Mixture for laying brick ovens: selection and use

It is difficult to imagine a private house without a traditional brick stove or a modern fireplace. These indispensable attributes not only provide warmth to the room, but also serve as a decoration for a fashionable interior. To create a solid monolithic brick structure, special mixtures are used that have fire resistance, ductility and very high strength.

Appointment

When constructing a brick stove or fireplace, special compounds are used, to which special requirements are imposed. Heating structures are used in "extreme" situations where temperatures change to very high rates. The duration of this exposure can be several hours, therefore the material must be adapted to such exposure.

With this operation of the structure, special attention should be paid to the composition of the mixture. It should not contain toxic components that could be released into the environment. Also important is the absence of any specific odors. These products must comply with sanitary standards.

The special composition of the mixture allows filling the openings between the seams, which is a reliable barrier to the penetration of carbon monoxide into the heated space. Due to the absence of cracks, air diffusion does not occur and the draft is not disturbed.

These solutions are used for the following work:

- brick laying of external surfaces;

- combustion chamber device;

- construction of chimneys, including the surface that goes out;

- pouring the foundation;

- facing;

- creation of additional elements exposed to high temperatures.

Depending on the purpose, the type and proportions of the composition are selected.

Formulation options

There are ready-made repair mortars that contain all the necessary components in the right proportion. Also, the composition can be prepared by hand.

Below are the varieties of solutions.

- Clay sand. The mixtures have medium heat resistance and high gas density; they are not used outdoors. To prepare them, special skills are required. They are used for laying the heat-storage part of the stove and the initial part of the chimney.

- Cement-clay. The solutions are highly durable. They are used for laying the heat-storing part of the stove and the base of the chimney.

- Cement. The mixtures have high strength and low gas density. Used for laying the foundation.

- Cement-lime. Solutions have a higher strength, but they are endowed with a low gas density. They are used for laying the foundation of a stove, fireplace, part of the chimney, which rests against the ceiling, the main and final parts of the chimney.

- Lime-clay. The mixtures are durable and have an average gas density. They are used for laying the heat-storage part of the stove and the base of the chimney.

- Fireclay. The solutions are endowed with high heat resistance and strength. They are used for laying the furnace part of a stove or fireplace.

- Calcareous. Indicators of heat resistance, fire resistance and gas density are below average. The formulations can be used outdoors. They are used for laying the foundation of the stove and fireplace.

In addition to the main components, the compositions may contain plasticizers, salt and other additives that increase the quality of the material, making it more plastic, durable, heat-resistant, airtight, and impervious to high-temperature environments.The purpose of the composition is determined by the quantitative content of a particular component.

Ready mixes for brick luggage are divided into ordinary and improved options. Their difference lies in the operating conditions of the heating structure. The improved formula contains additional components that allow it to withstand temperature extremes, as well as temperatures reaching 1300 degrees.

Below are the most common ready-made formulations.

- "Terracotta". The heat-resistant mixture is environmentally friendly, durable and flexible. The composition includes components such as kaolin clay, sand, chamotte. The maximum operating temperature of the material is 1300 degrees above zero. According to reviews on the Internet, the solution has high strength, reliability, plasticity, uniformity and ease of use. However, there are opinions that the mixture must be sieved, since large grains of sand come across in the composition. There are similar packages with the composition, which may differ slightly, for example, more clay is present. It is also noted that it is difficult to work with dry bricks and it is better to use soaked bricks.

- "Pechnik". A heat-resistant mixture based on cement and clay is characterized by fire resistance, strength and high water-holding properties. The maximum operating temperature of the material is 1350 degrees above zero. Among the reviews on the Internet, there are both positive and negative opinions. Of the advantages, high strength, reliability, heat resistance and ease of use are noted. Among the disadvantages, users notice a high consumption of material, fast solidification and high cost.

- "Emelya". A mixture based on kaolin clay contains additional components that increase the strength, adhesion and plasticity of the material. Also, the solution is characterized by heat resistance, moisture resistance and odorlessness. The permissible operating temperature of the material is no more than 900 degrees above zero. Among the positive judgments are heat resistance, low odor and ease of use. Among the negative reviews, the low strength of the material and the lack of moisture resistance are noted.

- "Vetonit". The clay-based mixture is heat-resistant and durable. The composition also contains cement, sand, additional additives that increase the quality of the solution. It is not used for laying ceramic bricks. Withstands temperatures up to 1200 degrees above zero. Among the positive reviews are good strength, ease of use and high quality products. Among the negative aspects, there is a slight flowability of the material after drying.

- Borovichi. The clay mixture contains quartz and molding sand. The solution is plastic and heat resistant. The composition is used for laying red bricks. The operating temperature of the material should not exceed 850 degrees. User reviews indicate that the solution is durable, strong and of high quality. Among the negative aspects, there is a lack of plasticity.

It should be noted that in order to obtain a high-quality solution, it is necessary to strictly follow the instructions for use. Any deviations can lead to undesirable results in the form of heterogeneity of the mixture and its rapid solidification. In order for the mixture to retain its strength properties for a long time, it must be used for its intended purpose.

Therefore, before using any composition, you must consult with a specialist.

- Clay. The natural element contains aluminum, silicon, sand and other components. The range of colors is very diverse. The main characteristic of clay is the fat content - it determines properties such as strength, gas density and adhesion.

- Cement. The mineral powder is characterized by high strength properties.The material is obtained from clinker by crushing it. Then minerals and gypsum are added. Kiln masonry often uses Portland cement, which is obtained by firing, a method that improves quality and performance.

- Lime. The building material is fired at high temperatures during the production process. Lime does not contain any chemical additives, therefore it is considered an environmentally friendly substance. It contains carbonates and minerals. When laying stoves or fireplaces, lime paste is used. A dense mass is obtained by slaking lime in water.

- Chamotte. Refractory material is obtained by deep firing. It contains components such as high-alumina clay, zirconium, garnet.

The quantitative content of one or another component significantly changes the properties of the solution, making it more viscous, for example, with a higher clay content, or strong with a higher cement or lime content. Fireclay materials significantly increase the heat-resistant performance of the mixture.

Preparation

Ready mixtures must be diluted with water in accordance with the proportion indicated in the instructions for use. Sometimes special solutions are used for this. This is the most convenient option, however, the cost of such compositions, in contrast to homemade mixtures, is much higher.

For cooking, you need a container and a mixer. First, prepare the required amount of liquid, and then gradually add the mixture. The amount of water is indicated on the package, but remember that in high humidity environments, the amount of water should be less than in hot weather. The liquid consistency is thoroughly mixed until a homogeneous slurry is formed. Then the solution is infused for an hour and stirred again.

To prepare the solution with your own hands, you will need to purchase all the necessary ingredients, then mix them in the right proportion. This method is much cheaper. The advantages include the ability to use environmentally friendly products. However, difficulties can arise with finding the right ingredients, as well as preparing the right proportion.

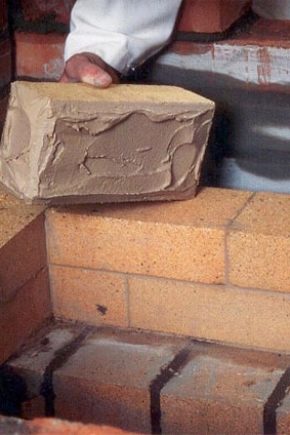

Stove masonry involves the use of different compounds depending on the type of surface. When forming a base that is underground, cement compositions are suitable. To form the side walls of the furnace, where the greatest exposure to high temperature occurs, a refractory clay mortar must be used. The mixture should be prepared every day, removing dust, dirt and foreign particles from the components.

The clay is soaked in advance. The material is kept in water for up to two days, during which the material is stirred. The amount of water is determined from a ratio of 1: 4, where one part of water fills four parts of clay.

To prepare a mortar from cement, you need cement powder, sand and water. The ratio of powder and sand is selected depending on where the composition will be used. The mixture is added to water, stirring thoroughly until a homogeneous mass is obtained. For stirring, use special devices, for example, a trowel or mixer. In some cases, crushed stone is added to increase strength.

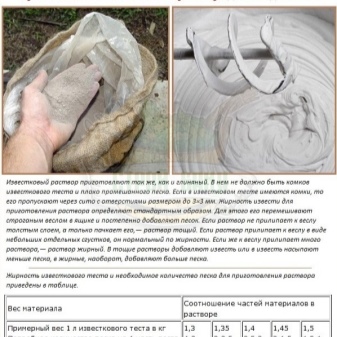

Clay-sand mixture is prepared by mixing clay with sand. The proportion is selected depending on the purpose, as well as the initial properties of the clay. Before mixing the components, the clay is thoroughly cleaned and sieved.

If the clay has an average fat content, then the approximate proportion can be 4: 2 - 4 liters of pure clay are poured into a previously prepared container, then 2 liters of sand. The components are mixed, then water is added in small portions, stirring the mixture thoroughly. The result should be a homogeneous gruel, similar in consistency to sour cream.

To prepare the lime mixture, you will need lime, sand and water. The proportion is chosen depending on the purpose of the solution.Before preparing the mixture, the lime is thoroughly cleaned and sieved. First, dry components are mixed, then water is gradually added, stirring the composition.

Cement-lime mortar is prepared from cement, lime, sand and water. The proportion is selected depending on the purpose of the mixture. The dry components are mixed. Then gradually add water, stirring the solution thoroughly.

Cement-gypsum mortar is prepared on the basis of lime, gypsum, sand and water. Before work, lime is cleaned and sieved. The ratio of the components is selected depending on the purpose of the solution. First mix the dry ingredients, then add water in small portions. In this case, the composition is thoroughly mixed, bringing it to the desired consistency.

Lime-clay solution is prepared on the basis of lime, clay, sand and water. Before work, it is necessary to carry out work on cleaning and sieving lime and clay. The ratio of dry components is selected depending on the purpose of the solution. First, the dry components are mixed, then the liquid is slowly added in small portions. In this case, the gruel is thoroughly stirred, bringing to a homogeneous mass.

Cement-clay mortar is prepared from cement, clay, sand and water. Before starting the preparation of the mixture, the clay is thoroughly cleaned and sieved. The approximate ratio of dry components is 1: 4: 12, where one part of cement is mixed with four parts of clay and twelve parts of sand. Then slowly add water in small portions, stirring thoroughly, and bring to the desired consistency.

To prepare fireclay masonry mortar with increased strength, you will need Portland cement M400, sand, crushed stone and fireclay sand. The approximate ratio is 1: 2: 2: 0.3, where one part of cement is mixed with two parts of ordinary sand, two parts of crushed stone and 0.3 part of chamotte sand. Then add water, stir slowly until a homogeneous consistency is obtained.

It should be noted that the process of making a mixture with your own hands is a rather laborious and responsible occupation. Poor quality material or the wrong proportion can lead to undesirable consequences, additional money and time spending. Therefore, if you are unsure of a positive result, it is better to entrust the work to professionals or use ready-made compositions.

Application Tips

When carrying out work with your own hands, everything should be carefully prepared. Containers and mechanical devices will be needed. The base must be cleaned of dirt, dust and foreign particles.

It should be noted that the mixture is prepared in such an amount that it is enough for an hour of work. After this period of time, the composition begins to harden, losing its properties. Fireclay solutions can be used within 40 minutes, and lime compositions - within 24 hours.

The masonry mix retains liquid well, so there is no need to wet the base before working with it.

All work is recommended to be performed at temperatures from 10 to 35 degrees above zero. The exact temperature is indicated on the packaging.

The layer of the mixture to be applied should not exceed 10 mm. When designing chimneys, especially the part that faces the street, as well as when laying the foundation, it is not recommended to use clean clay mortar, since the substance quickly collapses under the action of vapors. In this case, a mixture with the addition of lime and sand is suitable.

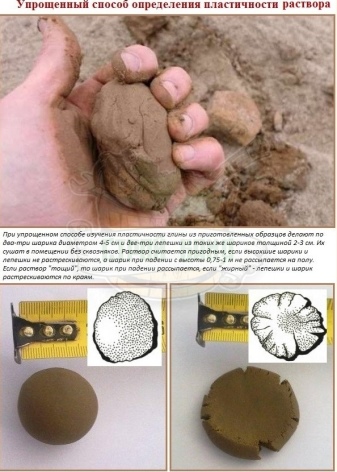

When adding clay to the mixture, it is necessary to take into account the degree of its fat content. To check the quality, you can try rolling a thick strip of damp material. Then you need to carefully try to stretch it. The formation of torn surfaces will indicate the content of a large amount of sand - it is better not to use such material.

You can use a stirring tool to check the quality of the clay. When a substance adheres to a surface, the clay is considered to be oily.If after a while a liquid appears on the surface of the clay, then the substance contains too much sand.

A mixture based on low-quality clay can soon lead to deformation, destruction of brickwork, as well as surface shrinkage.

It should be remembered that mixing medium-fat clay with cement leads to an increase in the strength of the joints, and when lime is added, the mixture hardens faster. To obtain a refractory composition, fired clay is used.

After laying the stove or fireplaces, you can start the firebox no earlier than three days later. This time is necessary for the mixture to completely harden. Facing brick masonry can be done only after a month of using heating structures, and the heating of the furnace must reach a temperature of at least 300 degrees within an hour.

When using the solution, you should follow the instructions for use. Strict adherence to the sequence of actions will ensure a positive result and high quality of the exploited surface.

Storage

It is recommended to store the ready-mixed masonry in a dry room, the temperature of which should be in the range from -40 to +40 degrees. However, some formulations are not afraid of moisture or severe frosts - they are able to maintain their properties under any unfavorable external conditions. Individual storage conditions are indicated on the packaging.

Depending on the brand and purpose of the constituent components, the shelf life of the mixture can vary from one year or more. There are refractory mixtures, the shelf life of which is unlimited. The exact information is indicated in the instructions for use.

The prepared solution can be stored from 40 minutes to a day - it all depends on the purpose, as well as the constituent ingredients.

It should be remembered that the use of an expired product is unacceptable.

For information on how to prepare clay mortar for laying a stove, see the next video.

The comment was sent successfully.