several layers with the presence of overlapping seams in order to increase the technical characteristics.

A special film is laid on top of the basalt mats, which additionally protects the basalt insulation 5 cm thick from condensation. When laying the insulation outside, remember about the sensitivity of the material to drafts and strong winds. In this case, the effectiveness of the heat-insulating material will not exceed 40 percent of the indicators that were originally. The main properties of high-quality insulation, which does not require additional protection, should be called their combination - this is acceptable thermal insulation, a stable level of diffusion of water vapor, sufficient resistance to fungal attack, and a long service life.

The thickness of the insulation layer of 15 cm is sufficient to provide the room with a high level of insulation (heat, hydro, noise insulation) with a film thickness of 20 mm, 30 mm or 100 mm.

When decorating walls and laying basalt insulation, it is worth considering that segments or mats do not adhere well to the wall surface. In this case, the primer will not save the situation. It is better to use a dowel extension. The practical use of basalt fiber insulation is recommended when laying the material on any surface. During the installation process, the material is usually cut into pieces from 20 to 25 cm wide. Thus, the material will be able to maintain its strength and performance.

Initially, the material from natural raw materials has the necessary qualities to cover the walls inside and outside. In addition, the material is used for thermal insulation of chimney exhaust or chimneys, sauna stoves, while their number does not matter. In such cases, there is no need to fear high temperatures. It is worth considering that, depending on the brand, basalt mats, when laid on the ground, draw water from the contact surface. The latter should be treated with a hydrophobic composition with constant contact with moisture, therefore, basalt wool should not be used to isolate foundations, even if the material is characterized by high thermal conductivity, but floors are quite possible and necessary. Basalt insulation perfectly resists shrinkage, because the structure of the material is tough, rodent-proof. Basalt slabs are purchased in packs of several pieces.

Minuses

Thermal insulation material made of basalt fibers, like other types of construction raw materials, in addition to positive properties, can also cause concern. Many do not know if basalt fiber carries any harm. It is worth understanding this in more detail. In the process of basalt fiber production, companies demonstrate the resistance of the insulation to fire. The experiment is carried out, for example, under the flame of a propane or acetylene burner. However, you should not rely entirely on the fire resistance of the material. With a house completely engulfed in fire, it will not work to save yourself, relying on an insulator. Modern high-quality material is really capable of blocking the path to the spread of fire, but this is a matter of time.

Another important point when choosing a natural insulation is that the material is still not devoid of harmful qualities.

It is worth considering them too.

- Thermal insulation material can generate dust when moved, carried, laid or cut, although it does not leave dust marks on its own. It's all about contact with other surfaces as a production. In any case, when working with mineral materials, it is important to observe safety precautions: wear special glasses and gloves, and work in a respirator.

- The material itself does not burn, but in the event of a strong fire or fire, the material emits gases (vapors and resins can be a consequence of the adhesive base).

- Manufacturers of basalt insulation use auxiliary materials to increase the insulating properties - they use phenol-formaldehyde resins, the harmfulness of which is obvious to everyone.

There are also more unpredictable consequences of the use of additional compounds in the production of stone fiber - this is the radiation background of the rock.

It is clear that we are talking about the places of extraction of raw materials, therefore it is not out of place to ask where exactly the rock was mined, whether there could be compounds of heavy metals and isotopes in it. In the process of processing, harmful substances are practically not destroyed. When choosing basalt mats, it is always necessary to monitor the quality of the goods.

How to choose?

Any buyer of building materials is interested in the basalt insulation having the necessary properties in the maximum volume, so it is selected for a number of reasons. Insulation, of course, must meet modern technical requirements. Mineral wool is suitable as the main material for thermal insulation, but today it is better to buy basalt slabs.

When inspecting products, close attention is paid to the density of the material (D).

- Lightweight material - D up to 35 kg / m³ - suitable for light duty structures. For example, for pitched roof structures or when arranging attic and mansard rooms.

- Plates - D 35–50 kg / m³ - are suitable for the construction of structures made of light alloys and for noise insulation when decorating the facades of low-rise buildings.

- Material - D 50–75 kg / m³ - designed for finishing floor surfaces and ceilings, thick internal partitions. In addition, a layer of heat insulator is needed for arranging a three-layer wall structure in low-rise buildings (it is the middle layer).

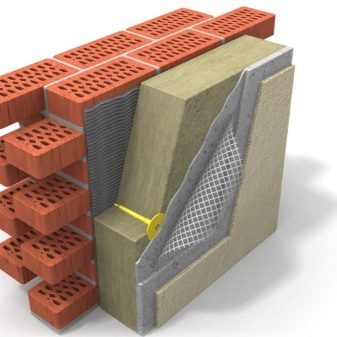

- D 75–100 kg / m³ - used as a heat-insulating material for finishing external walls or when organizing ventilated facades. The high density of the fibers makes it possible to use the material for the installation of two-layer thermal insulation of external walls.

- Plates - D 125–150 kg / m³ - are required for the construction of soundproof partitions. The wall can be thermally insulated under plaster.

- Basalt slabs - D 175 kg / m³ - are used as a layer of independent heat-insulating material when arranging partitions, walls, facades on the basis of reinforced concrete surfaces.

- Plates - D 175–200 kg / m³ - are suitable for soundproofing the floor under the screed.

Scope of application

Properties such as heat and sound insulation are inherent in a number of basalt fiber insulation with a rigid fiber structure. Thermal insulation in a modern design using the technology of laying tile insulation is applicable for decorating walls, attics, roof structures, building façades, pipes. Mineral wool (or basalt wool), slabs and basalt rolls will be needed when installing heat-insulating layers for processing various elements of buildings (wooden, brick, aerated concrete, concrete), for decorating objects of complex configuration (using special equipment, when laying pipelines). When laying basalt wool in damp rooms, many builders resort to additional windproof, waterproof and vapor barrier materials.

Basalt material is applicable for residential and non-residential buildings, many parameters depend on the manufacturer and brand of the product, for example, "Basalit" shows one of the best sales results in the construction market for modern insulation materials.

Installation methods

To avoid heat loss at home, it is important not only to choose the material, but also the correct installation. Stone wool (as usual, builders call basalt insulation) is suitable for covering the facade, walls or for the roof. Layers are stacked in stages and sequentially. Professional skills do not play a special role here. The main thing is to carry out the installation of the slabs, achieving the exact joining of the segments with each other. Even a little construction experience and a creative approach to business will allow you to complete the entire range of installation work on laying basalt insulation exactly and on time.

It is necessary to purchase rolls or plates in advance, as well as stock up on the following tools:

- insulation (basalt material, for example, in the form of slabs);

- glassine;

- wooden slats;

- construction knife;

- grinding float;

- polyurethane foam;

- nails and hammer.

Initially, it is necessary to close the gaps, cracks and crevices found on the surface to be treated. For this, construction foam is most often used. Although, the roughness is often sealed with felt or tow as a cheap option. Further, waterproofing is done, a layer of vapor barrier is laid so that condensation does not remain on the insulation. Natural ventilation is provided for greater durability and quality characteristics of the product. If the roof is insulated from inside the room, then a special film is used as a vapor barrier.

The lining of vapor barrier material provides natural ventilation of the space and retains water vapor. The vapor barrier is glassine, foil or film. A construction stapler is used for fasteners. For example, if the waterproofing of a house is carried out under the roof, then the necessary barrier is obtained, which does not allow moisture to penetrate into the room. The installation of the thermal insulation layer is usually carried out on the rafters with a stapler.

Under a dense layer of basalt slabs, a crate is installed, which is made of thin wood slats. For fastening the insulating material, in addition to a special stapler, screws, mastic and construction glue are used.

It is worth considering, using the example of a roof, how the installation of basalt insulation in the form of slabs is carried out.

- First, a metal cornice is built on the house, it is attached to the supporting wall with dowels. Due to the eaves, you can reduce the load of the insulation and at the same time protect the material from external influences.

- On the prepared cornice, the insulation plates are fastened using polymer-cement glue for reliable fixation to the base of the wall. The adhesive is accurately and evenly distributed over the entire surface of the basalt slab. Then the material is pressed tightly against the base of the wall (on the structure). It is better to install basalt material (slabs) from the bottom and up, moving from right to left. This ensures a uniform coverage. And it's much more convenient to work this way. First, whole slabs are mounted, and then the remaining areas are covered with cut pieces from the slabs.

- After the main work, the surface of the wall is leveled with a sanding float. This stage of work is necessary for the installation of a ventilated facade in the future.

The process of installing basalt insulation does not differ in complexity and energy consumption. Nevertheless, to obtain the result, it is necessary to follow all the advice on the choice of material in terms of density and size, on the choice of tools and the nature of the work. The technique of performance here is quite simple for even a beginner to handle. At the same time, do not forget that the maximum assessment of the quality of house insulation is possible only in winter.

The pros and cons of basalt wool are in the next video.

The comment was sent successfully.