Masonry mixtures: types and their features

The masonry mix is a material that neither construction nor the finishing process can do without. Therefore, when planning repairs, you need to know at least a little about them. The quality of this product determines how durable the created structure will be.

Peculiarities

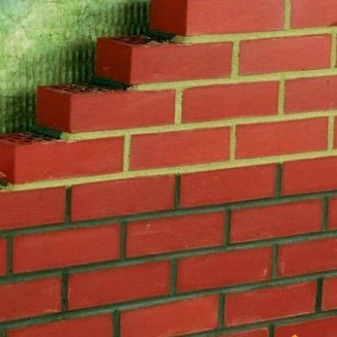

A masonry mixture is a dry material that is used for finishing joints and for laying bricks. In the process of work, the dry mixture is diluted with water, turning into a dense solution. It should not be too liquid, but, on the contrary, elastic and durable.

As part of the classic masonry mixture, there are several mandatory components, regardless of which brand the products are purchased. The main component is, of course, a binder. Without it, the solution will not be thick and elastic enough. Either cement or simple clay is most often used as a binding agent.

Also included in the composition and filler. As a rule, it is either expanded clay or ordinary sand. Most manufacturers supplement the composition of the dry mix with various mineral additives.

In order for the walls to be finished without risking spoiling their appearance, the assortment also includes colored mixtures. They contain high quality natural dye. There are not only mixtures of shades of brown or terracotta, but also brighter options.

There are several basic requirements for a dry mix. First, it must turn into a solid solution. This is one of the most important points. Indeed, the strength of the solution also determines how well the composition lays down, and how long the wall will stand. The most durable is the cement composition. Use it for outdoor decoration. Such a solution is good because it hardens quickly and is durable.

It should be noted that the strength of the mixture is especially important when working with the facade of the house and when pouring the foundation. However, if possible, it is better to choose different products.

For facades, professionals recommend using colored mixtures. The fact is that the facade is the “face” of the house, and it should definitely be beautiful. In the case of colored mixtures, you can choose a material that will perfectly match the color of the brick or finishing materials.

There are no such requirements for the mixture used for pouring the foundation. Most often, you can limit yourself to a classic cement composition with a minimum of additives. The main thing is that it is as durable as possible.

The second important point is the plasticity of the mixture. This is especially important if you need to apply a thin layer of mortar. For example, trim the base of the fireplace. The fact is that a dense layer of the product will be difficult to distribute over the surface of the wall. In addition, the plasticity of the mixture facilitates the process of finishing the joint gaps.

Views

There are several main types of mixtures. Each of them has its own characteristics that must be taken into account when looking for a suitable material.

Optimal

This type of dry mix is used during the construction of houses. Thanks to the use of such a product, the thermal insulation properties of the room can be increased. A classic red brick house will become warm and cozy if you choose a quality product. For example, a friable masonry mixture in which sand is combined with cement. The same solution is used for laying paving slabs.

In some cases, additional components are added to the optimal mixtures, which make it possible to extend the storage time of the solution. This means that if the construction process takes a long time, then such a product is perfect for the job. The composition can be prepared in the morning and fully used throughout the day.

Mixed

Another option for mixtures for installation work is mixed compositions. Such a cement mixture is much more elastic and plastic. In addition, it provides moisture protection to the room. A composition of this type is a product based on Portland cement, in which there are a lot of impurities and mineral or lime additives.

Mixed options include clay-chamotte or perlite mixtures, for example. They can be called a "winter" option, since the use of a solution on such a basis makes it possible to insulate the building very well.

Colored

In addition to the main products in gray and white, there is another interesting option - this is a colored masonry mixture. The addition of the dye does not in any way affect the density of the solution. The color mixture is a real godsend for the designer.

They allow you to decorate the wall and turn simple brickwork into something bright and original. Most often, colored mortar is used to make the brickwork look more interesting.

By the way, it is not necessary to buy a ready-made color mixture. You can create it yourself at home. To do this, you need to take a cement base. If a light shade is required, then the cement base should be white. If you want to get a darker tone, then gray cement will do. Dyes diluted in water are introduced into this base, which change the shade of the solution.

Special

Special mixtures deserve special attention. They are not used to work on a house, but for the construction of large enough buildings. One of the most popular types of masonry mix is M200.

This product has gained such great popularity due to the fact that it makes the building resistant to temperature extremes, retains heat inside the room and is quite suitable for use even by inexperienced builders.

Scope of application

Masonry mixes and mortars prepared from them can be used for different purposes. They are suitable for a wide variety of construction work, from laying tiles to finishing the facade of foam blocks, for example. Here are some of the most popular areas in which masonry mixes are used:

- Wood concrete production... From a blank, which can be bought at almost any store of materials for construction, it is possible to make such an affordable building material as wood concrete. Later, it is used either for interior decoration or for creating wood concrete blocks.

- Floor screed. Making full-fledged repairs in an apartment or a private house, you also have to redo the floor. To prepare the base for laminate, parquet or any other type of finish, a screed mortar is used.

- Construction of walls and partitions. To divide the space into several separate zones using walls or partitions, a dry mixture will also come in handy. It can be used for the installation of tongue-and-groove gypsum boards, which are well suited for the creation of modern partitions. Also, a solution from a dry mixture holds well foam blocks or gas silicate blocks made of aerated concrete.

- Installation of the foundation. Economical in common use mixtures are also actively used for foundation installation. The fact is that this material is not only resistant to temperature extremes and high humidity, but also prevents the foundation from shrinking.

- Finishing... Also, the mixtures are suitable for laying ceramic tiles, as well as for sealing joints. Colored masonry mixtures will allow you to make the walls so that they do not lose their visual appeal. At the same time, the shade of the product can be selected to match the brick, and simply at your discretion.

Manufacturers

Today there are many different manufacturers of masonry mixes.But buyers tend to prefer proven brands.

Brozex

This brand produces high-quality mixtures, in which, in addition to cement and pure sand, a set of mineral mixtures is added. Due to this, the final product turns out to be more plastic, resistant to moisture and strong.

When working with these mixtures, it is worth considering only that solutions from them should not be kneaded in cold or frosty weather. The rest of the mixes from Brozex are very good. They get a lot of positive feedback from their customers. Almost everyone who used them in the repair process is ready to confirm that the preparation of the solution is a fairly easy process. The mixtures can be mixed without problems if the instructions on the packaging are followed exactly.

The main thing is to mix the solution thoroughly and give it the necessary time to settle. The resulting product is equally well suited for filling joints and for finishing walls. The range of the company is quite large, so you can find mixtures that are suitable for a variety of purposes - from floor screed to brick laying.

Perel

Among the manufacturers of color mixtures, this particular brand is worth highlighting. The reaction of buyers to their product and the wide choice are also pleasing. In the assortment of the brand, you can find 14 different shades that will help to translate a variety of creative ideas into reality.

By the way, all color mixtures are presented in two versions. One summer, the other winter. The first option is suitable for hot weather and can withstand heat up to thirty degrees. The second one can be used in cold weather. Such the solution withstands harsh cold, which is ideal for our cold country.

Perel mixes have a good composition. There are no additives in cement that spoil the quality of this base; fractional sand is used. The base is supplemented with polymer additives and mineral pigments. The material is consumed economically, so a 20 kg package is enough for repairs.

In addition to these brands, firms such as "Terracotta" or "Osnovit"... They are quite common, so it is not difficult to find a masonry mix from the right manufacturer in a building materials store.

Advice

The masonry mixture is actively used for the preparation of mortars. It is very simple to make it yourself, and even a novice builder can cope with this task. The most popular home-made mortar is the one used in the bricklaying process.

To prepare the solution, you need a very small set of basic tools. First of all, it is a metal strainer. Even if the mixture is very good, it is still worth sifting so that nothing superfluous gets into the solution. For this, a sieve with very small cells up to 3 mm in size is suitable. From the containers, you will also need dishes for mixing the base, and, if necessary, also for adding dyes. You will also need a shovel and, of course, the mixture itself.

Another important recommendation is that you always need to calculate the amount of mixture that will be used. Due to this, you can not only save money, but also simplify the repair process, because you do not have to postpone work in order to go and re-purchase everything you need for construction. If you cannot calculate the required amount of materials, then you can contact the consultants in the store.

The kneading process is one of the most important. After all, it depends on this how well the work will be done. First of all, it is important to adhere to the proportions indicated on the package. The mixture is stirred with water and then left alone for a few minutes. This time is already enough for all components to swell.

Do not overexpose the solution. Likewise, it is not recommended to knead too much product at once. Due to the fact that there is cement in the mixtures, the solution hardens very quickly.

In order not to transfer the product and not to increase the consumption, before preparing the solution, it is necessary to re-calculate the volume of the room and estimate approximately how much solution is needed.

The work with color mixtures is also worth noting. Coloring agents are added to the solution separately. They should also be prepared in advance by dissolving in warm water. This colored liquid is poured into the main container, where the mixture itself is added.

It has already been said that it is preferable to choose a product from a trusted company. It is best if the brand has a certificate confirming the quality of the product. Whenever possible, when faced with an unfamiliar manufacturer, it is advisable to check what reviews are left about it.

Safety rules at work are also very important. Of course, a mortar from a masonry mixture is not a very harmful product. But you still need to be careful during the construction or installation of walls and partitions.

This is especially true if some modifying substances are added to the solution, for example, additives that contribute to faster hardening of the composition. They are, of course, necessary and useful, but they can harm the human body.

For safety, you need to knead the product with gloves, working as carefully as possible. You also need to use either a shovel or special tools to stir.

It is very important to determine not only whether the mixture is of good quality, but also how good the hand-made solution is. In order to understand whether it was possible to cope with the task at hand or not, it is enough just to look at the mixture. A high-quality mortar from masonry mixes always has the consistency of thick sour cream. Additionally, it is worth scooping up some product with a shovel and seeing how quickly the solution spreads. Drops should drain slowly.

Further, the product, as already mentioned, should be applied confidently and quickly so that the product does not freeze and harden. Regardless of the purpose for which this building material is used, quick and efficient work will only improve the result.

Masonry mixes are different, and it is worth buying them, clearly focusing on your needs. It is from this, as well as from the responsible attitude to the preparation of the solution, that the result of the repair depends. Knowing all the features of the materials, it is much easier to cope with the task of choosing the ideal composition. So you don't have to worry about the lack of experience as a builder and work with masonry mixtures yourself.

How to prepare a colored masonry mixture, see below.

The comment was sent successfully.