Everything you need to know about the vice

In the course of machining parts, it is required to fix them in a fixed position, in this case a vice is used. This tool is offered in a wide range, making it possible to perform work of the most varied degree of complexity.

What it is?

A vise is a tool, the basic purpose of which is to fix workpieces in a static position during planing, sawing, as well as drilling and other types of processing. The design of the tool includes several details.

- Base - the body together with the base plate, the latter is needed to install the vice on a workbench, machine or table. In some cases, it can be equipped with an anvil. The type of fastener is usually vacuum (on suction cups), magnetic or bolted.

- Sponges - are mobile and static. The latter act as a base element; in this case, the clamping of the part is carried out by moving one jaw towards the other. Each sponge has removable pads - they are called "cheeks". Their inner surface is flat or corrugated. Products of the first type are intended for clamping soft, the second - for hard. In this case, the cells of the corrugated pattern can have a pyramidal shape or consist of horizontal and vertical grooves cut along the entire length.

- Clamping screw - a special mechanism directly responsible for moving the sponge has a rotary handle. Passes through from the vise itself to the handle, allowing rotation without the use of wrenches or similar tools.

Some types of vise may have their own design features. For example, some models have hydraulics instead of a mechanical screw. Others have several pairs of sponges, they are placed on top of each other. Each type of variety has its own scope.

Species overview

Vices are presented in a wide variety of models, differing in their structure and functionality. Vices can be household, self-centering, multifunctional, floor-standing, portable, with or without a drive. The most widespread are mechanical devices, in which the clamp is made due to the application of physical efforts. Such models are conventionally divided into several groups.

- Screw - the design provides for a running rifle that runs smoothly along the entire length of the vice. Usually made with trapezoidal threads.

- Keyless - the lead screw moves through the spring-fitted part. Differs in mobility in the transverse plane. At the moment of pressing, the screw is released from its clutch, so it can be moved freely without rotation.

- Quick release - such models open and close without the use of a screw. The design contains a special mechanism with a lever or trigger, it is responsible for the operational adjustment of the position of the jaws.

- Eccentric - are used when it is necessary to quickly tighten the parts. During the operation of the tool, the jaw moves freely until the eccentric is clamped.

To increase the processing speed, other types of vice are also used.

- Pneumatic - here the convergence and divergence of the jaws is ensured by a special mechanism with cameras and built-in diaphragms. The design of such a tool provides for a pneumatic line connected to an air-type compressor.This device allows you to clamp workpieces in a couple of seconds without any effort.

- Hydraulic - screw-type tools with built-in hydraulic booster. This category also includes models whose principle of operation is reminiscent of a jack with a plug-in hydraulic pump.

Depending on the design features, tools are divided into locksmith, carpentry, as well as manual and machine tools.

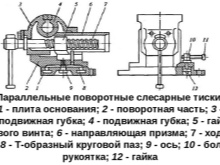

Locksmiths

Locksmith devices are made of metal, all the elements in it are solid and dense. Soft elements are not provided in the design. The vise is mounted on a table, workbench, or an ordinary stand. Such a device can be fixed stationary or rotated, depending on this, you can process the part at any angle. The width of the jaws for such products varies in the corridor from 50 to 200 mm. They form a gap to hold work pieces up to 150 mm thick. Locksmith's vice is distinguished by a compact anvil, it is in demand for leveling workpieces with hammer blows.

The vice provides for a slight backlash that occurs when the jaws move. But this is not critical, since such tools are used mainly for rough work. The advantages of these tools include structural reliability and fixation strength. They are distinguished by relatively compact dimensions, while the body is made of cast iron or steel, therefore such discs are resistant to any mechanical stress.

Of the minuses of plumbing fixtures, the presence of backlash can be distinguished, while during the operation of the vice, it begins to increase. The most vulnerable point of this design are recognized lock washers... As practice shows, they wear out rather quickly and require constant replacement. That is why it is inconvenient to fix long workpieces with sponges of small width. If the workpiece is heavy, one end of the part may drop.

To prevent this from happening, you will have to tighten the screw from time to time during work. If the jaws were larger, then, with equal force, they would provide the most reliable fastening due to the increased frictional force. However, there is no such vice among locksmith products.

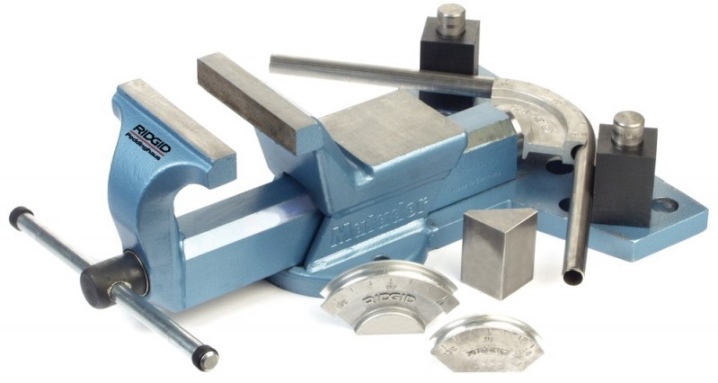

Machine tools

Another popular type of machine vice is machine tools. These are devices of increased accuracy, they do not have a screw. Rotation is performed over a certain area in a single axis with additional sections of fasteners, therefore, the jaws do not provide for backlash. Such devices are relevant in industrial production. Usually they are mounted on workbenches, while the stand can have several adjustment axes - thanks to this, the workpiece can be turned at any inclination both in the vertical and horizontal directions.

Machine-type vices are characterized by increased pressure. The design provides for wide jaws, they allow you to squeeze and hold the most elongated and heavy workpieces. Their body is made of stronger materials than those of locksmith models. However, such devices have their own flaws. They compress the part too much.

If you tighten the screw with force, then traces of sponges will be printed on the workpieces. Of course, this cannot be called a serious disadvantage, but when working with such a vice, it is important to be careful.

The advantage of such a vice is the reliability of the design. They can be easily disassembled, lubricated and cleaned if necessary. There are almost no backlashes in them, and the handle is covered with santoprene or leather. This prevents slipping and freezing of hands in the cold. The disadvantages of the model include its small size, which makes it impossible to process large parts.

Some vices provide special functionality.

- Inclined - products in which a hinge joint is provided. Allows you to change the angle of the part along the vertical axis.

- Globe - two-axis vise, in which the inclination of the workpiece placement can be changed by turning in the horizontal and different directions.

- Articulated - the basis of the structure is a ball pressed into a cage. This allows, if necessary, to turn the device at any angle in different directions.

- Coordinate - in such discs, workpieces can move horizontally in two directions.

Carpentry

Carpentry vice is designed to hold wood blanks. Their characteristic feature is in wide lips, which makes it possible to increase the pressure area and ensures that there are no imprints on the surface of the workpieces being processed. Models used in carpentry are usually made of dense wood - in the overwhelming majority of cases, it is beech, oak or ash. They are fixed to the table with screws.

The advantage of these models is the ability to process soft workpieces. But for fastening rigid ones, they are not suitable. If you clamp metal in such a vice, you can damage the jaws.

Manual

Hand-held devices are needed to ensure the immobility of small-sized workpieces that are difficult to hold in the palms. In the traditional design, such options are represented by a pair of steel jaws, fastened with a bridge. A clamping screw is provided on the rear side in the middle of the structure. Outwardly, they look more like ticks. Another way of execution is a vice in the form of a clamp. They resemble snap-nose pliers with dead-center levers and a simple lever mechanism. Such products are in demand when modeling miniature copies of aircraft, cars or boats. They are also in demand in the jewelry industry.

These tools look diminutive and can easily fit even in a work jacket pocket. In this case, such tools should not be confused with compact locksmith tools. The latter in any situation should be fixed on some surface, while the hand ones do not require this - they are simply held in their free palm like a handle, clamping a small part. At the same time, the other hand performs processing with a file, emery or other tool.

Machine tools are universal or designed specifically for the requirements of a particular type of machine tool.

- Drilling - used for clamping elements in a drilling machine.

- Milling - facilitate milling. Such parts can change the angle of inclination and rotate.

- Curved - are in demand for machining of high-alloy steel products, represent a high-precision tool. They are in demand in measuring, as well as grinding and polishing installations.

- Sinus - allow processing at different angles.

- Turning - required for mounting on turning installations.

Materials (edit)

Depending on the material of execution, the vice can be as follows.

- Metallic - usually these are cast-iron devices, aluminum, duralumin, and steel are sold a little less often.

- Wooden - are used exclusively in conjunction with a joiner's workbench, less often they are an independent design. They are needed for fixing wooden blanks in a static state. All elements in them, with the exception of the clamping mechanism, are made of durable, but soft types of wood, for example, pine.

Tool sponges are made from non-ferrous metals or wood. Hard rubber is used less often. Some manufacturers offer tempered sponges in steel grades up to 45 HRC. Plastic tools are rare because they are impractical and short-lived.

Dimensions and weight

Taking into account the huge variety of varieties of vice, we can mention the impressive range of their dimensions. The standard tool comes in the following sizes. Small:

- length - 280 mm;

- height - 160 mm;

- the height of the jaws - 40 mm;

- jaw stroke - 80 mm;

- weight - 10 kg.

Average:

- length - 380 mm;

- height - 190 mm;

- jaw height - 95 mm;

- jaw stroke - 145 mm;

- weight - 15 kg.

Large:

- length - 460 mm;

- height - 230 mm;

- jaw height - 125 mm;

- weight - 30 kg;

- jaw stroke - 170 mm.

There are also special sizes that are much larger than those listed above. For example, the classic T-250 vise is 668 mm long and weighs 60 kg. Their jaws are 240 mm wide and rise 125 mm.

The following sizes are typical for a chair vice:

- length - 380-400 mm;

- width - 190-210 mm;

- height - 190-220 mm;

- sponge stroke - 130-170 mm;

- the height of the jaws - 60-75 mm;

- weight - 13-20 kg.

The length of hand-held models varies from 30 to 100 mm, the width is from 6 to 5 mm, and the height is 100-150 mm.

Popular manufacturers

In the market for household and professional tools, German and American models are especially popular; products of domestic manufacturers are also of good quality. According to the description of users, the rating of the best manufacturers includes well-known foreign companies:

- Wilton;

- Trition;

- TOPEX;

- BOVIDIX;

- Ombra;

- Irwin;

- Biber;

- NEO;

- Stanley;

- FIT;

- RIDGID;

- NORGAU;

- WEDO;

- REKON.

Russian-made vices are highly valued:

- "COBALT";

- "Business of Technics";

- "Caliber";

- "Anchor";

- "Stankoimport".

In stores, you can find products made in Korea or China, they are distinguished by their low price. However, as practice shows, such a tool is short-lived and has to be changed quickly. Therefore, the use of such a vise makes sense only if you plan to clamp the elements at a time and subsequently do not intend to do this work.

Nuances of choice

Before choosing a vise, you need to determine what you need them for - for a house or garage, for soldering, drilling or for precision work. This largely determines the requirements for them. When choosing a vice, it is necessary to focus on the presence of backlash. If the proposed product has them, you do not need to take it, soon it can turn into a rather serious problem.

When choosing the right product, you need to proceed from the fact that which parts you will be clamping... This will allow you to select the material for the production of the vice and the optimal gripping parameters.

Specify separately the type of fixation of the pads on the jaws, they are fixed with screws or with rivets. The rivets give you a stronger hold, but you won't be able to quickly change the pads if necessary.

The comment was sent successfully.