Penoplex "Comfort": characteristics and scope

Insulating materials of the Penoplex trademark are products from extruded polystyrene foam, which belongs to the group of modern heat insulators. Such materials are most efficient in terms of thermal energy storage. In this article we will consider the technical characteristics of the Penoplex Comfort insulation material and talk about the scope of its use.

Features: advantages and disadvantages

Previously, such a heater was called "Penoplex 31 C". The high technical characteristics of this material are largely determined by its cellular structure. Cells ranging in size from 0.1 to 0.2 mm are evenly distributed throughout the entire volume of the product. This distribution gives strength and a high level of thermal insulation. The material practically does not absorb moisture, and its vapor permeability is 0.013 Mg / (m * h * Pa).

The insulation manufacturing technology is based on the fact that polystyrene foams, enriched with an inert gas. After that, the building material is passed under pressure through specialized press nozzles. Plates are manufactured with a clear geometry of parameters. For a comfortable joining, the edge of the slab is made in the shape of the letter G. The insulation does not contain harmful substances, therefore, the installation of the material can be performed without using protective equipment.

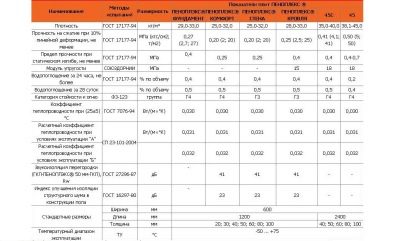

Specifications:

- thermal conductivity index - 0.03 W / (m * K);

- density - 25.0-35.0 kg / m3;

- long service life - more than 50 years;

- operating temperature range - from -50 to +75 degrees;

- fire resistance of the product;

- high compression rate;

- standard dimensions: 1200 (1185) x 600 (585) x 20,30,40,50,60,80,100 mm (slabs with thickness parameters from 2 to 10 cm are used for internal thermal insulation of a room, for external finishing - 8-12 cm, for the roof - 4-6 cm);

- sound absorption - 41 dB.

Due to its technical characteristics, the thermal insulating material has the following advantages:

- high resistance to chemicals;

- frost resistance;

- large assortment of sizes;

- easy installation of the product;

- lightweight construction;

- insulation "Comfort" is not exposed to mold and mildew;

- Penoplex is well cut with a paint knife.

Penoplex "Comfort" is not only not inferior to more popular insulation materials, but even surpasses them in some respects. The material has the lowest thermal conductivity and practically does not absorb moisture.

Negative customer reviews about Penoplex Comfort insulation are based on the existing material shortcomings:

- the action of UV rays has a detrimental effect on the material, it is imperative to create a protective layer;

- insulation has low sound insulation;

- oil-based dyes and solvents can destroy the structure of a building material, it will lose its thermal insulation qualities;

- high cost of production.

In 2015, the Penoplex company began to produce new grades of material. These include "Penoplex Osnova", "Penoplex Foundation", etc. Many buyers are wondering about the difference between heaters "Osnova" and "Comfort". Their main technical qualities are practically the same. The only difference is the coefficient of compressive strength. For the “Comfort” insulation material, this indicator is 0.18 MPa, and for “Osnova” it is 0.20 MPa.

This means that Osnova penoplex is able to withstand more load. In addition, "Comfort" differs from "Basis" in that the latest variation of insulation is intended for professional construction.

Where is it used?

The operational qualities of the Comfort Penoplex allow it to be used not only in a city apartment, but also in a private house. If we compare the insulation with other building materials, then you can notice significant differences. Similar insulation products have a narrower specialization of application: thermal insulation of walls or roofs.

Penoplex "Comfort" is a universal insulation, which is used for thermal insulation of balconies, foundations, roofs, ceiling structures, walls and floors. Also, the insulation is perfect for thermal insulation of baths, pools, saunas. Insulation "Penoplex Comfort" is used both for internal construction works and for external ones.

Almost any surface can be trimmed with "Comfort" insulating material: wood, concrete, brick, foam block, soil.

Slab sizes

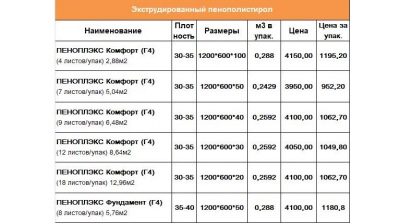

Extruded insulation is produced in the form of plates of standard parameters, which are easy to install, and also easy to cut to the required size.

- 50x600x1200 mm - 7 plates per package;

- 1185x585x50 mm - 7 plates per pack;

- 1185x585x100 mm - 4 plates per pack;

- 1200x600x50 mm - 7 plates per package;

- 1185x585x30 mm - 12 plates per pack.

Installation tips

Insulation of external walls

- Preparatory work. It is necessary to prepare the walls, clean them from various contaminants (dust, dirt, old coating). Experts recommend leveling the walls with plaster and treating with an antifungal agent.

- The insulation board is glued onto a dry wall surface with an adhesive solution. The adhesive solution is applied to the surface of the board.

- The plates are mechanically fixed by means of dowels (4 pcs per 1 m2). In those places where windows, doorways and corners are located, the number of dowels increases (6-8 pieces per 1 m2).

- A plaster mixture is applied over the insulation board. For better adhesion of the plaster mixture and insulation material, it is necessary to make the surface a little rough, corrugated.

- Plaster can be replaced with siding or wood trim.

If it is impossible to perform thermal insulation from the outside, then the insulation is mounted inside the room. Installation is carried out in a similar way, but a vapor barrier is placed on top of the insulating material. Foil-clad plastic wrap is suitable for this purpose. Next, the installation of the gypsum board is performed, on which it will be possible to glue the wallpaper in the future.

In the same way, work is carried out on the insulation of balconies and loggias. The joints of the plates are glued with special tape. After installing the vapor barrier layer, the joints are also glued with tape, creating a kind of thermos.

Floors

Warming of floors with "Comfort" foam under the screed in different rooms may differ. The rooms located above the basements have a colder floor, therefore more insulation layers will be required to carry out thermal insulation.

- Preparatory work. The floor surface is cleaned of various contaminants. If there are cracks, they are repaired. The surface should be perfectly flat.

- Prepared floors are treated with a primer mixture.

- For those rooms that are located above the basement, it is necessary to perform waterproofing. Along the perimeter of the room in the lower part of the walls, an assembly tape is glued, which compensates for the thermal expansion of the floor screed.

- If there are pipes or cables on the floor, then a layer of insulation is first laid. After that, a groove is made in the slab, in which the communication elements will be located in the future.

- When the insulation boards are laid, it is necessary to install a reinforced polyethylene film on top of the layer. This is necessary to protect the insulation material from moisture.

- A reinforcing mesh is laid on top of the waterproofing layer.

- The preparation of a cement-sand mixture is in progress.

- Using a shovel, the solution is evenly distributed over the entire floor surface, the layer thickness should be 10-15 mm. The applied solution is compacted with a metal roller.

- After that, the reinforcing mesh is pryed with your fingers and lifted. As a result, the mesh should be on top of the cement mortar.

- If you plan to install a floor heating system, then its installation must be carried out at this stage. Heating elements are laid on the surface of the subfloor, the cables are fixed to the reinforcing mesh using clamps or wire.

- The heating elements are filled with mortar, the mixture is compacted with a roller.

- Leveling of the floor surface is performed using special beacons.

- The screed is left for 24 hours to harden completely.

For the advantages and disadvantages of insulation, see the video below.

The comment was sent successfully.