Corner clamps for furniture assembly

Assembling furniture is not an easy task, and many different tools are used to accomplish it. The corner clamp is one of them. This device is a real assistant for the furniture assembler.

Features and purpose

The main purpose of the clamp is to temporarily fasten the elements of the furniture structure. The angular type of tool allows you to connect parts at right angles. Some models of clamps are capable of changing the angle of connection of parts.

The clamp is a kind of universal vice that securely fixes the workpieces in the desired position.

Fixed parts are much easier to connect together, they are easy to work with, and the result is high quality. And also the time to work is reduced, and there is no need to attract additional workers to help. Using this tool does not require much effort on the part of the user. It is easy and fast to work with it.

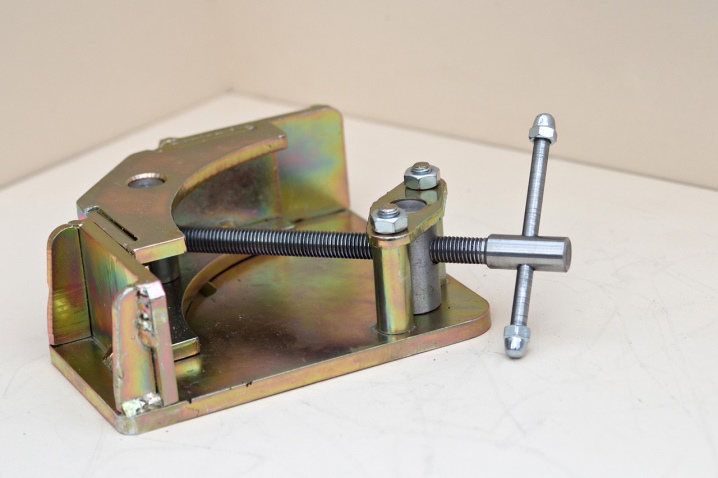

The corner furniture clamp is created in different versions. In its classical form, the structure looks like a simple and compact furniture clamp, which allows you to fix composite structures at right angles. Such a tool consists of a body, screw-type clamps and clamping heels.

Corner furniture clamps are used to assemble furniture. This is their main, general purpose. There are actually many different uses for such a tool:

- fixing parts for sawing off excess parts;

- making screeds when assembling furniture;

- corner fixing greatly facilitates the assembly of cabinets, drawers and other similar structures;

- production of structures made of wood, profile metal, frames, furniture.

This tool is used not only by furniture assemblers, but also by welders and locksmiths. With the help of a clamp, you can fix almost any part that fits the permissible tool dimensions.

Materials (edit)

If we consider an instrument made on an industrial scale, then the main material for its creation will be duralumin and alloys based on it. Such clamps have a considerable cost, standard dimensions and performance characteristics. When assembling furniture or performing welding work, it will be difficult to get by with one clamp, therefore you will have to buy several tools, and this will cost a decent amount.

Homemade tools can be made of iron or wood. Iron clamps are required for welding. Tools for a one-time job can be created from scrap or the most affordable materials, for example, from plywood.

Clamps for assembling furniture must be made of wood. For such work, parts made of birch, hornbeam, beech and larch are most suitable. This choice of wood is due to its good reshaping ability, excellent strength and high resilience.

The above types of wood are superior in hardness to materials that are traditionally selected for furniture. So that the details of the future product are not deformed from mechanical stress, wooden, leather or felt heels can be used. Light-colored rubber is a good option. Wooden corner clamps are used for working with wood.

Frames are made of wood or rolled metal in the form of shaped corners or pipes. Metal parts are pre-cleaned and painted, which eliminates the formation of scratches and traces of corrosion. Additionally, wooden planks are glued to metal parts.

Optimum smoothness of workpiece tightening control is provided by a threaded rod with a straight profile or in the form of a trapezoid. Wood can be used to create the handle. You can also make a hole in the hairpin and insert a lever bar. A tool with such a design will be characterized by high strength and durability.

Manufacturers

For a full acquaintance with the corner clamps, it remains only to get acquainted with the most interesting offers that are present on the Russian market.

- Model from Top Tools with a maximum jaw spread of 75 mm, it has an aluminum body and a pair of clamping screws. Light weight, compact size, convenient adjustment of the clamping force and affordable cost - these features attract users. The tool can be fixed to the workbench. The disadvantages include the shallow depth of the jaws, which makes it impossible to work with large workpieces.

- Wolfcraft Spring Angle Clamp - this is a more serious tool that is equipped with a movable jaw. This feature makes it possible to fix workpieces with different thicknesses. Compact dimensions, well thought-out design and convenient operation are the main advantages of this model.

- Power angle clamp from Bailey Stanley has a die-cast aluminum construction that can withstand high loads. The upper jaw is equipped with a hinge mechanism, which makes it possible to clamp parts of the same and different thickness. This tool can be used to fix parallel parts.

Selection Tips

When choosing a corner clamp in a store, looking closely at designs for self-production, you need to take into account some of the nuances.

- Initially, you need to take into account the type of work that will be performed using this tool. Particular attention should be paid to the angle at which the joining of workpieces is possible.

- The thickness of the clamping jaws determines the quality of the fixing of the parts. If the clamp will be used not only for working with wood, but also for welding, then the screws must be made of copper.

Application methods

The process of joining the two parts is greatly facilitated by the use of an angle clamp. This tool supports and locks the workpiece securely in position.

Clamps are very easy to use. To do this, you just need to adhere to simple rules:

- the angle of the tool must be strictly straight, without deviations;

- from the turn of the handle, the heels, which fixes the parts, begin to converge, thus clamping the workpieces;

- with the reverse rotation of the handle, the heels are unclenched - and the workpieces are released;

- in a fixed position, the assembled parts can be drilled without problems;

- some work requires additional fastening of the clamp with a vice to the workbench.

The area of use of corner clamps is extensive and varied:

- assembly of a wide variety of furniture structures;

- creation of various elements from wood, from door or window frames to unique designs;

- welding of metal parts.

For information on how to make a corner clamp for assembling furniture, see the next video.

The comment was sent successfully.