All about the blacksmith's vice

Peculiarities

Blacksmithing is an occupation that is always surrounded by a certain glory and respect. But those who are going to do it should properly study the future field of activity. It is especially important to know everything about blacksmith's vice.

First, you need to figure out what a blacksmith's vise is and what they are. Like a similar device used in household work, in locksmith and carpentry workshops, they are designed to rigidly fix one or another detail. This significantly increases the possibilities of processing workpieces in various ways. They can be easily drilled, sawed, planed, sanded and so on, without fear that the semi-finished product will budge. Specifically, blacksmiths use a vice to:

- flexible;

- twisting;

- disembarkation.

There is no need to expect any special design complexities from a forge vise. But at the same time they have certain differences from those used by carpenters and locksmiths. So, joiner's vice, which is most often made of wood, is completely unacceptable. And even ordinary metal will not work - be sure to need products made of heat-resistant alloys... Typically, the vise accomplishes its task thanks to a pair of plates arranged mutually parallel.

The locking mechanism helps to adjust the contact force. A special block is provided for quick manual adjustment. One of the plates is fixed as rigidly as possible, while the other can be moved. It is also worth noting that forge vices are usually heavier and outwardly coarser than those used in more "delicate" industries.

Varieties

In the smithy you can find, we will notice, and the most ordinary locksmith's vice. Simply because individual locksmith operations are performed there. Such a tool is suitable for a huge number of tasks. Allocate:

- small;

- medium;

- large locksmith vice.

Their parameters are as follows:

- length - 0.29, 0.372 and 0.458 m;

- height - 0.14, 0.18 and 0.22 m;

- the height of the sponges - 0.05, 0.07, 0.09 m;

- sponge stroke - 8, 12.5, 16 cm;

- weight - 8, 14 and 27 kg.

But it should be borne in mind that some models may be much larger than standard samples... The classic version of the vice - T-250 - already reaches 66.8 cm in length. Their weight is 60 kg. The jaws protrude 0.125 m.The width of these jaws is 0.25 m.

The situation is different with the chair vice. The spread of their mass is from 13 to 19 kg. The movable jaw can move 0.12-0.16 m. The length of the chair vice is 0.37-0.4 m. Their width is 0.18-0.2 m, and exactly the same height.

Concerning conventional hand vices, then their length varies from 0.022 to 0.09 m. In this case, the width can reach 0.006-0.045 m, and the height is 10-15 cm. An important role is played by the compressive force that the vice can develop. It is determined by engineers by the force that will still allow the rigidly blocked workpiece to be moved. For locksmith vices, the compression force varies from 15 to 55 kN, and for chair vices, this figure is 20-30 kN.

Separately, it should be said about parallel vise. They are, in turn, divided into swivel and non-swivel groups. Already the name suggests that the movement of the sponges occurs parallel to each other, which allows you to get away from a number of weaknesses characteristic of the chair structure. A circle is located at the bottom of the rotary device, which is rigidly attached to a workbench or other support.

You can move the vice along this circle to any angle, and then they are easily fixed in the chosen arbitrary position.

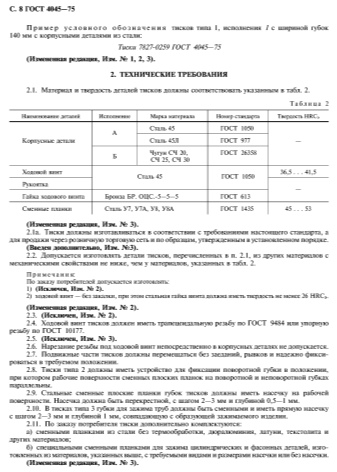

It is useful to consider and vise gradation in accordance with GOST 1975... It covers all models with a jaw width of not less than 0.063 and not more than 0.2 m. The standard highlights fixtures:

- general profile;

- with swivel jaw;

- with 1 or more additional jaws;

- at idle speed or at normal idle speed.

Selection recommendations

Even an advanced blacksmith shop must have at least one locksmith vice of medium size group. They will successfully complete most household tasks. Important: powdered metal products are not suitable. It is better to focus on models cast from steel or cast iron. For professional use in full, it is advisable to use an eccentric or quick-release device.

Steel vise with anvil has increased strength. They make it possible to process workpieces with additional blows for a long time. It is useful to check if the pads on the jaws are removable. The opening distance of the jaws is another point that is fundamentally important for professional work. It is this property that determines which parts can be fixed in a vice.

When visiting a store, you need to carefully consider whether the device looks good.

Important: it's worth trying it in action. A quality tool should not jam or move too quickly and easily.

The lead screw is normally equipped with a safety mechanism, otherwise the design will be unreliable. When the jaws are closed, the divergence of adjacent surfaces can be no more than 0.5 mm.

Widening at the edges of the crank should not allow the lead screw to go somewhere or get stuck, that is, their diameter should be significantly smaller. When the linings are removed from the jaws, parallelism is not lost with a good tool. Careful inspection and careful tapping will reveal if there are any cracks in the bed. Of course, the vice follows also check for various backlashes, and it is best to go shopping to trusted places.

All about the blacksmith's vice for artistic forging, see the next video.

The comment was sent successfully.