Portland cement: technical characteristics and application

Currently, Portland cement is rightfully recognized as the most common type of binder for concrete solutions. It is made from carbonate rocks. It is often used in concrete production. Today we will take a closer look at what technical characteristics are inherent in this material, as well as how it can be applied.

What it is?

Before considering the characteristics and features of a material such as Portland cement, it is worth figuring out what it is.

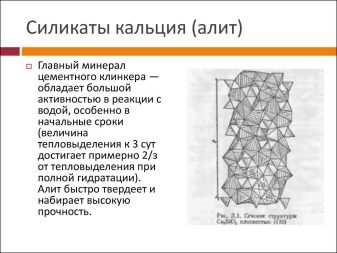

Portland cement is a type of cement, which is a special hydraulic and binding agent. To a greater extent, it consists of calcium silicate. This component takes up approximately 70-80% of the percent of such a cement composition.

This type of cement slurry is popular all over the world. It got its name from the island, which is located on the coast of Great Britain, as the rocks from Portland have exactly the same color.

Advantages and disadvantages

Portland cement has strengths and weaknesses.

To begin with, it is worth considering what advantages this material has:

- It should be noted the excellent strength characteristics of Portland cement. That is why it is most often used in the manufacture of monolithic reinforced concrete structures and other similar objects.

- Portland cement is frost resistant. He is not afraid of low temperatures. In such conditions, the material does not undergo deformation and does not crack.

- This material is waterproof. It does not suffer from contact with dampness and moisture.

- Portland cement can be used even for foundation construction in difficult ground conditions. For such conditions, a sulfate-resistant solution is used.

- There are several varieties of Portland cement - each buyer can choose the best option for himself. You can purchase a quick-hardening or medium-hardening compound.

- If you purchased a really high-quality Portland cement, then you do not have to worry about its subsequent shrinkage and deformation. After installation, it does not form cracks or other similar damage.

There are not many disadvantages of Portland cement. As a rule, they are associated with low-quality solutions, of which there are a lot in stores today.

Among them are the following:

- During its complete hardening, a low-quality material is susceptible to deformation. This must be taken into account when working. All shrinkage joints should also be provided.

- This solution cannot be called environmentally friendly, since in its composition, in addition to natural ones, there are many chemical components.

- Care should be taken when handling Portland cement, as contact with it can cause chemical burns and irritation. According to experts, in conditions of long-term contact with this material, it is possible to earn lung cancer.

Unfortunately, today many buyers are faced with low-quality Portland cement mortars. This product must comply with GOST 10178-75. Otherwise, the mixture may not be as strong and reliable.

Features of production

The composition of modern Portland cement contains lime, gypsum and special clinker clay that has undergone special processing.

Also, this type of cement is supplemented with corrective components that improve the technical characteristics of the mortar:

- provide him with the proper density;

- determine one or another speed of solidification;

- make the material resistant to external and technogenic factors.

The production of this type of cement is based on calcium silicates. Plaster is used to adjust the setting. Portland cement is produced by firing (according to a special formula) a certain mixture with a large amount of calcium.

In the production of Portland cement, one cannot do without carbonate rocks. These include:

- chalk;

- limestone;

- silica;

- alumina.

Also, often in the manufacturing process, a component such as marl is often used. It is a combination of clay and carbonate rocks.

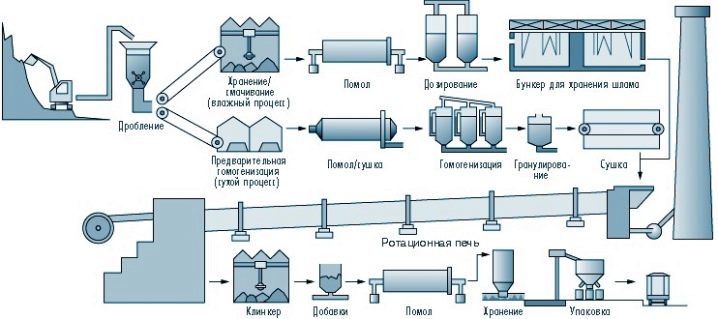

If we consider the process of manufacturing Portland cement in detail, then we can conclude that it consists in grinding the necessary raw materials. After that, it is properly mixed in certain proportions and fired in ovens. At the same time, the temperature regime remains at 1300-1400 degrees. Under such conditions, roasting and melting of raw materials is ensured. At this stage, a product called clinker is obtained.

To obtain the finished product, the cement composition is ground againand then mixed with gypsum. The resulting product must pass all checks to confirm its quality. The proven and reliable composition always has the appropriate certificates of the required sample.

To produce high-quality Portland cement as a result, several methods are used to create it:

- dry;

- semi-dry;

- combined;

- wet.

Dry and wet production methods are most commonly used.

Wet

This production option involves the creation of Portland cement with the addition of a special carbonate component (chalk) and a silicone element - clay.

Iron supplements are often used:

- pyrite cinders;

- converter sludge.

Care must be taken to ensure that the moisture content of the silicone component does not exceed 29% and that of the clay does not exceed 20%.

This method of making durable cement is called wet, since the grinding of all components occurs in water. At the same time, a charge is formed at the outlet, which is a suspension on a water basis. Typically, its moisture content ranges from 30% to 50%.

After that, the sludge is fired directly in the furnace. At this stage, carbon dioxide is released from it. The clinker balls that appear are carefully ground until they turn into a powder, which can already be called cement.

Semi-dry

For the semi-dry manufacturing method, components such as lime and clay are used. According to the standard scheme, these components are crushed and dried. Then they are mixed, crushed again and adjusted with a variety of additives.

At the end of all stages of production, clay and lime are granulated and fired. We can say that the semi-dry method of production is almost the same as the dry one. One of the differences between these methods is the size of the ground raw material.

Dry

The dry method of manufacturing Portland cement is rightfully recognized as the most economical. Its distinctive feature lies in the fact that at all stages of production, raw materials are used that are exclusively in a dry state.

One or another technology for the manufacture of cement directly depends on the physical and chemical properties of raw materials. The most popular is the production of the material under the conditions of special rotary kilns. In this case, components such as clay and lime should be used.

When the clay and lime are completely crushed in a special crushing apparatus, they are dried to the required state. In this case, the humidity level should not exceed 1%. As for directly grinding and drying, they are carried out in a special separator machine. Then the resulting mixture is transferred to cyclonic heat exchangers and remains there for a very short time - no more than 30 seconds.

This is followed by a stage during which the prepared raw material is directly fired. After that, it is transferred to the refrigerator. Then the clinker is “moved” to the warehouse, where it will be thoroughly ground and packed. In this case, the preliminary preparation of the gypsum component and all additional elements, as well as the future storage and transportation of clinker, will take place in the same way as with the wet production method.

Mixed

Otherwise, this production technology is called combined. With it, the sludge is obtained by the wet method, and after that the resulting mixture is freed from excess moisture using special filters. This process should continue until the humidity level is 16-18%. After that, the mixture is transferred to firing.

There is another option for mixed production of a cement mixture. In this case, dry preparation of raw materials is provided, which is then diluted with water (10-14%) and subjected to subsequent granulation. It is necessary that the size of the granules should not be more than 15 cm. Only after that they start firing the raw materials.

How is it different from simple cement?

Many consumers are wondering what is the difference between Portland cement and conventional cement.

It should be immediately noted that clinker cement is one of the subtypes of the classic mortar. As a rule, it is used in the production of concrete, which, in turn, is indispensable in the construction of monolithic and reinforced concrete structures.

First of all, the differences between the two solutions are in their appearance, performance and properties. So, Portland cement is more resistant to low temperatures, since it contains special additives. For simple cement, these characteristics are much weaker.

Portland cement has a lighter color than ordinary cement. Thanks to this characteristic, the dye is significantly saved during construction and finishing work.

Portland cement is more popular and in demand than conventional cement, despite its chemical composition. It is his experts who recommend using it in construction work, especially if they are large-scale.

Types and characteristics

There are several types of Portland cement.

- Quick drying. Such a composition is supplemented with minerals and slag components, therefore it completely hardens within the first three days. Thanks to this feature, the holding time of the monolith in the formwork is noticeably reduced. It is worth noting that in the process of drying quick-drying Portland cement, it increases its strength characteristics. Marking of quick-drying mixtures - M400, M500.

- Normally hardening. In the composition of such Portland cement, there are no additives that affect the hardening period of the solution. In addition, it does not need a fine grind. Such a composition must have characteristics that correspond to GOST 31108-2003.

- Plasticized. This Portland cement contains special additives called plasticizers. They provide cement with high mobility, increased strength properties, resistance to different temperature conditions and minimal moisture absorption.

- Hydrophobic. A similar Portland cement is obtained by introducing components such as asidol, mylonft and other hydrophobic additives.The main feature of hydrophobic Portland cement is a slight increase in setting time, as well as the ability not to absorb moisture into its structure.

Water from such solutions evaporates very slowly, so they are most often used in arid areas, where the stone must harden gradually so as not to lose strength.

- Sulfate resistant. The sulfate-resistant type of Portland cement is used to obtain high-quality concrete that is not afraid of low temperatures and frost. This material can be used in the construction of buildings and structures that are affected by sulfate waters. Such cement prevents the formation of corrosion on structures. Grades of sulfate-resistant Portland cement - 300, 400, 500.

- Acid resistant. The content of this Portland cement contains quartz sand and sodium silicofluoride. These components are not afraid of contact with aggressive chemicals.

- Aluminous. Alumina clinker cement is characterized by a composition in which alumina is present in high concentration. Thanks to this component, this composition has a minimum setting and drying time.

- Pozzolanic. Pozzolanic cement is rich in mineral additives (volcanic and sedimentary origin). These components make up about 40% of the total composition. Mineral additives in pozzolanic Portland cement provide higher waterproof performance. However, they do not contribute to the formation of efflorescence on the surface of an already dried solution.

- White. Such solutions are made from pure lime and white clay. To achieve a greater whitening effect, the clinker goes through a process of additional cooling with water. White Portland cement is most often used in finishing and architectural work, as well as colored. It can also act as the basis for a colored Portland cement mortar. The marking of this composition is M400, M500.

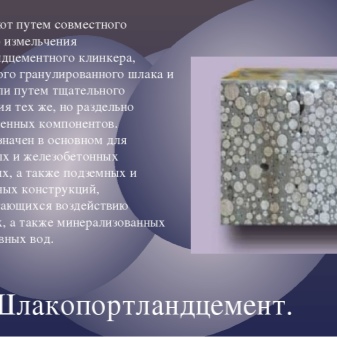

- Slag Portland cement. This type of Portland cement is used for the manufacture of heat-resistant concrete. Such a material has a low coefficient of frost resistance, which is why it is so often used in the construction of not only ground, but also underground and underwater structures.

A characteristic feature of Portland slag cement is that it contains a high content of the smallest metal particles due to the addition of blast furnace slags.

- Backfill. Special oil-well Portland cement is most often used for cementing gas and oil wells. The composition of this cement is mineralogical. It is diluted with quartz sand or limestone slag.

There are several varieties of this cement:

- sandy;

- weighted;

- low hygroscopic;

- salt-resistant.

- Slag alkaline. Such Portland cement has additives from alkali, as well as ground slag. There are compositions in which clay components are present. Slag-alkaline cement grabs in the same way as ordinary Portland cement with a sandy base, however, it is characterized by increased resistance to negative external factors and low temperatures. Also, such a solution has a low level of moisture absorption.

As you can see, the technical and physical properties of different types of Portland cement are very different from each other. Thanks to such a wide choice, you can choose a solution for both construction and finishing work in any conditions.

Marking

All varieties of Portland cement differ in their markings:

- M700 is a very durable compound. It is he who is used in the manufacture of high-strength concrete for the construction of complex and large structures. Such a mixture is not cheap, therefore it is extremely rarely used for the construction of small structures.

- М600 is a composition of increased strength, which is most often used in the production of critical reinforced concrete elements and complex structures.

- M500 is also highly durable. Thanks to this quality, it can be used in the reconstruction of various buildings that have suffered serious accidents and destruction. Also, the composition M500 is used for laying road surfaces.

- M400 is the most affordable and widespread. It has good frost resistance and moisture resistance parameters. Clinker M400 can be used for the construction of structures for any purpose.

Scope of application

As mentioned above, Portland cement is an improved type of cementitious mortar. Certain technical characteristics inherent in this material directly depend on the direct type of filler. So, quick-drying Portland cement marked 500 and 600 boasts fast hardening, therefore it is mixed into concrete for the construction of massive and large-sized structures, and they can be both above-ground and underground. In addition, this composition is often referred to in cases where the fastest possible set of strength is required. Most often, this need arises when pouring the foundation.

Portland cement with the 400 marking is rightfully recognized as more common. It is versatile in its application. It is used to create powerful monolithic and reinforced concrete parts, which are subject to increased strength requirements. This composition is slightly behind the 500 grade Portland cement, but it is cheaper.

Sulfate-resistant binder is often used to prepare mixtures involved in the construction of various structures under water. This advanced Portland cement is indispensable in these conditions, as underwater structures are particularly susceptible to the harmful effects of sulphate waters.

Cement with a plasticizer and marking 300-600 increases the plasticity properties of the mortar, and also increases its strength characteristics. Using such Portland cement, you can save about 5-8% of the binder, especially when compared to plain cement.

Special varieties of Portland cement are not often used for small-scale construction work. This is due to their high cost. And not every consumer is well familiar with such compositions. Still, Portland cement, as a rule, is used in the construction of large and important facilities.

When should not be used?

Portland cement endows ordinary concrete with special properties and strength properties, which makes it very popular in construction work (especially large-scale). However, such a solution cannot be used in flowing river beds, salt water bodies, as well as in water with a high content of mineral substances.

Even a sulfate-resistant type of cement will not cope with its main functions in such conditions, since it is designed for operation in static and temperate waters.

Usage Tips

Portland cement is more complex in composition than conventional mortar.

When working with such materials, you should heed the advice and recommendations of experts:

- In order for the solution to harden as soon as possible, it is necessary to select a suitable mineralogical composition of the cement, as well as apply special additives. Often in such cases, they turn to electrical heating or heat-damp processing.

- Sodium, potassium and ammonium nitrates are used to slow down the hardening. NS

- It is necessary to take into account the setting time of the cement paste. The beginning of this process occurs not earlier than after 30-40 minutes, and the completion - not later than after 8 hours.

- If Portland cement is planned to be used for arranging the foundation in complex soil conditions, then experts strongly recommend choosing a sulfate-resistant solution, which has a high content of mineral components.

- Colored or white Portland cement is ideal for flooring.Using such a solution, you can create beautiful mosaic, tiled and brecciated coatings.

- Portland cement is not uncommon. You can buy it at almost any hardware store. It must be properly prepared for work. To do this, you need to take 1.4-2.1 water for every 10 kg of cement. To calculate the exact amount of liquid required, you need to pay attention to the degree of density of the solution.

- Pay attention to the composition of Portland cement. If it contains various additives to improve moisture-resistant qualities, then frost-resistant characteristics will decrease. If you are choosing cement for a humid climate, then a regular mortar will not work for you. It is better to purchase slag portland cement.

- Colored and white clinker mixtures must be transported and stored in a special container.

- There are a lot of fake clinker compounds in stores today. Experts strongly recommend that you familiarize yourself with the quality certificates of goods when buying, otherwise the cement may turn out to be of low quality.

The process of obtaining Portland cement can be viewed below.

The comment was sent successfully.