Types and best models of quick-clamping clamps

Quick-clamping clamp - a device designed for quick fixing of the workpiece. The tool is used for carpentry and locksmith work. Today's conversation will focus on the device of the device, its principle of operation, varieties and selection criteria.

Device and principle of operation

The quick-clamping clamp is a universal mechanism that resembles a kind of vice. The tool is used to fix metal parts during welding. Some types of devices are used when sawing or gluing wood blanks. All quick-clamping clamps differ in design, shape and dimensions.

Tool design looks like a metal rail. On one side of the bar there is a fixed jaw, on the other - a movable one with a trigger. The trigger is a special mechanism with two handles. The fixing of the parts takes place by clamping these handles.

Such a design device allows the master to work with one hand. In this case, the clamp has a significant clamping force for reliable fastening of workpieces.

The quick-release clamp has one advantage. If you turn both lips of the tool in opposite directions, you get a spacer device. Therefore, the quick-clamping clamp is considered universal device. In the manufacture of devices, the following materials are used: metal, wood or durable plastic.

Views

There are the following types of clamps.

- G-shaped. The product is made from tool steel by forging. It has excellent fixation and makes it possible to fasten several metal workpieces at once. Has a fine thread lead, which guarantees a good clamping force. This function is often used in welding work.

- End... The cast or forged construction resembles the letter "C", equipped with three clamping screws, which are located at right angles to each other. The type of tool is suitable for working with wood products. The mechanism provides reliable grip and fixation of surfaces. Therefore, end models are very popular with joiners.

- T-shaped. The body of the device has a guiding profile in the shape of the letter "T". Profile length - up to 1 meter. The profile has movable jaws. The clamping force is created by a screw with a handle, which is connected to one lip. The tool is used to work with sectional parts in the assembly area.

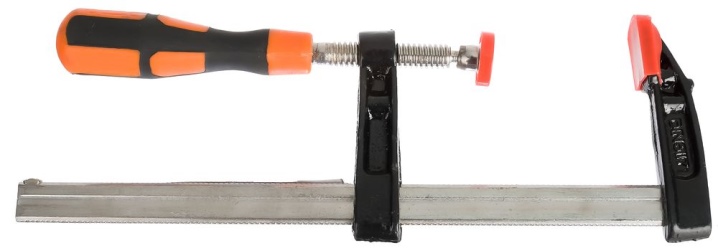

- F-shaped. The tool is equipped with a wide adjustment range. A fixed lip is located on the rack structure, and a movable lip with a movable screw and washer installed on the opposite part. The average clamping width in these models is 300 mm. Depending on the model, the length of the rail can be up to several tens of centimeters. This makes it possible to fix several products at once.

- Corner... The design of the corner clamp is easily recognizable and has several types: magnetic and screw. The screw type is used to fix wood parts. The cast body with multiple protruding parts allows the workpiece to be positioned at a 90 degree angle. The clamping force is provided with a single screw. The presence of through holes provides for fastening the structure to any surface.

The magnetic tool is used for welding.Such a device provides accurate positioning of metal workpieces.

- Tape. The clamp has a narrow specialization due to the special design of the body. The tool is equipped with a tensioning structure and a strong belt or synthetic band, which gives an even load on the parts being pulled. The device is common among carpenters and coopers.

- Pipe. The design has the form of a tube with a sponge, which is motionless. The second jaw moves along the tube and has a retainer that stops it. The downforce is generated by a screw with a handle. Most often, the tool is used in the manufacture of doors or countertops.

- Spring loaded. This type of clamp resembles a clothespin. Clamping of parts is carried out using a spring mechanism, which makes it possible to regulate the clamping force. This version of the tool is considered easy to use, since one hand is involved during work. A small grip is considered a downside.

- Automatic quick-clamping clamp. It is also called pistol due to the presence of several handles, which lead to compression of the workpiece. The lightweight and durable nylon body of the tool allows it to be used in all conditions.

- Lever. The main feature of the instrument lies in the name. The mechanism is equipped with clamps (levers), which have a quick fixation. During operation, the device does not require much effort.

Clamps are also categorized

By clamping method

The classic tool has a screw mechanism that moves the moving part of the structure. The clamping force is regulated by the master himself. Therefore, the work is carried out in both hands. Quick-release devices are more convenient, since fastening and unclamping of parts is carried out with one hand.

By effort

The clamping mechanism is responsible for the reliability of fixation. In some models, the force value can vary from 20 kg to 1 ton.

By weight and materials of manufacture

Steel and cast iron clamps are of high quality and reliable. But it should be borne in mind that such devices are heavy. There are cast aluminum models and mechanisms made from synthetic raw materials. These models are lighter and more durable.

By functionality

There are tools with various options for adjusting the clamping angle, clamping force, jaw rotation, which greatly expands the capabilities of the device. Some clamps can be used as a spacer.

Manufacturers

The overview of the best models is opened by the quick-clamping clamp BAHCO QCB-900. The mechanism is designed for fixing dimensional parts. Main characteristics:

- rail length 900 mm;

- rubber pads on the sponges;

- the possibility of fixing parts made of wood and metal;

- easy control due to the rubberized handle with the trigger;

- pressing the trigger adjusts the clamping force of the workpiece;

- the presence of a system of stiffeners.

Automatic keyless model Topex 150 mm 12A515. Peculiarities:

- frame made of durable plastic;

- capture width - 300 mm;

- clamping depth - 60 mm;

- rail length - 320 mm;

- quick clamping of jaws;

- suitable for repair and locksmith work;

- weight - 0.5 kg.

Model Inforce 90x300 mm. Main characteristics:

- clamping width - 300 mm;

- depth - 90 mm;

- frame made of steel;

- high strength of the fiberglass handle;

- a convenient tool does not cause a feeling of fatigue when working;

- used in the installation area for work of any complexity.

F-shaped quick-clamping model Gigant 500x120x600. The tool is designed to fix workpieces during gluing or when sawing. Peculiarities:

- metal case with a guide;

- comfortable handle;

- pads on the sponges exclude deformation of parts;

- clamping width - 500 mm;

- depth - 120 mm;

- length - 590 mm;

- weight - 1.9 kg.

Quick-release device with locking device Hardax 200 mm. Peculiarities:

- provides a high clamping force, which allows you to perform complex types of work;

- clamping width - 200 mm;

- durable metal construction;

- tool length - 385 mm;

- weight - 0.57 kg.

Pistol model "Cobalt 450 mm 244/735". The quick-release tool allows for enhanced fixation of parts without much stress on the hand. Main characteristics:

- plunger mechanism that provides high clamping pressure;

- nylon case with fiberglass;

- carbon steel rack structure;

- clamping width - 450 mm;

- depth - 80 mm;

- device length - 65 cm;

- weight - 0.72 kg.

Model Quick Grip XP450 Irwin 10505944. Features of the quick-clamping mechanism:

- Reinforced guide prevents the tire from bending and ensures a long service life;

- the ability to perform gluing work with a clamping force of up to 270 kg;

- clamping width - 450 mm;

- depth - 92 mm;

- special pads on the jaws, allowing you to fix even the most uneven workpieces;

- transformation of the tool into a spacer;

- protection against slipping of parts during fastening;

- 2-position expanding mechanism for safe operation;

- device length - 690 mm;

- weight - 1.5 kg.

How to choose?

The choice of any locksmith tool depends on the purpose. When buying a quick-clamping clamp, there are two main characteristics to pay attention to: the working stroke and the distance between the clamping parts. The higher the value for these two indicators, the better the tool. High performance makes it possible to use the device to work with both large and small products.

For welding work, choose the G-shaped model. It has a reliable fixation of metal parts. Also, the device has a high clamping force, which is considered an important factor when welding pipes. The material and weight of the tool also play an important role in the selection. For household work, it is recommended to purchase products weighing up to 1 kg. There are models weighing more than 5 kg. They are used in industrial production and for working with large workpieces.

Many models are protected against corrosion. This is important if the instrument is located in a damp room. For coating, electroplating and paints and varnishes are used. Some manufacturers use a powder coating type. The main feature of powder protection is the smooth operation of the clamp for a long time.

It is also worth turning to additional devices... Many clamps come with a T-handle that adjusts the clamping force.

To protect wooden blanks, manufacturers equip the jaws of the clamps with special soft pads.

Another selection criterion is the method and clamping force. In this case, the choice depends on the direct purpose of the tool. For working with large metal workpieces, it is recommended to choose a powerful device. If you intend to work with wooden parts that need to be glued or sawed, then you can choose a pistol quick-clamping mechanism. It will allow you to securely fix the part without damaging the surface.

The width of the fixing jaws is determined by the width of the parts that will be used in the work. The parameter value can range from 200 to 500 mm. There are models with wide functionality.

For example, in some models, the jaws can be rotated 180 degrees and the device can be used as a spacer.

When buying, you should pay attention to the thread on the screw. It is recommended to purchase accessories with a coarse thread... Devices with shallow threads have insufficient retention. The secondary criterion for choosing a clamp is the handle. In this case, the user himself chooses the type of handle for his convenience. The best option is an ergonomic wooden or rubberized handle.

The quick-clamping clamp is considered a universal tool for locksmith and joinery work. The design ensures secure fastening during welding, sawing, drilling or gluing. There are many models that differ depending on the purpose.

The choice of the clamp is strictly individual and depends on the tasks. These recommendations and an overview of the models will help you choose a reliable, high-quality tool.

For quick-clamping clamps, see the video below.

The comment was sent successfully.