Thermal profile: description and scope of use

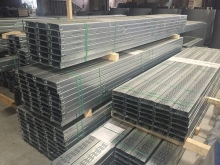

Currently, special thermal profiles are increasingly used in construction. These structures are used in the production of frame structures (LSTC), since they have special requirements regarding thermal conductivity, which must be minimal. Today we will talk about the main features of such products, as well as what types they can be.

Peculiarities

The thermoprofile is most often produced from galvanized steel using the cold-rolled method. Perforation is applied to their central part, it will subsequently become the main protection against heat leakage. Moreover, the placement and dimensions of the holes must be clearly calculated. The heat fluxes that go outside begin to pass through the perforated surface as long as possible, because all the holes are staggered in several rows at once. As a result, some of the heat simply returns in the opposite direction.

From the street, the cold will penetrate into the same perforation, but at the same time, during the period of its passage through the profile structure, it has time to heat up enough. Structures made from this type of profile can boast of durability, high quality, reliability, relatively low weight and easy installation technology. Some models of thermal profiles are available with additional stiffeners. They will allow you to withstand maximum weight loads. They are more often taken for load-bearing structures.

Technical requirements

All the basic requirements for the quality and production of thermal profiles can be found in STO 42481025 006-2007. It includes there are also references to GOSTs, which are used in technical specifications for the production of profiles.

These regulations indicate the definition of thermal profiles, as well as the key requirements for the initial material used (thin sheet galvanized steel). In addition, it also talks about geometric accuracy (the level of curvature should not be more than 0.1% of the length).

Types and sizes

Thermal profiles can be produced in various designs. The most common options should be highlighted.

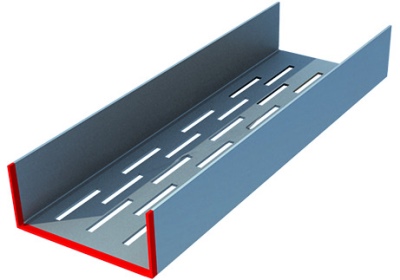

- U-shaped guides. This design is made from molded steel tape. In the manufacture, carefully processed metal is used, which will not undergo corrosion during operation. These profiles are absolutely smooth products that are used to form the base of the frame structure. U-shaped models of guides can be produced with a width of 100 mm, 150 mm, 110 mm. Their thickness can vary from 0.8 to 2 millimeters. U-shaped models can be produced in two different versions: PP and CCI. The first variety is used for purlins; it can be taken for horizontal elements that do not require thermal insulation. The product is mainly purchased during the construction of summer shower cabins in the country, small buildings for household purposes. The second option is needed for horizontal purlins of load-bearing external walls, which require good thermal insulation.

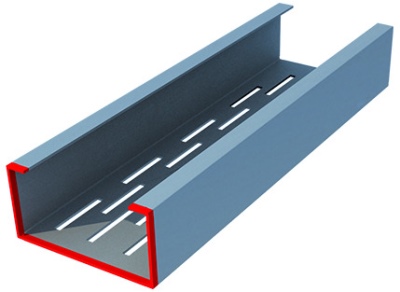

- C-shaped profile. Such a bent specimen of the characteristic C-shaped shape has rather large bends, which makes it possible to impart good rigidity to the entire structure. These samples are often designated by the abbreviation PS or TPN.The first option is a rack profile designed for vertical elements that do not need thermal insulation. The second option is used for vertical exterior wall coverings that require thermal insulation.

- Z-shaped profile. This model has a characteristic strong bend. It can also be produced in two variations. One type is a metal product that can be used both outdoors and indoors. The second type is purchased together with an insulation material for the interior of structures - this will not only significantly increase the thermal insulation characteristics, but also easily hide communications.

- Hat profile. This steel type of thermoprofile has an unusual omega-shaped shape. It is most often denoted by the short abbreviation SHP. The model will be perfect for creating roof lathing and wall coverings. In addition, the cross-section of this shape allows you to significantly increase the stiffness indicator, therefore, hat options are also widely used to create wickets, swing gates, and various sliding structures.

In building stores today, you can see a wide variety of thermal profiles, depending on their size, but the most common models are with values of 250x65x2, 150x45x1.5, 200x45x1.5, 100x42x2, 150x42x3 millimeters.

Application area

Special thermal profiles can be used in the construction of a wide variety of structures, including residential ones. But more often it is purchased for the construction of the frame part of a residential building, for the formation of a base under the roof. Houses made of LSTC are the most durable structure, consisting of thermal profiles both from the inside and from the outside, and all this sheathing is filled with mineral wool insulation. Such structures are budgetary, but at the same time durable and reliable buildings. We must not forget that during the construction of frame buildings from this material, it is necessary to have a special supply and exhaust ventilation - it will ensure good air exchange.

Thermoprofiles make it possible to completely rebuild partitions, roofing systems. It can be used as a lathing material for additional insulation of the facade with mineral wool or expanded polystyrene plates.

Sometimes the walls of buildings are formed from such a building material. In this case, the design of small dimensions is made entirely. Longer options are best created in separate sections, which are subsequently fastened together. To ensure the required rigidity in the corners, you should use special parallel ligaments or kosoura. Often, the frame part of the trusses is built from the thermoprofile. In this case, the more the span between the walls becomes, the more rigid the roof should be. Further fastening of the walls to the frame is done using special metal corners. Small slopes of such trusses can be made in the form of frames that are installed on a steel ridge.

This profile will be a good option for the construction of the attic of the house. You can make a closed-type wall frame, after which the rest of the materials will be mounted on it. And you can also build a closed frame along the top of the walls and adjust the support posts to the roof level. All individual components of the frame structure are fastened with bolts or self-tapping screws, which makes their installation as simple and quick as possible. They can be easily disassembled if necessary, so they can be mounted elsewhere.

The comment was sent successfully.