Consumption of concrete contact per 1 m2: norms for different surfaces

Initially, the builders needed a compound to improve adhesion to concrete, hence the name, but the resulting formula made it possible to significantly expand the scope of the new product. Tiles, old enamel paint, drywall, polished steel required either complete dismantling, or careful sanding and notching. With the advent of concrete contact, this situation has changed.

The universal primer provides excellent adhesion to any type of substrate and topcoat. The durability of the fastening today is about 80 years.

Features and composition

The basis of concrete contact is acrylic (latex) and glue, adhesion, roughness are provided by cement mixtures, gypsum, quartz sand or marble chips. The size of fractions for putty - 0.3, for plaster - up to 0.6 mm. Numerous polymer additives, additives increase the quality of the material. And they also expand its properties for use in different operating conditions: dry climates, with excess moisture levels, for floors, walls, etc.

Organic solvents are used as a diluent for preparing the solution. It is difficult to achieve a homogeneous composition when mixing acrylic mixtures with water, so it can be used only if the manufacturer recommends.

Penetration rate in the range:

- for a universal mixture - 5 cm;

- deep penetration - 10 cm.

The drying time of the concrete contact is from 2 to 24 hours based on the climatic characteristics and the possibility of airing the room.

Advantages:

- Versatility. Suitable for all types of surfaces, does not require careful preparation before application. Insensitive to stubborn oil and other greasy stains. However, the use of such a primer is justified only in cases of smooth and almost non-absorbent surfaces.

- Strength. The finished primer does not crack during drilling or other construction work.

- Reduces the ability of a base with a porous surface to absorb moisture: brick, gypsum, wood, aerated concrete.

- Water vapor permeability. Acrylic provides the effect of "breathing" walls.

- Resistant to moisture. Biocidal additives also prevent the penetration of bacteria or mold into the material, even after a while, it remains harmless to the cladding and human health.

- Immunity to low and high temperatures, their differences. This quality appears only after the soil has dried, the application itself is not lower than t +5 ºС.

- Does not contain flammable substances.

- Does not change properties under the influence of ultraviolet radiation.

- Environmental Safety. The glue does not contain toxic substances, which allows using the composition not only for external, but also for internal work. No special protective agents are required during application.

Disadvantages:

- Afraid of dust. Immediately before applying the concrete contact, the surface must be dedusted without fail.

- During work, the ready-made liquid mixture must be constantly mixed: heavy components settle to the bottom of the container.

The use of such a primer is justified in cases of smooth and almost non-absorbent surfaces. The maximum shelf life is from 6 months to a year. An accurate calculation of coverage is required for different types of base.

What determines the expense

The amount of mixture required to apply to different surfaces will vary.It all depends on the properties and structure of the walls or floor, primarily on the hygroscopicity, or, in other words, the ability to absorb water.

Minimum consumption of concrete contact per 1 m2:

- For brick, smooth concrete (polished) and sand concrete, which are porous surfaces, the recommended consumption is from 0.3 to 0.5 kg.

- For monolith, high-quality concrete, tiles made of it, self-leveling cement floors and finishing bricks and other bases with an average porosity - from 0.2 to 0.35 kg.

- Iron concrete smoothed with a trowel, tiles, old enamel paint and others corresponding to low-porous and smooth materials - from 0.15 to 0.25 kg.

The best method to find out the rate of consumption for the desired surface is to use a 1 x 1 meter square probe. Select part of the solution and what you will be applying the primer with. Weigh the mixture with container and tool. Then apply the solution. Check how tightly it holds, if necessary, touch up. Then weigh the probe with the instrument again. The difference between the first value and the second is the flow rate that is needed.

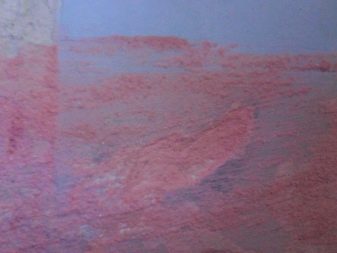

High-quality pouring of the mixture is distinguished by the fact that everything looks smooth, there are no gaps, the grip is even. If there are gaps or the adhesion of the solution is not enough: sand or cement crumbles on contact, then another additional layer is needed for reliability. The second application always requires 20-30% less solution.

Saving the mixture

You cannot reduce material consumption. Manufacturers warn that the liquid solution can lead to a decrease in adhesion, that is, the concrete contact will not be able to adhere to smooth surfaces. In addition, in the process of work, the uniformity of drying is disturbed. Water evaporates or absorbs into the substrate too quickly, preventing a good bond. As a result, heavy fractions simply crumble.

Minimal losses - the formation of cracks, which will still entail a complete rework, and hence the waste of money in double the amount. The watery composition also reduces the waterproofing properties of the future surface.

Recommendations

- When buying, always choose a product that specialists and ordinary buyers who have done repairs at home speak positively about. Cunning and cunning sellers can sell expired material or even a fake, you need to protect yourself from such a mistake.

- If you are not sure that this particular soil is suitable for the surface, use probes to check or check with the store's consultant for information. He will tell you which company is better to prefer, how to use it, for which surface it is suitable.

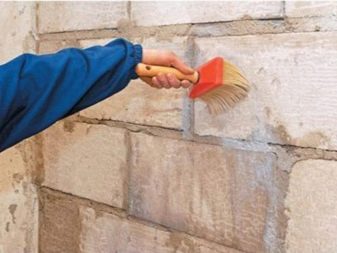

- Before you start work, do not forget to get rid of the required space of excessive dust, large, small debris, and dirt. Use a vacuum cleaner for large debris (if it is the floor).

If there are irregularities or crumbling areas, they must be cleaned in any convenient way. It is better to dry the surface in advance.

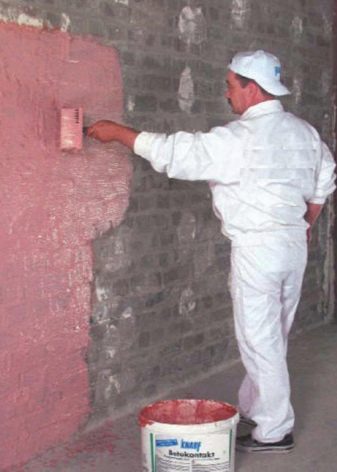

- To work with a concrete contact, you can work with whatever is more convenient for you. A roller or brush is good for small areas, a spray gun for large areas. But it should be provided that the nozzle corresponds to the size of the fractions of the solution.

- Be sure to wait until everything is soaked and dry, and only then apply another layer or a fine finish in the form of a tile, for example.

- It is better to apply the finishing option immediately after the primer is dry. If this is neglected, then a sufficient amount of dust can accumulate, which subsequently will only lead to a decrease in strength. Therefore, cover the work area with protective material.

- Keep the rest of the primer in a positive temperature. If the concrete contact freezes, it will lose all its properties and its further use is useless.

- Try to purchase concrete contact from well-known and proven brands that do not seek to deceive, but value their reputation.

Top manufacturers

There are many different manufacturers of concrete contact on the market now.The cost usually ranges between 300-600 rubles for five kilograms. If you wish, you can find more expensive, but not the fact that it is of better quality. The scope, consumption of the mixture or ready-made solution is indicated on the package.

KNAUF

It manufactures products for the treatment of any surfaces, the solution is intended for both manual and mechanized work. Consumption approx. 0.35 kg / m2. Color - pink to control the uniformity of the application. Curing time - 12 hours. Price 20 kg - 3330 rubles.

Acrylic based primer Beton Kontakt - Recommended before laying tile or porcelain stoneware tiles, applying finishing decorative plaster, putty, with further pouring the floor.

Rotband-grund - is produced as a mixture, without solvents, modified dispersion. It is intended for processing porous substrates with increased moisture absorption, as well as in preparation for subsequent leveling with other types of plasters.

"Prospectors"

The primer contains BASF latex. Suitable for interior work, including crumbling walls with old plaster. Available in different sizes: 3, 8 or 16 kg buckets. Consists of copolymer acrylic dispersion, sand, water and various useful additives.

Used for walls, ceilings in rooms with normal or high humidity. 5 kg - 315; 8 kg - 725; 16 kg - 1350 rubles. Temperature limits during work - from +5 to + 30 ° С. Short shelf life - no more than 6 months from the date of issue.

There are ready-made solutions for deep penetration - up to 10 cm in a 20 kg package, which is enough for 67 m2 of base. These are quick-drying mortars that allow further finishing work within 2 hours. Minimum consumption - 0.2 kg / m2. The operating mode is in the range from +5 to + 25 ° С. Expiration date - 12 months.

Ceresit

Produces material for application on smooth surfaces, suitable for external and internal use. Consumption 0.3-04 kg / m2. Dries about three hours, pink. 5 kg - 465; 15 kg - 1265 rubles.

- CT 19. Provides surface frost resistance during operation. Allowed 5 freezing cycles for up to two weeks at a temperature not lower than -40 ° C. Conditions for carrying out finishing activities at an air and base temperature from +5 to + 30 ° C, air humidity should not exceed 80%. The adhesion of the mortar to the concrete base after a week is not less than 0.5 MPa.

- CT 17. Deep penetrating primer containing antiseptic.

"Phoenix" concrete contact

A primer on quartz sand creates a uniform rough layer. The mixture has a strong sticky property. Suitable for interior renovations with different types of surfaces. Consumption 0.2-0.3kg / m2. Do not freeze under any circumstances, store in a tightly closed container. Packing of 20 kg - 1200 rubles, enough for 67-100 m2. Temperature range of application is from +5 to + 40 ° С.

VGT

The company produces a coarse dispersion primer for treating poorly absorbent plaster substrates. Often used before laying ceramic tiles. Full hardening time is about 24 hours. Consumption - 0.25-0.5kg / m2. Price for 3 kg - 315; 8 kg - 725 rubles.

How to use concrete contact, tells the specialist in the following video.

The comment was sent successfully.