Reflective insulation: technical characteristics and scope

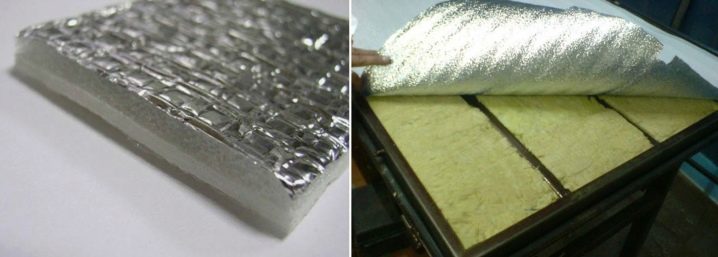

Reflective insulation is a two-layer material consisting of a base and a reflector. A variety of thermal insulation is used as a base, for example, foamed cellophane, mineral wool, expanded polystyrene. The dural layer is applied as a screen. He directly stores heat. The sheet functions as a mirror, reflecting more than 85% of thermal radiation, and does not allow it to leave the thermal insulation in any way.

Peculiarities

Reflective insulation has the following important technical characteristics:

- temperature range of application - the higher the better;

- thermal conductivity coefficient - from 0.038 to 0.051 W / m · ° С;

- insulation thickness;

- reflectivity coefficient - from 90%;

- vapor permeability - in rare cases, it exceeds 0.001 mg / m · h · Pa;

- flammability group - G1-G4 (under conditions of ignition, the first variety is acquired).

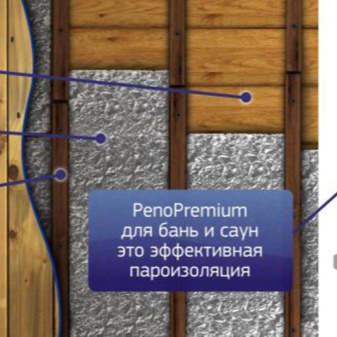

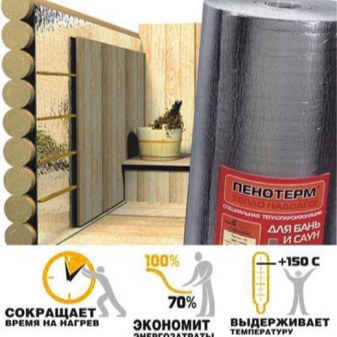

When choosing reflective insulation, it is necessary to use the type of base suggested by the manufacturer and take into account its purpose. Thus, using type B material inside a building is not only unprofitable from a financial point of view, but even risky: the effect of the bath will be felt from the very first day of operation. For saunas, it is preferable to select brands that have a wide thermal range of applications (with a border above 90 degrees).

In addition, reflective insulation is used for:

- insulation of walls, basements and cellars, ceilings and roofs;

- improving the thermal resistance of some structures (double-glazed windows, doors);

- protection of special equipment (refrigeration systems, plumbing units, ventilation);

- reflection of heat from heating radiators.

In addition, it is often used as a packaging material for some devices.

There are several key benefits of reflective insulation.

- Possibility to reduce costs: during insulation, you do not need to use a large number of materials. For comfortable living conditions in the building and minimizing heating costs, brick walls with a width of 55 cm should be increased.

- When the walls are narrowed, the load on the base of the house is significantly reduced, which makes it possible to reduce its volume. This is a new economy.

- The simplicity of the design of thermal insulation. Its installation is absolutely easy.

- Such insulation is harmless and environmentally friendly. For its manufacture, the same raw materials are used as for the production of products in contact with food.

- Due to the low weight of the material, it is practical to transport it.

Thanks to lightweight cells in polyethylene foam, it has a high thermal conductivity. The heat that has penetrated into the building is not able to go outside - it remains inside. Foil material is capable of withstanding significant overloads. This material is very durable (if installed correctly). In addition, it is very easy and comfortable to use. On the walls or ceiling covering, it is strengthened using a special construction stapler. There is an insulation with a bonding cover. The layer of thermal insulation with a reflective layer based on polyethylene foam can be up to 20 mm.

The main disadvantage of this thermal insulation is its softness, which is why it cannot be covered with plaster and wallpaper.

For the purpose of fixing, any convenient method can be used. Self-adhesive types of fixing have good reviews. Unlike many vapor barrier films, as well as with reflective elements, foam insulation is located tightly, rather than overlapping. However, this does not mean at all that the seams do not need to be closed in any way, on the contrary, this stage is considered necessary. The main material for sealing is a special duralumin tape.

Today reflective and heat-reflecting porilex of the Mosfol brand is in demand.

Views

There are 3 types of reflective insulation, labeled A, B and C.

- If the name of the insulation contains the letter A, this means that only one of its surfaces is covered with a reflector. It is used to insulate almost any surface, and its width can be different. It is laid with the foil side inside the room.

- Thermal insulation with letter V covered with aluminum foil on both sides. It is usually used for decorating freezers due to the fact that the cold will not come out and the heat will not penetrate inside. Also, this material is used to keep different temperatures in rooms.

- Insulation with letter WITH in the name - it is a reflective thermal insulation with a self-adhesive layer. One of its sides is covered with aluminum foil, and the other - with an adhesive mixture and a protective film. This type of insulation is considered the most convenient for installation.

Principles of use

Reflective insulation can only be used as an additional (auxiliary) means of insulation. For objectivity, it must be said that in certain cases, the reflecting TIM can be both the main and even the only means of insulation. For example, when insulating air ducts of ventilation systems. But in standard private buildings there is no such need. Due to its characteristics, reflective insulation can be used as a vapor and moisture barrier material indoors.

In the case of using TIM, you need to understand some points and nuances of its use. It is forbidden to use reflective TIM specifically for waterproofing works. Reflective TIM should be used as general insulation (moisture, steam and noise), and if we take into account its environmental friendliness, then it has a significant advantage in comparison with conventional materials when laying, for example, indoors.

When insulating ceilings, there are almost no restrictions - you can use it everywhere.

- Energy-saving requirements for insulation of ceilings are undoubtedly higher than, for example, for walls, and an additional layer will not interfere.

- Inside the room, warm air always moves upward, that is, the boundary conditions for the operation of the ceiling are also worse in comparison with the walls of the room.

With additional wall insulation, reflective TIM can not be used for all rooms. For example, in the absence of good ventilation, you can get a steam room in which it will simply be impossible to be. When performing work with reflective TIM, it is necessary to take into account that it works correctly only in the presence of an air gap and mechanical protection (usually this is done in a constructive way). Because of this, installing TIM on the ceiling or wall, and then pasting the wallpaper, will not work.

How to insulate?

Ceilings

At the initial stage, you need to understand how much material is needed and how to fix it. Having calculated the area of insulation, add 10 cm on each side and get the required amount of material. It can be easily cut with a knife. When cutting out, you need to make a margin (at least 3-4 cm) for future installation and adjustment of the material according to the structure and exclusion of excess.

Thermal insulation is installed with a reflective layer inside the room. It is necessary to overlap the walls - better with a margin. All excess can then be easily removed with a knife.If the ceiling is wooden, then TIM laying on the ceiling can be done with a construction stapler. In this case, you need to immediately correctly set the material in relation to the building structures: an inaccuracy during installation of 1 cm at the beginning can grow into 10 and 20 cm at the end. The distance between the brackets is set in the course of work. The main condition is the absence of waves on the insulation.

Strips of reflective TIM should be laid end-to-end, and then glued with a special (reflective) tape.

Walls

For maximum efficiency of wall insulation, you need to leave an air gap of 15–20 mm from the foil surface. Reflective insulation with conventional insulation is effectively used for multi-storey and low-rise structures. At the same time, the thermal protection of the walls increases rapidly without changing their volume.

Usually, when insulating walls indoors, two installation options are used. In the first option, two air gaps are left: between the outer wall and the insulation, between the insulation and the wall cladding, for example, gypsum plasterboards. In the second version, one gap is provided: between the outer wall and the thermal insulation. In this case, use the material marked A. The foil must be turned inside the room.

Roof

This work is usually done using mineral wool. Let's start with the materials for the roof: waterproofing that fits under the roof, a heat insulator with a thickness of more than 15 centimeters, a vapor barrier. But it must be taken into account that the effectiveness of such a combination is only 85%.

What can be done? Only thicken the thermal insulation layer. There is only one way: instead of a vapor barrier material, use penofol, the thermal protection efficiency of which is already 97%.

The best way is to lay the insulation from the inside even at the stage of roof construction. That is, after installing the vertical struts, it is necessary to overlap the waterproofing material over them. Then the lathing and roofing material are stuffed.

The remaining work is done from the attic or attic space. Insulation is laid in the space between the rafters, on top of which penofol is stuffed. After that, you can close it with various finishes (lining, plywood).

How to choose?

When choosing a material for insulating building structures, it is imperative to take into account some important points.

- First of all, it is temperature range of application... For most of the premises, both residential and commercial, almost any reflective TIM is suitable. For saunas, baths and other premises with high levels of humidity and temperature, it is desirable to use a material based on polypropylene, which has a wide range of use (up to +150 degrees). From the point of view of "price-quality", in most cases, the optimal is the use of reflective TIM having a thickness of 4 mm. Manufacturers themselves declare this.

- The reflectivity of TIM also depends on the composition. Aluminum foil coating is preferable to metallized lavsan film not only in reflectivity, but also in temperature range and mechanical parameters. However, in some cases, this thermal insulation may be limited in use due to the fact that the aluminum coating is electrically conductive. The quality of the reflective TIM also depends on the technology of their manufacture (cross-linked or non-cross-linked polyethylene). There is physically and chemically cross-linked polyethylene.

In practice, when buying TIM, you can use the following trick: if you look through the material at a bright light, you can clearly see the quality of the material (the presence of stripes, uniformity, spots and their number).

Comparing materials with each other, you can find the best option for yourself. Sometimes it happens that the rise in the cost of a material by a few rubles can be offset by its better quality.

Reflective insulation greatly reduces the heat loss of the building and thereby minimizes heating costs and the amount of fuel used. Before buying a material, you need to look at its quality certificate, since some manufacturers instead of aluminum foil apply a thin layer of metal to the surface of the insulation. Such thermal insulation, based on the reviews of professional builders, has significantly worse characteristics, and its service life is also shorter. If a roll of insulation has a very low price, then for sure it is a fake.

For an overview of PenoHome reflective insulation for walls, see the video below.

The comment was sent successfully.