Dry mixes: types and features

For many centuries, mortars have been prepared directly at the sites where they were worked. But this creates a number of inconveniences and problems, since it is very difficult to maintain the exact proportions and observe the mixing technology.

After all, the conditions at a real construction site are quite far from standard, no matter how hard everyone working to maintain cleanliness and order.

Peculiarities

Some home craftsmen and even amateur builders are wondering why dry mixes are needed at all, if you can make a familiar solution yourself.

Compared to home-made mortars, industrial-made dry mix has a number of important advantages:

there is no need to independently dose all components and spend time on this;

the proportions are initially correct and comply with the standards;

you can limit yourself to adding water and thorough mixing.

But even these three circumstances do not exhaust the merits of the dry mix. Often a situation arises when tens or even hundreds of kilograms of mortar are required to pour the floor screed. It is quite easy to buy cement, lime and so on, but it is extremely difficult to buy the required amount of high-quality sand. In most cases, procurers trade in much larger quantities of it, and independent production is economically unprofitable. For repairs in an apartment or other room on the second and subsequent floors, a traditional cement and sand screed is quite heavy. If you prepare a solution from dry mixes, you can reduce the load on the floor.

It will be possible to put a heavier finishing material on top or reduce the requirements for the strength of the foundation. And the reduction of weights that will have to be lifted to the floor and transported around the house will only be a plus. There is no special need to use concrete mixers and mixers; you can prepare a solution from an anhydrous combination for casting floors in a large plastic container using attachments for electric drills. At the same time, 0.5 cm of dry screed in terms of hardness and portable power load is identical to 3 cm of the classic version made of cement and sand. Special additives reduce the drying time of the coating and ensure self-leveling of the screeds without the need for additional work on them. Manufacturers have established the production of mixes adapted for dry and wet rooms for rough and final finishing.

Types and technical characteristics

Despite the wide range of dry mortars currently available, they all belong to one of two basic categories - the cement or gypsum group. The first group is based on fine cement, but this does not mean that all of it is also homogeneous. So, when the mixture is prepared for the subfloor, expanded clay or granite chips are used as a filler. Such substances help to make the floor 3-4 cm thicker.

But the rough composition is not suitable for laying most of the front materials, and therefore more layers of finishing mixtures are made on top of them.

For the preparation of the final parts of the screed, a combination of finely dispersed cement with carefully selected plasticizers is used. The main purpose of using such mixtures is the formation of a very smooth and extremely even base, on which it will be easy to lay even a laminate or linoleum.With a carefully selected recipe and strict adherence to the technology in production, a layer of only 1 cm is enough for the final leveling.

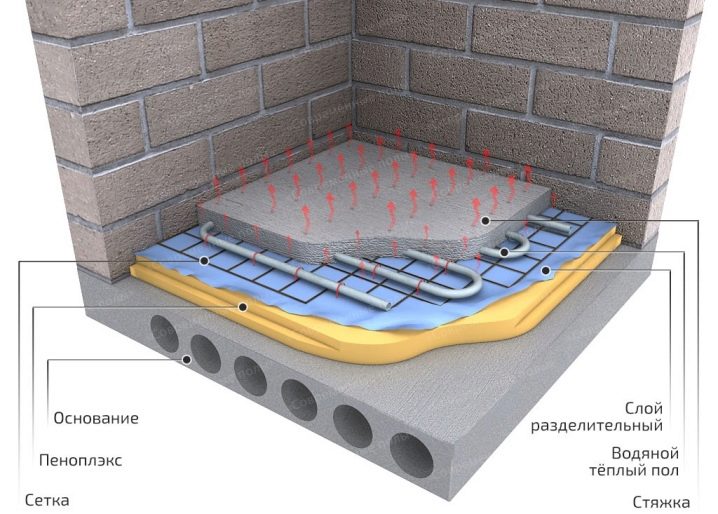

To obtain a self-leveling composition, especially small fractions of fillers are used - a particle diameter of a maximum of 0.03 cm.And even this is not enough, you will need to use special components that will make the screed level. When performing repair work, a screed is often made under a warm floor, this task imposes special requirements on the material.

It should be:

plastic;

well permeable to heat;

withstanding a solid load.

Gypsum mix, unlike concrete, dries quickly and costs less. At the same time, the level of thermal insulation and noise containment is quite satisfactory to the requirements of consumers. For the preparation of a gypsum solution, filling substances with a small diameter and various threads of mineral origin are taken, which significantly increase the strength of the structure. There can be only one problem: a gypsum-based mixture cannot be considered waterproof. It is categorically unacceptable to use it in rooms where the humidity level is above average.

A dry screed is applied to both wood and concrete. There is no need for wet work and no need to even wait until the floor is ready for use. For comparison: a typical sand screed or wet mix will dry 25 days, gypsum-based combinations will dry within 15 days. Before the end of this time, it is unacceptable to mount the front cover, it will simply block the exit of water to the outside and lead to unpleasant consequences.

A mortar mixture intended for outdoor use must necessarily contain substances that increase resistance to cold. If available, their coating will not only calmly endure the harsh winter, but can also be applied even in the cold season. In most mixtures, one or another saline solution is used for this purpose.

As for the general classification, builders and sellers distinguish the following types of dry mix according to the type of possible work:

putty;

plaster;

outdoor;

protective (stopping the negative effect of the weather);

assembly room;

masonry;

decorative;

primer;

waterproofing.

In addition to cement and gypsum, a number of polymers, lime and even more complex combinations can be used as a binder. Their variety makes it possible to provide such ambiguous and even contradictory properties.

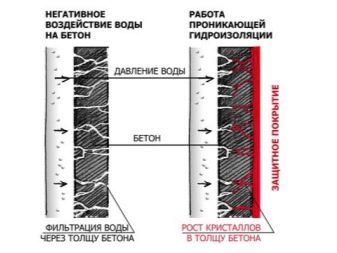

Dry mixes for waterproofing help to build underground and buried structures, preventing the negative effects of moisture on their basic materials. The penetrating variety of this material contains a cement base, aggregate and various additives. The porous structure of the material allows the additives to contact very easily with the main components throughout the entire thickness of the coating. The result is a durable and hydrophobic layer.

A capillary dry mixture is needed for waterproofing horizontal surfaces. The period of its service is practically unlimited, it is comparable to the time of operation of the most protected wall. Injectable formulations help to eliminate those defects that have already appeared. Mix M200 is intended for creating masonry and allows you to repair concrete walls, process the seams of building blocks. It can also be used for laying paving slabs, for preparing plaster. The chemical basis of the material is Portland cement and washed river sand.

A mixture on a lime-cement basis in its practical characteristics is far superior to a gypsum analogue, it is resistant to fungal infection and cracks little, it is well applied to wood. Builders appreciate this material due to its ductility and long drying time.

The cement mixture for the initial leveling is filled with expanded clay crushed stone, coarse sand or granite chips.Such combinations make it possible to create a constricting layer above the heating equipment, but expanded clay mixture is an exception to this rule. To lay linoleum or carpet, you will need to put a finishing layer on top, the tiles can be placed directly on the rough mass. In courtyards and stairwells, such screeds can be an independent coating.

Consumption

The solution consumption per 1 m3 depends on what proportions are ideal for a particular type of mixture. At the same time, it does not matter whether the composition is used to pour the floor screed or to create a full-fledged concrete block. Important: the amount of cement does not matter either, it will not affect the volume. Cement particles are extremely small and enter the gaps separating one grain of sand from another.

To obtain a mortar of category M200 using a binder grade M500, you need to add 25% cement and 75% sand. 1 cubic meter m of sand has a mass of 1.4 tons, which means the amount of cement will be 350 kg. The total mass reaches 1.75 tons.

But this is an average figure and, moreover, without taking into account the addition of water.

The weight of the mixture is determined by the proportion between sand and cement., as well as the filler fraction (the larger its particles, the heavier the building mixture). Of course, the thicker the layer you create, the more bags of building materials you will need to use. The calculation is relatively straightforward when the mass is known, you only need to divide it by 50 kg (the standard value of the bag capacity). The consumption of dry mixes for sealing joints is determined in accordance with the instructions of the manufacturers, each composition is strictly individual in its characteristics.

Manufacturers

Plants for the production of building materials have responded to the demand from professionals and amateur builders predictably and brought to the market many options for dry mixes. But in order to avoid problems, it is necessary to buy only high-quality formulations produced by leading manufacturers.

Knauf brand has an impeccable reputation. The product range of the German concern includes gypsum and cement products, some of the options contain expanded polystyrene granules. With the help of German mixtures, extremely thin substrates can be poured, the thickness of which ranges from 0.2 to 1.5 cm.

Another famous brand - Ceresit, is also famous all over the world and is presented in many options.

The leading Russian manufacturer is "Osnovit", which makes two types of mixes for rough work at once. One of these types is needed to prepare warm floors, while the other can become the basis for a thin floor.

Mixes Volma externally varied, but they are all designed for interior work in bathrooms and for cladding facades.

By varying the composition of the mixture, technologists can give it certain qualities that allow:

finish the building inside or outside;

prepare the surface for finishing;

strengthen the walls;

provide a normal microclimate in the house.

All brand products Volma are made on the basis of plaster and dry within 7 days. Thanks to specially selected additives, they are very durable and adhere to the surface thoroughly.

The color is most often white, light gray or gray.

Company products "Hercules" produced in Siberia and fully takes into account all the details of the Russian climate. It will help build a screed, repair and grind all kinds of seams, eliminate deformations and potholes. In the production process, modern dosing equipment, carefully selected materials and technological methods worked out over the years are used. The company has launched the production of plasters, plaster-based and polymer-based putties, masonry and cement mortars, alabaster, waterproofing and repair mixtures. Any of these materials perfectly withstands the action of water, mechanical stress and is quite elastic.

Under the brand "Stone Flower" M200 dry-type assembly and masonry mixes are produced. This composition is formed by Portland cement and dry sand.

The purpose of its application:

laying bricks;

sealing of seams and elimination of problems with them;

concrete pouring of stairs;

fixing the floor.

The used mixture easily tolerates cold, water exposure, and other unfavorable factors. The developers have managed to achieve high efficiency and ductility. The optimum temperature range during operation is from +5 to +30 degrees. Excellent adhesion is ensured to cement-lime, cement-sand substrates, concrete and bricks of all types.

Application and method of painting

It is necessary to prepare a dry building mixture and bring it into working mode strictly according to the very recipe that was developed by the manufacturer. For work, you will need water heated to 70-80 degrees, the amount of liquid must be determined individually. Mixing requires the use of a cyclic or continuous apparatus. It is necessary to clearly separate solutions into light and heavy groups. The film composition is designed to protect the main structure from the effects of water on the surface, penetrating works in its entire volume.

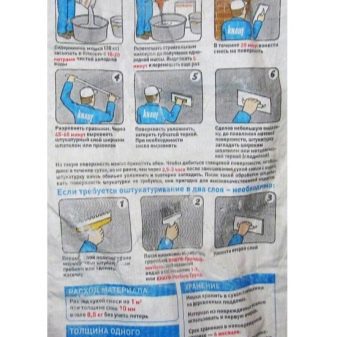

Manual mixing of the dry mixture is quite possible, but using a special mixer is much more correct., it saves both time and effort. That is why professional builders always use just such equipment, which allows them to perform work quickly. At home, it is worth buying an electric drill with a stirrer (a special nozzle in the form of a whisk). The instrument must be taken after checking so that it is perfectly clean.

When working, pour water and only then pour the dry mixture into the container.

After waiting for the dust to settle, they begin to mix the composition at medium speed. It is very important to hold the drill or mixer firmly so that the tool does not pull out of your hands. In the process of mixing, it is allowed to add both water and new portions of the mixture, which makes it possible to vary its density and plastic qualities.

For dry mixtures, water-based dye compositions are usually applied using rollers with long pile. To process corners and joints, you need to use paint brushes. You can adjust the color with a narrow brush. Painting work begins from the corner, and on the ceiling - from the junction with the wall, which falls on the corner farthest from the entrance.

Any water-based paint is applied in three layers:

parallel to the light from the window;

at right angles to it;

towards the window.

Advice

Dry building products are often used for floors, as this is one of the simplest ways to level and strengthen a structure. Best of all, cement-based mixtures show themselves, gypsum is somewhat worse. Only for solving a narrow range of problems is it advisable to use fine quartz sand and limestone. To create a rough screed on a very uneven base, coarse fractions are needed. If the relief defects are relatively small, it is advisable to use a mixture with particles up to 0.5 mm.

It is advisable to level the wooden floor with a compound with the inclusion of synthetic fiberglass. Before buying, it is advisable to find out the exact date of production, since even the best paper packaging with a polyethylene layer inside cannot protect the contents from getting wet. It is advisable not to buy funds produced more than 3 months ago, they are almost guaranteed to turn out to be worse than those shipped recently. Cement leveling agents are recommended for heavily deformed surfaces and for making a rough leveling layer.

Gypsum is unacceptable for work in rooms where there is a high concentration of water, as well as where the floor surface is under significant stress. Filling large areas of the floor requires the use of professional hand tools. Finishing in such areas is done in sections, which are separated by seams no higher than 1 cm.At least two people need to start work, because ready-made solutions dry quickly.

Before laying the sub-layer, the base must be free of dust and dirt.

The room should be cleared of furniture and foreign objects. After cleaning the base with a construction vacuum cleaner, it must be primed. When the substrate absorbs the primer intensively, two overlapping coats are required. It is categorically unacceptable to introduce an excessive amount of water and add foreign substances to the dry mixture that are not provided for in the manufacturer's instructions.

Leveling compounds should be used at an air humidity of no more than 85-90% at temperatures from +5 to + 25 degrees. You should never use more dry mixes per 1 sq. m of floor than indicated by the manufacturer. A gross mistake will also be the use of a finishing material for finishing and correcting defects in the rough base. When the coating dries, unwanted voids may appear in the cement layer.

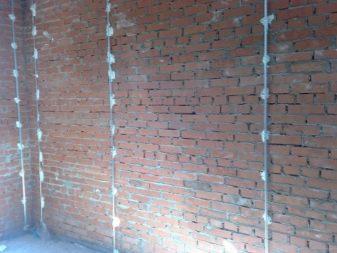

Plaster beacons, which are made of galvanized slats and are fixed strictly according to the indications of the building level, help to simplify the alignment of the wall in a house or apartment. To level the mixture applied to the wall, it is required to use the metal rule.

There is another technique: a reinforcing plastic mesh is glued to the walls, this will also facilitate the formation of the layer.

For the correct choice of dry mix, you need to take into account three main circumstances:

conditions for the performance of work;

the degree of curvature and surface relief;

the cost of a specific product (which is also influenced by the brand).

The higher the cement grade number, the stronger the mix will be. But walls in a house or apartment can be covered with relatively weak cements of the M150 category. On a concrete surface that is not covered with a reinforcing mesh, no more than 2 cm of the mixture can be applied, and if the wall is made of brick, this figure is a maximum of 2.5 cm.

Careful selection of dry mix is extremely important to meet the challenges. If you follow all the rules for its application and preparation, you can guarantee the elimination of critical moments. But in case of the slightest doubt and in the absence of self-confidence, it is more correct to turn to specialists.

For information on how to distinguish the original dry mix from a fake, see the next video.

The comment was sent successfully.