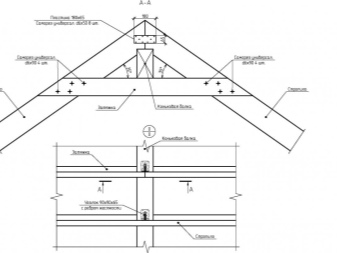

The connection of the rafters in the ridge

The connection of the rafters in the ridge and their fastening to the timber is very important for the competent construction and reliability of the functioning of the home. It is necessary to figure out in advance how to connect the rafters with an overlap. But there are other docking options that also need to be studied properly in order to avoid problems.

What are the nodes?

The roof frame is assembled from a variety of thoroughly fastened parts. However, the rafters play a key role in terms of operation.

You have to pay a lot of attention to fixing them on the Mauerlat and docking with each other, otherwise it is impossible to ensure the proper functionality of the roof and its safety.

In addition to common connecting elements, there are also those that allow you to increase rigidity. In addition to the nodes of the ridge joint, there are also nodes:

-

connecting the structure with the roofing "foundation";

-

connection of auxiliary parts;

-

docking of stacked rafters.

Choice of fasteners

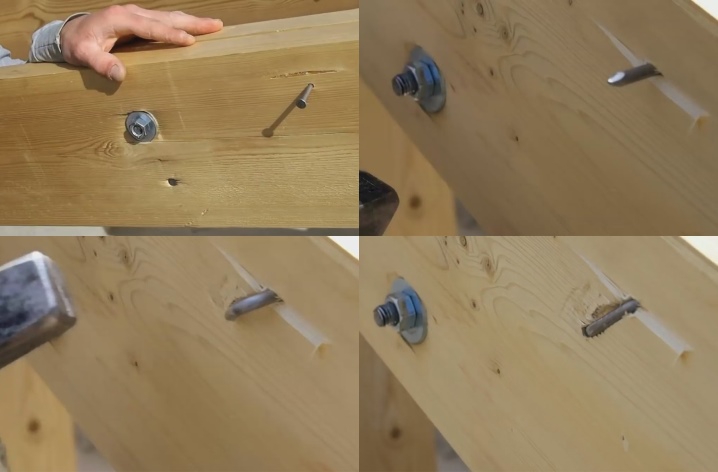

The upper sections of the rafters can be connected in various ways. Quite often, plates are used for this purpose. With a butt joint, pairs of nails with a size of 15 cm or more are used. The overlays can be made of wood or metal - there is almost no real difference between them. But you need to understand that wooden lining is attached to nails, and steel products will have to be bolted. If you need to overlap the rafters, you need to take bolts or stud-washer complexes.

How can you connect?

Roof support frames are subject to significant stress. Therefore, an accurate calculation of the entire structure is of decisive importance.... The ridge block is formed by connecting the legs of one pair of rafters. The mechanical effects on him are enormous. Often, the connection of the rafters in the ridge is made end-to-end.

The technique involves filing one of the edges of the boards, which are put on these "legs". The filing angle is selected very clearly. It should form immediately upon alignment and should not require a tedious, precise fit.

Otherwise, the structure will corrode to the sides at any significant load. This type of rafter installation is designed for the use of nails.

They will have to be driven into the butt. Be sure to make sure that the nail is passed through both legs. Strengthening the joint is achieved through the use of special plates. Holes for the introduction of self-tapping screws must be prepared in them. Such plates will be securely mounted only with a careful approach.

A serious problem is that the attachment to the timber and the log has additional subtleties. Even high quality wood can change its size due to fluctuations in humidity. The effect of shrinkage is especially great in the first 3-5 years after the construction of the dwelling. The way out is quite simple - you need to fix the rafters using special movable mounts; these are not simple plates, but connected by a high-quality steel rod. For work you need:

-

measuring tape;

-

hydraulic level;

-

pencil or marker;

-

fasteners;

-

screwdriver;

-

hand saw (hacksaw).

Specific options for attaching the rafters to the ridge for any connecting node are selected during the calculation and design process.

You can eliminate confusion by putting the required information on the drawing. Manufacturing should follow a single, pre-planned template.

The holes for screws or bolts should be larger than the fasteners themselves; this is the only way to ensure prevention:

-

warpage;

-

cracked areas;

-

other deformations.

Theoretically, the methods of connecting rafters with bolts, nails and self-tapping screws are equivalent. All three of these types of fasteners should not be buried under the surface of the boards. Be sure to provide at least a modest gap. It allows just to exclude mechanical destruction of wood during fluctuations in humidity. In this case, all connections should initially be fastened tightly, but not excessively tight.

Joining to the run is not provided. Moreover, their attachment there is technologically contraindicated. Overlapping fixation means that the legs of the rafters are joined not by the cut end parts, but by the side planes. This particular method is simpler than all other methods of execution.

In addition, the formation of a template helps to facilitate your work; according to him, the rafters are created and assembled on the ground, and then lifted onto the roof.

In some cases, another option is used - docking on a run. Often in such situations, they speak of a "ridge bar". The legs are cut at the top in a similar way. However, the attachment is already done on one leg, and not two at once. The fixing bar must be horizontal.

Some situations require the use of a swivel joint. It involves the use of plates and pins in the assembly. Ideal geometry is not maintained - but it is not necessary. On the contrary, expansion is achieved in the upper part compared to the lower element. It is worth considering that all the recommendations, including how to properly trim the rafters and ridge, usually refer to the placement of the retaining wall exactly under the ridge - and sometimes they encounter its offset location.

The differences are as follows:

-

girder equipment is recommended to improve mechanical stability;

-

correct tightening helps to improve the stability of mechanical properties;

-

the cross-section or step of the rafter is based on the span of the largest rafter leg - but the opposite rafter must have an excess of strength reserve.

Helpful hints

The fixing of the rafters on the ridge girder is usually done with a steel corner. Alternative - use of overlays or angle brackets. You can attach all these structures using self-tapping screws. The spacer effect is ensured by the transoms. It is necessary to attach the rafter elements to the girders individually, one by one.

Staples and nails are less comfortable than plates. Studs are considered to be the best fastening method. But they require a specially drilled hole. The necessary strength is provided by the lining of large washers. Reinforcement with grovers and locknuts is also recommended.

The comment was sent successfully.