Grout Litokol: types, features, instructions for use

It is difficult to imagine renovating a bathroom or kitchen without using wall and floor tiles. The finishing touch of the tile application is the use of grout, which gives an aesthetic appearance and protects against premature lagging of the material from the surface. One of the leaders in this market is Litokol brand products. Its features and advantages will be discussed below.

Benefits of brand products

All Litokol brand products meet the highest requirements for the production of building mixtures. The fact is that the company was founded in Europe, namely in Italy, where advanced equipment for the production of dry mixes is used. Since only high quality raw materials are used in the creation of all brand products, this ensures a long service life of all building mixtures.

Litokol grouts have an important property - versatility. This means that you can use the grout for both indoor and outdoor use, and the result will be equally great. Conveniently, the same Litokol grout can be used for laying various types of materials: both tiles and porcelain stoneware.

Insecurity and resistance to damage and UV rays are also the strengths of the brand's products. Thanks to the use of Litokol grout, you can postpone the next repair, because the joints between the tiles will retain their original color after a very long time.

Specifications

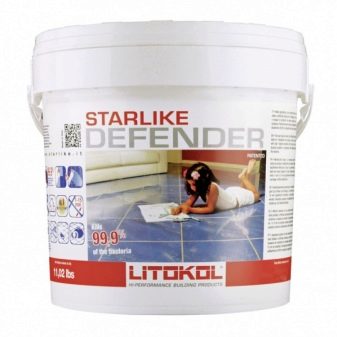

The technical characteristics of Litokol grouting materials are very diverse. Each variety performs its function and has certain properties. For example, STARLIKE DEFENDER epoxy grout is safe, bactericidal and approved for use in hospitals, swimming pools or various warehouses. Another significant advantage of Litokol epoxy grout is that it is odorless, which is ideal for work in poorly ventilated areas.

The technical characteristics of cement grouts are usually distinguished by their resistance to mechanical stress and deformation. Cement trowels LITOCHROM 1-6 and LITOCHROM 3-15 can boast of such characteristics. In addition, they have increased resistance to abrasion and fading, which is great for indoor and outdoor use.

When it comes to polyurethane grouting mixes, these Litokol mixes are ideal for working in wet areas. They have increased elasticity and a water-repellent element, as well as high resistance to various aggressive chemical environments. Ideal for trowelling in areas such as:

- "warm floor;

- stairs and platforms;

- building facades;

- rooms with normal or high humidity.

Variations in the composition and form of release

Litokol grouting mixtures are presented in three main types: cement, epoxy (including two-component) and polyurethane. Any user can choose a grout depending on the conditions in which he has to lay the finishing material.

- Cement grouting mixtures are the most common due to their versatility, as they are suitable for outdoor interior work, and low prices.Such grouting is very good for processing different widths of joints: both narrow and wide.

- Epoxy grouts are ideal for use in bathrooms and swimming pools as they are highly resistant to moisture. Moreover, the line of epoxy mixtures has the greatest color variety, therefore they are ideal for almost any finishing material.

- Polyurethanee grout is the pride of the company. They are advanced and made from polyurethane resin. Such grouting mixtures are ideal for floor work, as they withstand high physical stress and are resistant to deformation.

The assortment of the company includes various decorative additives that allow you to experiment with decor and create a unique mix. Litokol offers its customers different forms of mixtures production: in plastic buckets and bags of different weight.

Colors

The color range of grout mixes is extremely diverse, especially among the epoxy type. In total, there are about 32 shades in the assortment, which is an impressive indicator among competitors.

Among the palette of two-component epoxy mixtures, there is even a transparent shade suitable for working with glass tiles. The most popular shade is wenge, which is suitable for working with porcelain stoneware and other finishing materials that have a natural color. Light beige grout is equally popular because it is used with many light-colored finishing materials.

Payment

As for the consumption of grout, many sites have a calculator that will allow you to very accurately calculate how much material is needed for each particular case. For those buyers who do not trust automatic calculators, the manufacturer offers an expense table.

Average consumption of Litokol grouting mixtures varies from 0.25 to 0.5 kg per 1 m2. The final amount of the product depends on the type of grout chosen, the width of the joints, the tile format and the area to be laid. The manufacturer indicates on the marking the width of the seams that each specific tool is designed to process. The numbers after the name of the grout indicate to the buyer the width of the joints.

Instructions for use

First of all, it is necessary to prepare a mortar of the mixture, since cement and epoxy grout are available in powder form. The polyurethane type does not require preparation for use.

It is important to note that when using a two-component mixture, stir it not by hand, but with a mechanical stirrer. It is in this case that the mixture will turn out to be of much better quality.

The next step is the preparation of the surface itself. It is necessary to remove the old coating, dirt and various residues of glue or cement screed. Do not neglect these procedures, since only on a clean surface the grout will hold the entire period declared by the manufacturer.

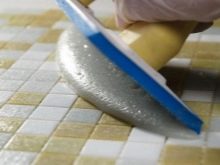

It's easy to figure out how to properly grind the tile joints. The best way to do this is to use a rubber trowel or plastering trowel. You should also start working from the far corner of the room. Seams are filled with a trowel at a 45 degree angle.

After the mixture has been applied to the tile joints, it is worth removing all grout stains within 45 minutes. This must be done in a timely manner, until the mixture has completely frozen. An ordinary sponge or a rubber spatula, pre-moistened with water, is perfect for this.

In most cases, walking on the treated tile surface can be started after 24 hours. But it is worth considering that this is also the composition of the grout, since different compositions dry in different ways. Full operation and hardening of the surface under the condition of exposure to any chemical compounds is allowed 5-7 days. The declared temperature regime should be maintained during this period, for example, for an epoxy mixture, this temperature is approximately plus 23 degrees.

How to store?

The shelf life of Litokol grouts is determined by the type of mixture itself. Usually the shelf life of the cement mixture is 12 months, and the shelf life of epoxy and polyurethane is 24 months. The mixture is stored at an average temperature of + 10 ... +30 degrees. But this can also vary depending on the type of mixture.

However, polyurethane grout has a big plus, since after its application, the remaining material can be reused. It should be stored at a temperature of + 5 ... +30 degrees. Under these conditions, this mixture can be reused without problems after a few months.

Buyers' opinion on quality

Customer reviews of Litokol grout are very positive. Many consumers like the wide range of colors offered by the manufacturer, which allows them to match the color of the grout mixture to any tile. The result is also pleasing, the seams are neat, strong, and all types of grout do not turn yellow and do not turn black over time.

However, many do not recommend using epoxy grout when doing independent work, as it is difficult to apply. Nevertheless, many consumers leave feedback on the successful work with this product, even with the initial experience. Also, users of these products note that Litokol grout is one of the best in its price category.

Useful Tips

Before starting work, it is worth making sure that the room temperature is within the acceptable range. For example, for some Litokol epoxy mixtures this norm is + 16… -25 degrees. This is due to the fact that at low temperatures the composition begins to solidify, becomes too viscous and difficult, inconvenient to work with.

If, when working with the grout mixture, there are stubborn stains and plaque left, then you can use the special Litostrip gel.

Also, for more comfortable work, the manufacturer recommends purchasing additional tools:

- a combined cellulose sponge that forms seams faster;

- skipper - a special bucket equipped with rollers for wringing;

- a grater with a replaceable cellulose nozzle used to clean up residues.

When you have a complete understanding of the tile grout from Litokol, it will not be difficult to make the right choice. In order for the material to show its best side, it is enough to use the recommendations given above.

For the properties of the Litokol grouting mixture, see the following video.

The comment was sent successfully.